VARTA lends it expertise and experience to predict how ‘increased pressure’ to go electric will impact the independent aftermarket and how the battery manufacturer can steer customers in the right direction.

As higher emission restrictions imposed by governments around the world come into place, and a consumer mind-shift to greener options and more environmentally friendly footprints, vehicle manufacturers (VMs) have come under increased pressure to go electric.

The UK government ban on petrol and diesel car sales by 2030 is not an uncommon approach in achieving a reduction in emissions – most European countries have similar plans to enforce the restriction on traditional internal combustion engine (ICE) vehicle sales.

As drivers become more accepting of electric vehicles (EVs), this is reflected in new car registrations, with full EVs expected to be 30% of European sales by 2030.

In the UK, alternative fuelled vehicles (hybrids as well as EVs) accounted for 44% of new car sales in 2021 – 10% of which were full EVs, according to GiPA; in fact, the BBC reported that EV registrations rose by 75% last year, from 108,000 to 191,000 – this is a strong indicator that the car parc is changing.

What does all this mean for the automotive aftermarket?

There are workshop businesses preparing for the changing car parc already; some forward-thinking independent workshops are taking advantage of it, by specialising in the aftermarket EV segment. News on these types of workshops report business is booming, particularly because, at present, they are few and far between and often have little local competition.

Despite all the developments mentioned above, the aftermarket should still consider that by 2030 forecasts suggest only 7.5% of the vehicle parc in Europe will be full EV. The vast majority of cars on the road will still be a mix of traditional ICE and those with a start-stop system, and so the traditional work and repair jobs carried out in workshops across the UK will remain.

VARTA Technical Trainer, Andy Cook, expanded: “Even though the very latest vehicles are increasingly electrified, the bread-and-butter business of a garage will remain for many years to come. Yes, there are those businesses preparing for the future, but garages shouldn’t be alarmed; there is still plenty of traditional work (and will be) for the foreseeable future.”

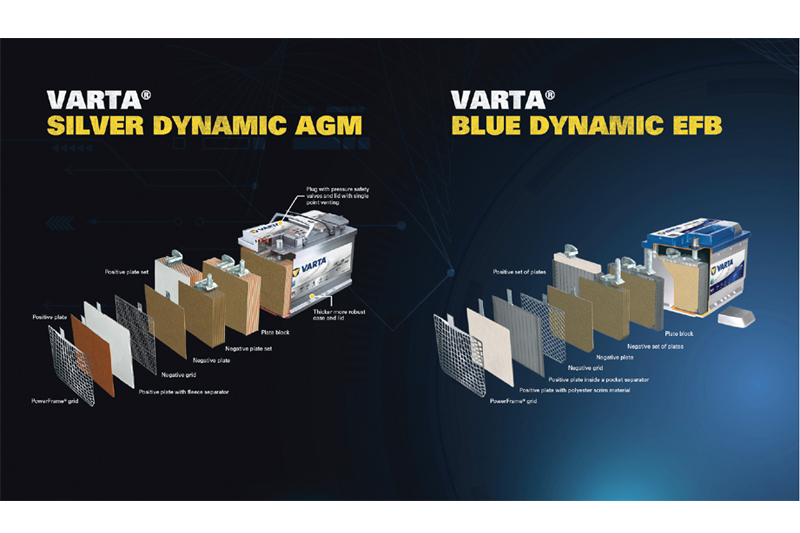

VARTA has predicted that what the vehicle parc will see developing in the immediate future is the rise of start-stop vehicles. New ICE models being released without a start-stop system are minimal, and by 2023, 53% of the UK parc will have a start-stop system. This is key for the battery replacement market, as these types of vehicles require a different kind of battery, either an Absorbent Glass Mat (AGM) or Enhanced Flooded Battery (EFB).

Andy said: “A traditional flooded leadacid battery cannot be used on start-stop vehicles, and, therefore, the aftermarket share of AGM and EFB batteries will continue to increase dramatically from 16% in 2018 to 41% in 2023.

“Factor staff and those fitting batteries in the workshop need to be aware if the battery required for a vehicle is a start-stop type, as fitting the incorrect technology can result in a vastly shortened lifespan, or some functionality on the vehicle not operating correctly.

“It is essential that an AGM or EFB is fitted to these start-stop cars, (as) an older style lead-acid battery simply will not do the job on a car that is constantly stopping and then starting again; they were not designed to handle the increased number of start cycles.”

In addition, VARTA said it is vital to have an up-to-date battery tester in the workshop, which has the capability of accurately testing the vehicle’s battery, and this includes AGM and EFB types. Many older testers will not be able to test these types, and so it is worth workshops investing in the latest test equipment.

To help understand if a vehicle needs a start-stop type battery, VARTA offers the free-to-access VARTA Partner Portal to all factor staff and technicians; the online platform uses original equipment information to help identify the correct battery for every vehicle, and also includes step-by-step fitting instructions, location of the battery, job time and re-coding information.

Access to the VARTA Partner Portal is available via all internet-enabled devices. Visit www.rdr.link/FG008 to find out more.

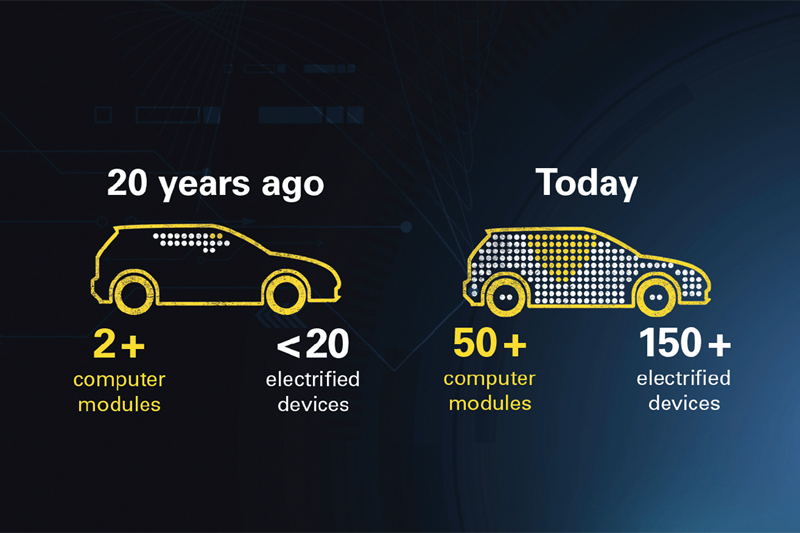

Vehicles are fast becoming increasingly software-based, with many VMs investing heavily in this direction:

- Volkswagen has recently acquired a majority stake in connected car platform, WirelessCar, and is planning to hire 10,000 digital experts in its Car.Software organisation by 2025.

- Mercedes has added over 200 software engineers to its MBition division, focusing on future technology developments for its vehicles.

- Toyota has recently announced a €1 billion investment in connected car and artificial intelligence, and many of the other big players are also significantly putting budgets towards this type of activity.

It is clear that cars being developed currently will be packed full of computer modules and electrical features – less mechanical, more software-based.