Aisin discusses two of its main product ranges: brake pads and singlemass flywheel kits.

The second most frequent reason for MOT failure is defective brakes. Aisin says that the braking system is something it takes very seriously – so much so that along with Denso, Sumitomo and Toyota, it set up a joint venture company in 2001, named ADVICS. Aisin is the lead partner with a 40% shareholding in the company. Today, ADVICS is said to be considered as a leading global supplier of brake systems. Its product portfolio includes electronic stability control, antilock brake systems, brake boosters, master cylinders, wheel cylinders, disc brakes and pads, drum brakes and shoes, and other related components.

In Europe, Aisin Aftermarket sells these parts and components under the Aisin or ADVICS brands. Whilst the focus was initially only on Japanese and Korean brands, the range has grown over the past three years, and now covers many of the more popular European applications too. Market coverage has reached the 80% threshold mark for the complete European car parc, comprising European and Asian car brands, with around 600 SKUs.

In 2016, Aisin launched branded brake pads utilising the latest brake pad materials, called OPTAMIX. The company claims the brake pads offer the following benefits to customers:

- Ecology – Absence of copper ensures more eco-friendly braking

- Effective – Brake pads are gentle on discs and cleaner for rims

- Quality – New pads generation, which improves driving comfort and braking power

- Safety – High performance pads, reliable in all situations (ECE – R90 compliant)

Kitted up

Kitted up

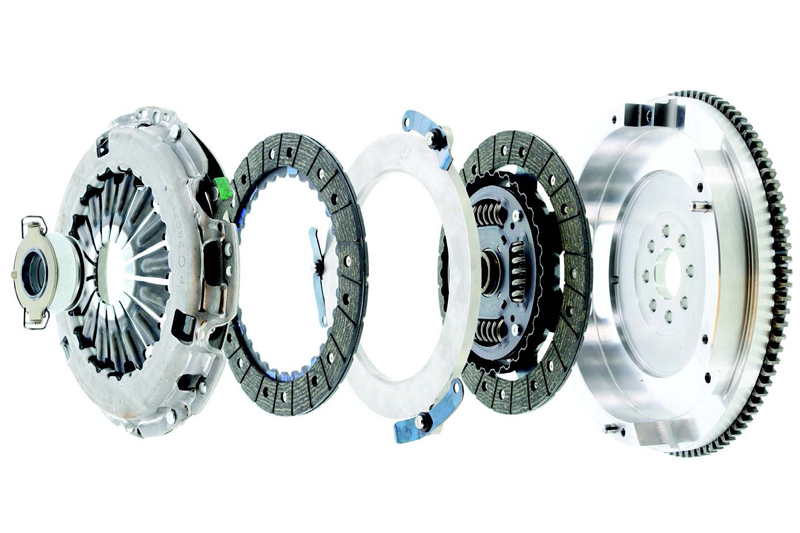

Aisin also produces over three million clutches a year for OE and aftermarket use. The company’s clutch kits combine the ideal clutch components in an effort to deliver optimal drivetrain efficiency.

Single-mass flywheel (SMF) conversion kits for an OE-fitted dual mass-flywheel (DMF) have been around for some time, and the reason is quite clear. A clutch replacement requiring a new DMF is expensive and time consuming. The DMF was developed for the new generation of direct injection, high torque diesel engines (DMF can also be found on petrol/gasoline applications). Compounding this was the drive to lower overall fuel consumption and so transmission gearing (usually the final drive) was increased to allow the vehicle to drive at cruising speeds at lower engine RPM. At such engine regimes, diesel engines are prone to high torsional vibration and if un-damped, these forces can destroy the clutch and transmission.

The SMF kit is an economic repair for an older vehicle experiencing DMF failure. However, the un-damped torsional vibration from the engine can destroy the SMF replacement and the manual transmission. For older vehicles close to end of life, it is an acceptable solution.

What Aisin Europe wanted to develop was a SMF solution that would overcome these shortcomings. Economically, the company’s Twin Disc solution will be cheaper than a DMF replacement (15 to 20%) and subsequently with the service kit, the total cost of ownership (TCO) for the vehicle will drop. However, the customer benefits do not stop there. The torque capacity is claimed to increase by 10%, allowing for greater reliability and durability. Clutch cover load might be reduced by 40%, making clutch operation easier and smoother. Surface pressure can be reduced by 60%, allowing for greater long-term reliability and durability. Finally, if the Twin Disc conversion kit requires replacement, only the friction material needs to be replaced, the single-mass flywheel now remains on the vehicle; a win-win for all concerned.