Drivers can count on NTK components to help reduce emissions and achieve impressive vehicle performance and economy, according to Niterra UK. The company believes this is a winning formula for both you and workshops.

Its EGR valve range was extended earlier this year with the introduction of two new part numbers for a number of popular vehicle applications. This follows the introduction of 45 references last March in phase one of its UK launch.

The valves – equivalent to their OE counterparts – have now been boosted by the addition of part number EGP0-N113 (stock number 93038) and part number EGP3-A111 (stock no. 97915).

Niterra UK Marketing Manager, Mark Hallam, said: “The new additions supplement our range, which cover thousands of popular cars and LCVs on UK and Ireland’s roads and further enhance the portfolio of NTK products that we supply to our aftermarket customers.”

Priority is to reduce harmful NOx

The principal function of the exhaust gas recirculation system (EGR) is to reduce the amount of harmful nitrogen oxides (NOx) that are produced during the combustion process. NOx is created when high combustion temperatures enable the nitrogen and oxygen present in the air-fuel mixture to combine. EGR valves operate by taking some of the exhaust gases from the exhaust manifold and then reintroducing these gases into the intake manifold, mixing them with fresh air.

Originally developed at the beginning of the 1970s, EGR valves were first used in Europe in the 1990s in order to meet ‘Euro 1’ emission standards. Today, every diesel car is equipped with EGR valves, while 30% of petrol cars are fitted with them. Niterra claimed many new models are equipped with two EGR types (low pressure and high pressure), which means that the replacement part market for these types of valves is likely to grow, corresponding to the level of demand.

EGTS favoured by VMs

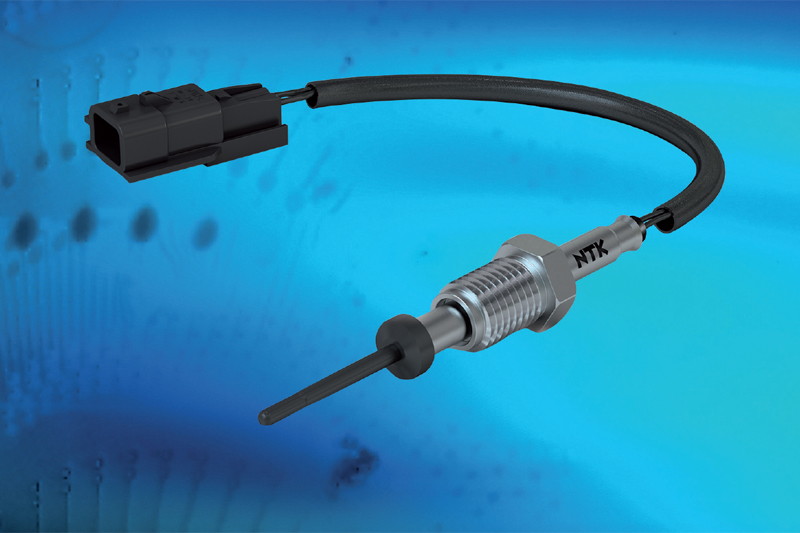

NTK sensors include exhaust gas temperature sensors (EGTS), with 38 part numbers covering 33 million cars.

EGTS from NTK are OE in approximately 35% of global passenger car sensor applications and are a popular choice for VMs, as they provide “extreme resilience” against heat and vibrations, have high measuring accuracy, fast light-off times and an “exceptionally wide” measuring range.

They monitor components, such as turbochargers, DPFs and catalysts, ensuring that they function at the optimum temperatures for greatest efficiency and protect them against excessively high temperatures that can lead to component failure. Electrical resistance of the thermistor element varies relative to temperature.

Meanwhile, NTK lambda sensors are also desired by VMs, providing the right sensor for every vehicle application. Niterra reported that these sensors offer improved engine efficiency, reduced emissions and increased economy.

Niterra urges caution when fitting ‘universal’ lambda sensors

A ‘universal’ lambda sensor is designed to cover as many applications as possible by splicing in the connector from the unit being replaced. In theory, this sounds like a good idea. In practice, according to Niterra, the potential for a mismatch with the vehicle’s system or subsequent premature failure is high.