Patrick Stüdemann, International Technical Trainer at Meyle, discusses how the company’s control arm offering expands beyond a simple product.

Mercedes vehicles with complex multi-link axles are susceptible to high levels of wear and tear. The ball joint, in particular, is often subject to wear due to the high weight and the running movements of the Mercedes models. This may lead to premature failure of the OE part, thus impairing driving safety and causing costly repairs with relatively low mileage.

This is where Meyle-HD comes into play. With a durable solution, we have expanded our portfolio of steering and suspension components. The Meyle-HD control arm for Mercedes W205 models has been technically enhanced by our engineers for the high weight load in Mercedes vehicles, thereby preventing the part from premature failure.

The increased ball diameter of the Meyle-HD ball pin reduces the surface pressure, and thus wear. During the optimisation process, we not only focused on the function, but also on the condition. An inductive heat treatment has made the ball stud even more resistant to friction and wear – and therefore simply lasts longer than the OE part. Even the grease that we use is designed for a long service life, whilst a newly designed plastic seat ensures a perfect fit.

Alongside the Meyle-HD control arm for Mercedes-Benz W205, we also offer a large range of control arm kits for, for example, various BMW, Mini and Range Rover models. In terms of the BMW and Mini control arm kits, we provide a technically improved aluminum control arm with a replaceable support joint and fastening material. The aluminum construction ensures that the control arms are very well protected against corrosion and are particularly durable. The kit consists of every component needed for both installation and removal: both control arms, matching Meyle-HD bushings – with holders and the necessary fastening material – as well as all required installation materials.

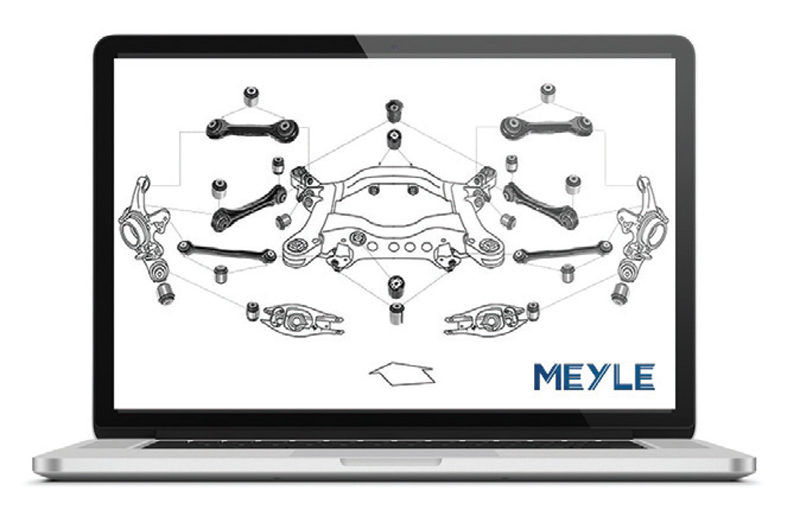

Graphic design

In order to make it easier for garages and factors to identify the required parts, we offer context-sensitive graphics of rear-axle multi-links for selected BMW and Mercedes-Benz models. These graphics show the spare part in the context of complex chassis technology, which is an enormous time saver for aftermarket businesses. When viewing the graphics, users are shown the exact installation positions, and can see all the relevant information and details when they click on the article.

Technical training and seminars for know-how transfer

On top of its product offering, Meyle also offers diversified training opportunities. In response to COVID-19, the company has decided to offer digital training sessions online to support technicians with in-depth knowledge and tips. Whether topic-related seminars – such as steering and suspension – or product-related training courses – such as on Meyle-HD parts – the training seminars are run by skilled and qualified trainers.

It doesn’t stop there; the company also offers detailed assembly instructions for many of its products that are specifically adapted to different vehicle types and manufacturers, as well as different step-by-step video tutorials.