UFI discusses the various applications of different heat exchangers, not only in conventional internal combustion engines, but in hybrid and electric vehicles too.

Thermal management of liquid-cooled systems is essential for the smooth and optimal operation of modern drivetrains. A central element of a thermal management system is the heat exchanger that can be found in various areas of conventional internal combustion vehicles, but also in hybrid and electric vehicles. They are used in conjunction with the lubrication system, the transmission system and the batteries of electrified engines, where they need to meet the challenging demands of vehicle manufacturers, as well as the ever stricter regulations towards emissions.

EV & HEV heat exchangers

Heat exchangers for hybrid and electric vehicles are designed to keep batteries within their optimal operating temperature range – between 15 and 35°C. In cold-start conditions, a battery heater needs to heat the electrolyte to avoid permanent capacity reduction of the battery. During normal use, a heat exchanger needs to cool it down, avoiding overheating and degradation of

the battery. The latest generation of UFI’s heat exchangers for hybrid and electric vehicles allows for multiple applications.

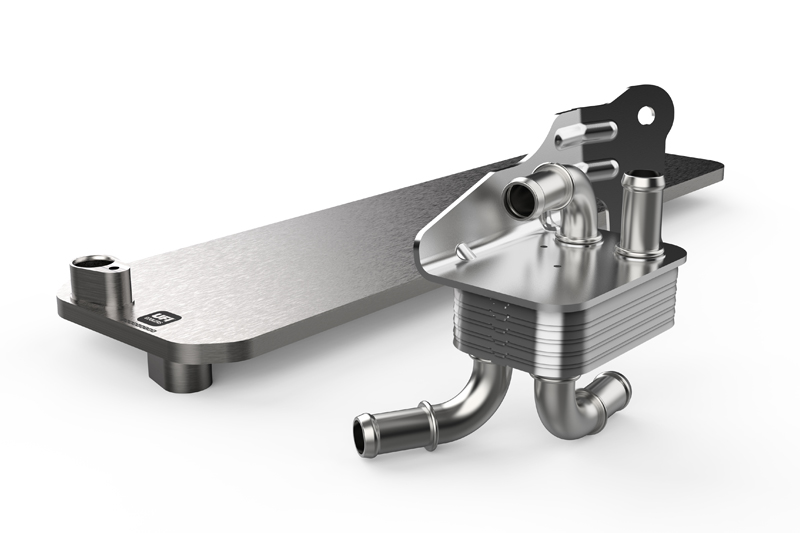

Standalone engine oil coolers

Mounted directly on the engine and designed on the basis of the specific thermal requirements of each individual engine, these are adjustable in height. UFI exchangers provide superior cooling properties, in order to effectively reduce the heat load and ensure better performance and longer engine life.

Engine oil coolers on modules

These engine oil coolers are integrated into the oil module together with the filter and, optionally, to the thermostatic valve and the electronic sensor. They have a fundamental function in the oil cooling circuit; to maintain temperatures within the established range in order to reduce consumption, limit emissions and increase engine or transmission life.

Transmission oil coolers

The transmission oil cooler is mounted inside modern automatic gearboxes. Its function is to keep the oil temperature within a determined range. They can be equipped with a thermostatic valve to either heat (cold start) or cool (engine operation) the oil with the aim to increase the durability of the transmission system, and to reduce fuel consumption and vehicle emissions.

Since entering the heat exchanger sector in 2012, UFI has gained valuable insight into the development and production of thermal management units. In particular, investment in research has led to specialisation in the design, development and manufacturing of water-cooled and vacuum-brazed aluminium heat exchangers that are lighter, more robust, more efficient and cleaner.

The company is integrating thermal management technologies by combining filters with heat exchangers and developing additional functions, such as thermostatic, anti-drain and pressure-release valves, coarse filters for coolant, sensors and integrated adaptor plates.