Lumag has revealed the results of its latest benchmarking exercise, in which the company claims its Breck brake pads and discs outperformed those of OE manufacturers.

The LU 704 brake material was tested comparatively with other friction materials from different reputable manufacturers, including a true OES supplier, and a number of aftermarket brands. The purpose of this benchmarking exercise was to demonstrate the value placed on brake pad and disc effectiveness and wear, including part longevity, performance, and how these contribute to driver safety and customer satisfaction.

Two core areas were investigated, including brake efficiency and wear (of friction material and brake disc), both of which were undertaken on a popular passenger vehicle upon a dynamometer bench.

Testing matters

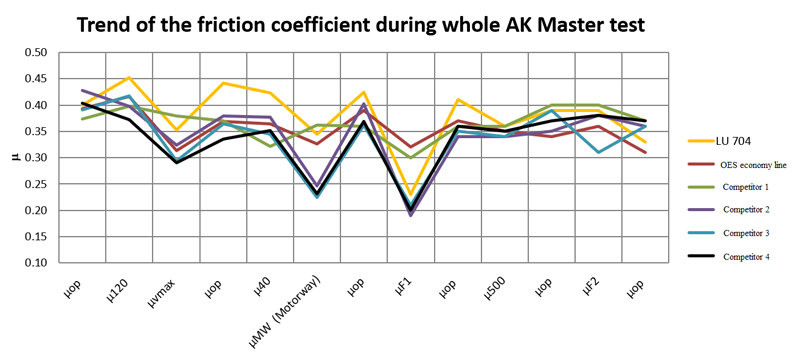

The first test – AK Master – is used to characterise the brake pads in terms of friction coefficient.

The nominal value of this coefficient is usually in the range: 0,35-0,45. The coefficient is never constant during the test, and it changes as a function of temperature, speed and pressure. Brake pads exposed to certain factors – such as high temperature – have the ability to change their properties permanently. In the ideal case, the friction pair would always have a constant value of friction coefficient.

The test undertaken by Lumag included the following criteria:

- Nominal friction coefficient

- Minimum coefficient of friction during tests

- Drop of braking performance (in %) in first and second fading

- Friction coefficient in motorway section

Brake snubs were also tested, including braking distances from speeds of 120 to 80km/h, and deceleration and the time of brake stop when braking from 120 to 80km/h. Brake snubs at constant pressure were also tested.

Placed against five competitor parts, the LU 704 material showed better braking performance efficiency than the other compared friction materials. The only exception is the first fading, when the coefficient of friction dropped to values lower than those of the OE manufacturer parts, but remained higher than the remaining competition. In all other parts of the test, the company says that Breck’s material superseded materials specifically developed for OES.

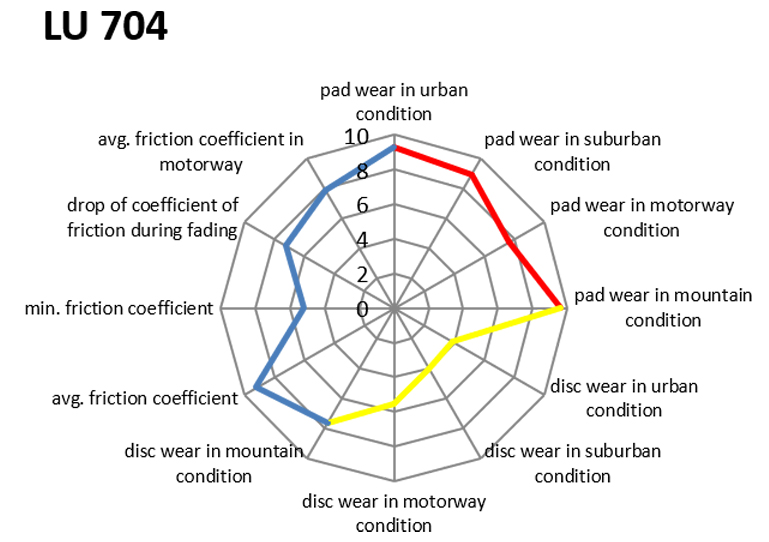

An additional wear test was also undertaken, which consisted of imitating different driving conditions, including urban, motorway, suburban and mountain.

After each cycle, the thickness and weight of the brake pads and the disc were measured. The expectation of a quality brake pad is that the level of wear upon the disc and pad would remain minimal. The LU 704 saw average wear to the pad of just 0.36mm, beating the next closest competitor by 0.05mm.

When looking at the results of the wear test, the BRECK LU 704 discs consistently performed positively, with the average wear of competitor friction material showing higher values of wear within the region of 25 to 55%. The only exception to this is brake discs that utilise a higher copper content. As a result, this may make it unattainable to achieve a true wear result.

Colin Smit, UK Managing Director of Lumag, said, “An efficient braking system is paramount to the safety of any vehicle. The fact that brake pads are still ranked by price alone is not only irresponsible, but it demonstrates a lack of understanding of the more crucial factors that provide better performance, safety and longevity of a brake pad.”