Shaftec’s Joe Toakley discusses how the company has continued to thrive despite the omnipresent threat of Brexit.

To be honest, through a combination of holding over £5million worth of stock at any one time, the Shaftec USP of our complete remanufacturing process taking place under one roof in one UK location, and because we’ve been planning for all eventualities Brexit was likely to throw at us, it’s really only had a minimal impact on the company now that it’s actually happened.

The bottom line is that our business model means that Shaftec can always guarantee constant availability, enabling our customers’ businesses to carry on, whilst competitors may struggle to get a full supply of parts into the country.

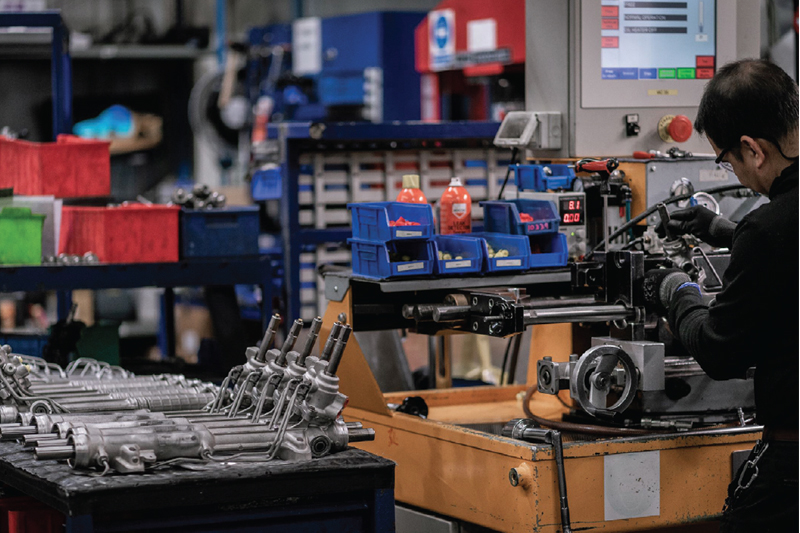

In order to safeguard the interests of our customers, all business plans over the past few years have taken Brexit into consideration. In terms of being good at things, our planning and forecasting skills are up there with our remanufacturing prowess, so we were never going to be left out in the cold! Operating under one roof – from accepting and sorting old core through to testing each product to be shelf ready – and having the room to keep a hefty stock of any ancillary parts that we do source from OE suppliers in Europe massively reduces any problems we might encounter with shipping delays.

All of this preparation was incredibly important when it came to ensuring we didn’t run into any problems supplying our customers throughout 2020. We constantly hammer home the message that range and availability are key, a message which has never been more important! This worked extremely well for us during the height of the pandemic, as availability levels remained good despite seeing an increased demand in the latter part of the year.

Because of our attention to detail, we test every individual part – there’s no batch testing here! As a result of what has become a literal obsession with stockholding, we’ve been able to not only ride the storm, but to thrive under difficult market conditions.

As we move further into quarter one of 2021, we have everything in place. We intend to focus on new to range parts to keep pace with the ever changing car parc, especially in regards to electric steering. Production is running at capacity, shelf stock levels are extremely healthy, any expected shipment delays of ancillary parts have been factored in and will not affect production levels, and with vaccinations in full swing, we can see a positive path for 2021.