With the transport sector responsible for 24.5% of global emissions, Schaeffler claims to be committed to the challenge of significantly reducing CO₂ emissions to ensure that the planet’s temperature does not increase by two degrees.

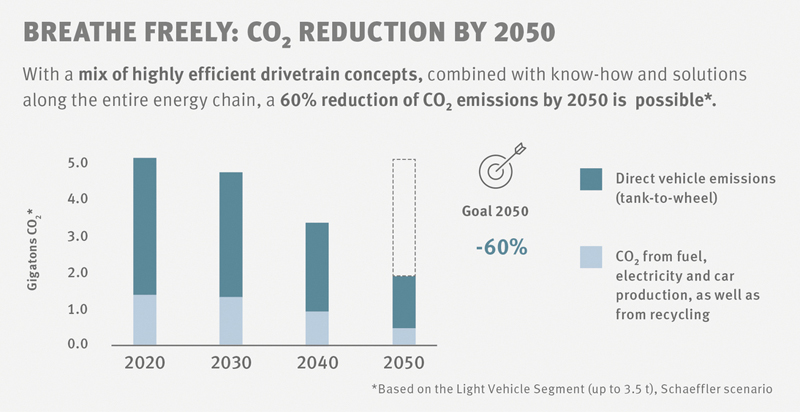

Schaeffler has pledged to play an active role in reducing CO₂ emissions by 60% by 2050, but with demand for mobility on the rise worldwide, how can it help to achieve these targets?

With what the company has labelled as a combination of highly-efficient drivetrain concepts and system solutions along the entire energy chain, it is confident that the goal is within reach.

The UK Government recently announced a decision to bring forward its ban on new petrol, diesel and hybrid cars from 2040 to 2035, and Transport Secretary, Grant Shapps, is not ruling out the ban being introduced as early as 2032.

The ban is part of the Government’s strategy to move drivers over to fully-electric vehicles, thus helping the UK meet a ‘net zero’ emissions target by 2050. This puts renewed pressure on vehicle manufacturer (VM) technology partners, like Schaeffler, to provide the components and systems to power the vehicles of tomorrow.

Schaeffler’s own research and analysis shows that by 2030, there is likely to be a 30/40/30 split in the light vehicle segment; where 30% of vehicles will still have just an internal combustion engine (ICE), 40% will have a hybrid powertrain, combining electric motors with an ICE, and the remaining 30% will be purely electrically powered.

In cities and towns, vehicle emissions are being scrupulously observed and actions are being taken to reduce them; Bristol, for example, is set to become the UK’s first city to ban diesel cars from entering parts of the city in a bid to cut its air pollution, as well as charging owners of commercial vehicles to enter a certain area.

VMs are obliged to fulfil their mandatory upper limits for emissions in the LCV sectors separately, as it is not possible to offset emission values against those of passenger car fleets. The performance of electric motors can largely fulfil those requirements, which is one reason why Schaeffler has invested in several electric powertrain projects.

For example, in December 2019, Schaeffler and Audi announced an agreement to continue their Formula E technology partnership, focusing on transmission, engine and drive concept improvement, with a target of both success and ‘sustainable mobility’.

Schaeffler claims to have already laid the foundations for providing sustainable and fit-for-the-future mobility. By providing advanced parts and systems for vehicles with integrated start-stop technology and 48V e-components to hybrid vehicles with smaller fossil fuel powered engines and pure electrics, Schaeffler is aiming to secure its place as a valuable technical partner.

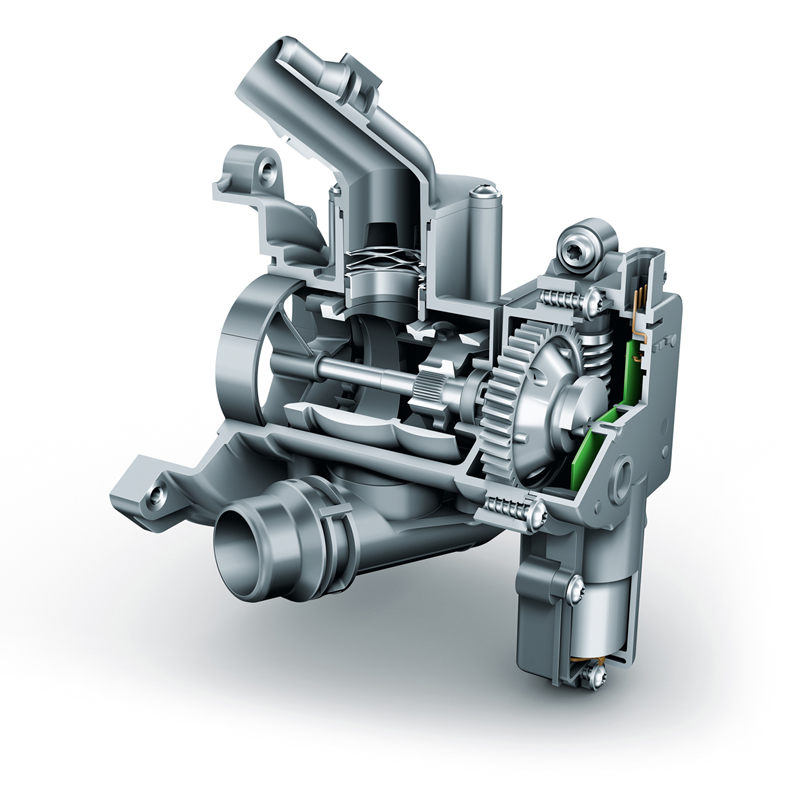

Another method of reducing CO₂ emissions and fuel consumption is by controlling engine heat flow, using a thermal management module (TMM) – coined ‘cooling on demand’. Schaeffler produces TMM units for OE fitment, which are also distributed to the aftermarket under its INA brand.

A TMM uses sensor-controlled rotary vanes to accurately regulate the temperature balance throughout the powertrain, which means that an optimal temperature can be reached quickly in additional controlled circuits, such as the gearbox, engine oil and turbocharger.

The TMM also controls engine temperature from start-up, resulting in a significantly quicker ‘warm-up’ phase that can result in a CO₂ emissions reduction of up to 4%.

For VMs, a TMM is a ‘bolt-on’ cooling system, and the INA cooling range also includes mechanical, switchable and electric water pumps, many of which can also be found inside appropriate INA KIT+ boxes, along with all the components needed for a professional belt system service.