Ecobat Battery emphasises stock control best practice

While its message to workshops is to test the battery of every vehicle that enters the premises, Ecobat Battery’s advice to you centres around ensuring you have enough battery stock – and how to best protect that investment! Its training manager, Christopher Jones, tells us more:

Although demand has naturally dropped since the flood of sales following the end of the pandemic lockdowns and returned to more seasonal norms, as has been demonstrated by the unseasonably cold weather in late November and early December, it is wise for you to carry a reasonable battery stock to be able to react to such opportunities. However, it’s equally as important to ensure that the batteries you supply are in good condition and ready to be used.

How to store them

It might sound completely obvious, but all batteries, whether traditional lead acid SLI (starter/lights/ignition), EFB, AGM, Gel – or even lithium – should be stored upright, in a well ventilated and dry storage area, with an average temperature of around 15°C, which also has the facilities to charge them.

In addition, try to keep them on shelves rather than standing on a concrete floor, but if the floor is the only option, sit them on a wooden pallet, not directly on the ground. This is not because it will in anyway affect the rate of discharge, it is simply a sensible precaution to prevent damage to the plastic case from any debris that might be on the floor, that could possibly crack it and cause the electrolyte to leak out.

To manage stock well, it’s useful to understand some of the battery basics, such as the fact that each one contains six, nominally 2V cells, which when they are fully charged hold 2.11V and 1.95V when completely discharged, so the operational window is actually very narrow, between 12.7V for a fully charged battery and 12.4V, at which point it needs to be charged as soon as possible, because prolonged periods at this level of discharge will causes damage due to a chemical reaction called sulphation.

Even when disconnected, a typical SLI battery will self-discharge at the rate of 0.1V per month, which means that a fully charged battery will be discharged to the point that it would struggle to start an engine (11.8V), in just nine months! So, to minimise this phenomenon, make sure they are fully charged when first stored, keep them clean, cover the positive terminal, and check the voltage every eight to 12 weeks. Should the voltage drop to 12.5V or below, fully recharge them immediately.

Effective stock control

This also includes rotating stock to make sure that the oldest battery of its type is sold first. So, another best practice principle is to nominate someone within the business to generally look after the battery stock and test, and if necessary, recharge them, as well as order replacements, whenever stock levels become low.

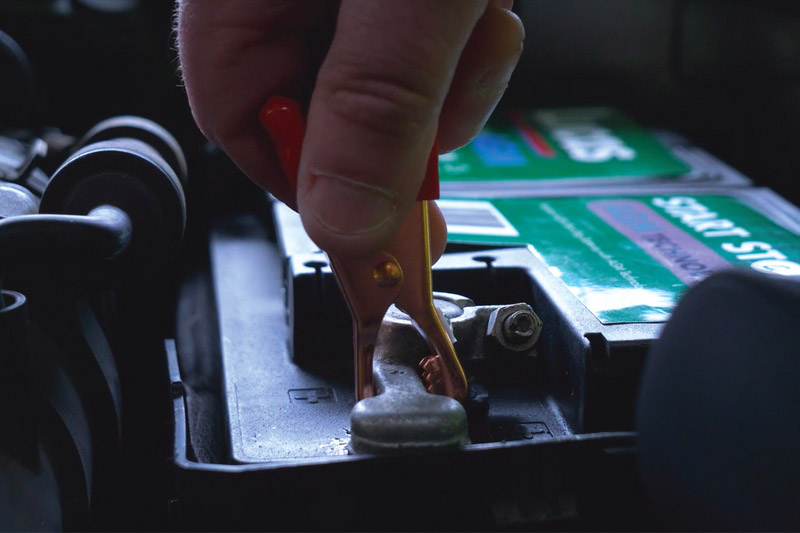

Before despatch to the customer, one final check to ensure the battery’s state of charge (SOC) is above 12.5V is required, because, obviously, your reputation would be severely undermined should a discharged battery be delivered. However, it is not necessary to check its state of health (SOH); in fact, to do so is likely to be misleading due to the fact that replacement batteries manufactured in Europe are not ‘fully formed’, which is a piece of battery terminology that needs to be explained.

Fitting a fully charged, but yet to be fully formed battery, is the best way to maximise its lifespan and performance. Being used and charged in situ helps with the battery’s overall endurance, as it goes through its final forming process over several weeks of cycles (charge, discharge, charge), during its use.

Availability vital

Naturally, when it comes to restocking, or should you urgently need a battery type that is not normally on the shelf, as the UK’s largest independent automotive battery distributor, supplying the likes of Exide, VARTA, Lucas and Numax, Ecobat Battery is ready and willing to provide the solution.

However, in addition to its ability to supply the batteries needed, when customers require them, the company is also able to supplement this discipline with other support functions, including highlighting the environmental responsibilities that affect both workshops and wholesalers. This is a role that Ecobat Battery, through its associated group companies, can provide further practical help with, through scrap battery collection and recycling.

Underpinning the Ecobat Battery sales team is a 13-stong national branch network across the UK and Ireland, which means that as well as outstanding knowledge and service, customers also benefit from excellent availability of the industry’s most prominent brands.