DENSO highlights evolution of the ignition coil

In 1996, DENSO developed the car industry’s first, compact stick type ignition coil, which is currently the most common ignition coil seen in the aftermarket, but the story of ignition coils started long before then, as DENSO Pan European Strategic Marketing Manager, Fatiha Laauich, reveals.

In today’s low emission and high-efficiency engines, the key to effective combustion is consistent, high-energy ignition output. The high voltage required for this ignition, generally between 10 and 40kVs is provided by the ignition coil, which is a type of transformer that features primary and secondary coils of wire wrapped in layers around an iron core.

The role of the ignition coil is to transform the nominal 12V in a car’s battery into the thousands of volts that are required by the spark plug to generate the sparks needed to ignite the air and fuel mixture inside the combustion chamber, but where did it begin?

Introducing the Kettering system

Although ignition systems have certainly evolved over time, particularly as they incorporate evermore electronics, they still bear the hallmarks of the original coil ignition systems that were introduced more than 100 years ago.

The first coil based ignition system is credited to American inventor, Charles Kettering (below), who developed it for a major VM in 1910, by devising an electrical system that powered the starter motor and ignition at the same time. The battery, a generator and a more complete vehicle electrical system provided a relatively stable electrical supply to the ignition coil. Amazingly, this became virtually the only type of ignition system for petrol fuelled engines until electronically switched and controlled ignition systems started to replace mechanical systems, during the 1970s and 1980s.

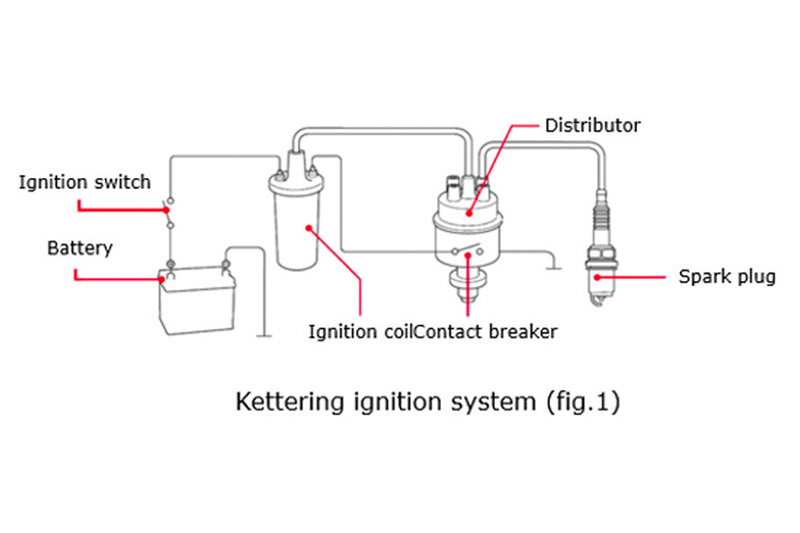

The Kettering system used a single ignition coil to produce a high voltage, which was passed to a rotor arm that effectively pointed the voltage to a series of electrical contacts located in the distributor assembly – one contact for each cylinder – and then connected to the spark plugs with wires in a sequence that made it possible to distribute the high voltage, in the correct cylinder firing order.

Following the introduction of the first electronic ignition systems, another significant step came at the beginning of the ‘80s with the development of the ECU. With its arrival, instead of the high voltage for the spark being controlled by a mechanical rotation inside the distributor assembly, the ECU, using additional and more accurate engine operating information, such as crankshaft position and speed provided by various sensors, could dictate when this voltage should turn on or off.

Over time, demand for higher engine speeds and higher spark voltages resulted in the introduction of the distributor-less ignition system (DIS). This uses one ignition coil for each pair of cylinders and is completely controlled by the ECU, delivering high voltage directly from ignition coils fitted with an integrated igniter to the spark plugs.

Then, in the ‘90s, came single DIS and coil on plug (COP) ignition coils. These are directly mounted onto the spark plugs, followed by the single ignition stick coil, which is still the type that is used on most modern applications today.

DENSO champions OE quality

Although the quality of OE coils is very high, in common with many automotive components, over time they do deteriorate and must be replaced, but workshops considering fitting anything other than an OE quality replacement should consider the important role they play, as without a fully functioning coil, the engine would simply not perform correctly.

DENSO offers the aftermarket sector a range of OE quality ignition coils, which encompasses block, distributor, stick and COP types. It is, therefore, able to cater for the needs of many applications.