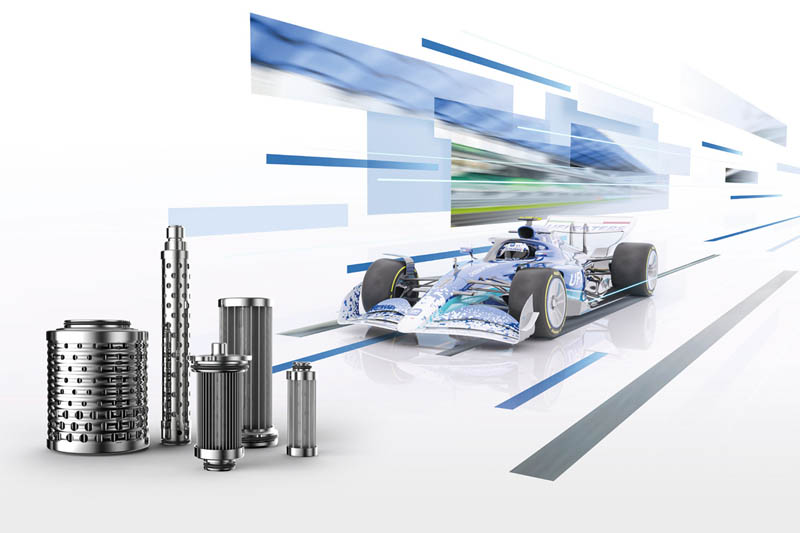

UFI supplies filters for Formula 1 teams

UFI Filters has cemented its position as a top producer of filtration systems by supplying nine of the ten teams competing in the 2024 Formula 1 season, which started on 2nd March with the Bahrain Grand Prix.

The announcement is said to be a recognition of the technologies developed by the High-Tech Division of UFI Filters, founded in 1999, and for the company, which has seen a series of successes in the motorsport’s top category since 1978.

In Formula 1, UFI Filters does not limit itself to providing teams with oil, air and petrol filters. The complexity of today’s racing cars also demands up to fifteen filter elements in a car. In total, UFI claims to produce around 8,000 such F1 filters annually.

Tailor-made solutions

For Formula 1, each filter is tailor-made for the needs of the different teams, with customised solutions provided in terms of size and materials used (which can include medical aluminium, carbon fibre and titanium). Their design requirements are the result of a co-design process between technicians in UFI Filters’ High-Tech Division and the individual racing teams. Often, during the course of the season, updates and modifications to the filters are said to also be requested by the teams, based on the developments gradually introduced in the cars.

The filters used for the cars can be subdivided, according to their location.

- Filters for combustion engines are located in the air intake, in the fuel supply and lubrication circuits. These are high-tech filters, which must not only trap dust and chips, but also any contaminants that may form in the special petrol used in Formula 1. The engine oil circuit also requires adequate protection: in addition to the main filter, there are secondary filter elements, and several ‘last chance filters’, which act on the recovery pumps.

- The filters in the hydraulic circuits play an essential role in driver safety. Their presence in the systems that preside over the hydrodrive, the activation of the mobile rear wing (the DRS) and the braking circuit are fundamental.

- The hybrid system with which the single-seaters are equipped, involves the presence of an energy-storage battery, the temperature of which must remain within an optimal range: dielectric fluids are used for its cooling, the filtration of which is reportedly guaranteed by UFI Filters.

Not just Formula 1

UFI Filters has accumulated a great deal of experience in motorsport, starting as early as the second half of the 1970s. Today, UFI Filters filtration systems are present not only in Formula 1, but also in other motorsport categories. In particular, in the World Endurance Championship (WEC) they are on board the Ferrari 499P, the winner of the Le Mans 24 Hours 2023, and the 296 GT3, as well as Lamborghini and Isotta Fraschini Hypercars. UFI Filters also supplies the heat exchanger for the front electric axle of the Isotta Fraschini Tipo 6 LMH, which is designed to increase the efficiency and reliability of the system. This is proof of the advanced technologies developed by UFI Filters, which not only claims to be a leader in filtration systems, but also plays a role in Thermal Management, an area of increasing importance due to relevance of e-axle temperature management.

UFI Filters is apparently also used by all Formula 2 and American IndyCar single-seaters built by Dallara.

In motorcycling, the company says it supplies its products to MotoGP (for Aprilia and KTM), Moto 2, Moto 3 and Superbike.

Italian pride

Giorgio Girondi, Chairman of the UFI Filters Group recalled: “It was 1978 when UFI Filters won its first Grand Prix in Great Britain with Carlos Reutemann’s Ferrari 312 T3, inaugurating a long series of triumphs. Since then, through sacrifice, dedication and passion, we have been able to develop customised solutions for the needs of nine out of ten Formula 1 racing teams. In light of this, we are continuing towards our goal of winning all the teams within the next two seasons. This is a source of great pride for our company, which is increasingly perfecting the advanced technologies that will also characterise the important transition which the automotive industry is undergoing”.