Dayco’s National Sales Manager, Steve Carolan, provides an insight into the steps the company has taken to meet emissions standards.

One of the most powerful drivers of change is governmental legislation, and in few areas is that more evident than in the automotive industry, where legislation influences everything, from lighting to safety standards.

Understandably, activities that have an effect on the environment are particularly highly regulated, which is why one of the key areas that appears to be under almost continuous review is the level of exhaust emissions emitted by the internal combustion engines that are still used to power the majority of the world’s vehicles.

In order to minimise the environmental impact, VMs work alongside their manufacturing partners to design and integrate innovative solutions that reduce the level of emissions their internal combustion engines produce, as well as the amount of fuel they use. Thus, innovation is also the name of the game when it comes to mechanical products, such as drive belts, tensioners and pulleys.

BIO tech

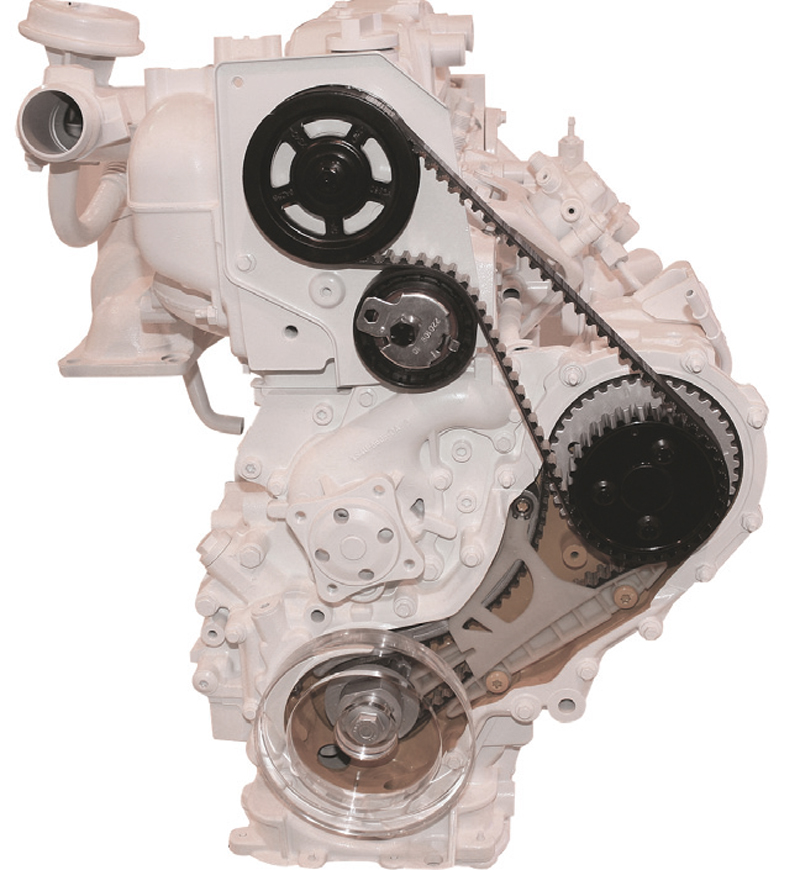

Belt-in-oil technology has brought together the best of belt and chain technologies. As a result of its implementation, the advantages of an external belt system have been demonstrated, with the weight of the transmission system and its inertia. This, combined with the lower friction properties of a flexible belt, delivers the twin environmental benefits of lower fuel consumption and reduced emissions.

However, perhaps the most significant contribution to these savings is the fact that, unlike a chain, a timing belt cannot stretch, which prevents the engine from undergoing phase variations due to elongation. Therefore, it actively helps to avoid increased pollution caused by incorrect valve timing. The technology also produces noticeably lower noise levels than a comparable chain driven system.

VMs are under enormous pressure to reduce exhaust emissions and increase fuel efficiency of the engines that power their vehicles, which means they need to push the technological boundaries in order to achieve the gains they need. Therefore, it is necessary for them to work in partnership with specialist component manufacturers to develop the technology needed to meet their objectives.

Ford has deployed a range of high performance, small capacity petrol and diesel engines to address the emission/consumption challenge.

The company’s EcoBoost family of turbocharged, direct injection petrol engines are designed to deliver levels of power and torque normally associated with larger capacity engines, while at the same time achieving 20% better fuel efficiency and 15% lower emissions.

Going green

Turning to the ‘green’ tensioner for 1.2, 1.6 and 2.0-litre VW diesel engines, Dayco designed a solution for reducing the force normally required on the auxiliary drive belt.

Naturally, a force needs to be allied to the belt to maintain its tension and prevent it from slipping, but also to keep it running smoothly and avoid any ‘backlash’ as the engine transfers between being under load when accelerating and over running when braking, for example. The greater the tension, the more power is sapped from the engine, so conversely, a reduction in the tension required provides direct efficiency gains.

A new accessory drive geometry and tensioner design that reduced the nominal tensioning force by 35% was developed by Dayco’s team, and this has resulted in a direct reduction of 0.5g/km CO₂ emissions for these engines.

Friction Wheel

One of the most interesting characteristics of the BMW-PSA 1.6-litre turbo petrol engine is the friction wheel that controls the water pump, which is activated only when the temperature of the engine needs to be controlled, and therefore allows the fastest possible warm-up, minimising emissions in the first phase of operation.

Dayco designed, developed and manufactured both the single-arm torsion bar tensioner that replaces the traditional spiral spring tensioner on the auxiliary drive system, and the motorised ‘switchable’ friction pulley that actuates the water pump.

At start-up, or whenever the engine is operating below its optimal temperature, the water pump is disengaged, which decreases the engine’s warm up time, reduces its overall emissions and improves fuel consumption. However, once the engine reaches a pre-determined temperature, the friction wheel is activated, and the water pump engaged, therefore allowing the engine to optimise its thermal management.

To prevent excessive acceleration forces on the bearing during off-on operations, the friction wheel is in constant contact with the back of the auxiliary belt that runs around the crankshaft pulley. With the use of an electric motor and small planetary reducer, the pulley’s radial movement is altered, and the rotating friction wheel comes into contact with the surface of the water pump pulley, bringing the water pump into operation.

Due to the confined space around these components, a traditional auxiliary belt tensioner could not be employed.

Aftermarket businesses need to be aware of this development because it is a very different solution to the traditional design they are generally familiar with. By being aware of the differences in the system, they will be able to implement the correct repair.

These OE developments are reflected in Dayco’s aftermarket programme, which allows factors to supply independent workshops with these solutions to enable them to offer their customers a like-for-like replacement that provides them with an alternative to the franchised dealer.