The automotive industry is in a period of unprecedented change; increasingly stringent regulations, evolving customer preferences, and the emergence of new technologies are shaping the future of the aftermarket, according to Simon Quantrell, deputy managing director of Carwood, a remanufacturer and technical services provider. Change is happening – and fast – but what about the here and now? Simon analyses the key trends and explains why the company is investing in both today’s and tomorrow’s technologies:

An electrified future

Driven by impending regulatory targets, more affordable costs, and improved battery technology and charging infrastructure, electric vehicles (EVs) are poised for significant growth. Indeed, 2021 saw record sales; according to the Society of Motor Manufacturers and Traders, more than 190,000 all-electric vehicles were registered last year, along with 114,000 plug-in hybrids and 147,000 hybrids, meaning that 27.5% of new car sales were electrified. This growth will continue to accelerate in the coming years, with all-electric vehicles forecast to account for 25% of UK new car sales by 2025, and 70% by 2030.

Plenty of mileage in the internal combustion engine (ICE)

Although EV uptake has been rapid, it’s important to remember that it’s starting from scratch. By the end of the decade, estimates suggest there will be around seven million EVs on the UK’s roads – just 20% of the total parc, which means 80% will be powered by some form of ICE, be it petrol, diesel or a hybrid. With the average age of a car at 9.4 years, even when the 2030 legislation change comes in, there will still be a significant parc of ICE vehicles – and for a long time. This will be much longer for commercial vehicles, where no other source can offer better emissions, range, affordability or usability than diesel.

Legislation driving improved technology

They just won’t be the engines you know today. Although modern diesels are already impressively clean, original equipment manufacturers (OEMs) will continue to enhance software and controls to meet even tougher Euro 7 targets. That same legislation has also paved the way for other greener, more fuel-efficient technologies, such as GDi – now the powertrain of choice for cars, when paired with turbochargers. They too are going electric and will become part of a hybrid set-up, generating boost, eliminating lag and recuperating spent energy.

Computers on wheels

These advances, along with the demand for more comfort, connectivity, and autonomy, has led to a proliferation of on-board electronics and software. A decade ago, only high-end cars contained 100 microprocessor-based ECUs, performing over 100 million lines of code. Yet, with features such as adaptive cruise control and emergency braking now standard, even regular cars are fast approaching that number. Premium models are half again, presenting an entirely new set of challenges.

To stick or twist?

With all these changes, the question is whether to focus on the now, the future or both? Since the Nissan Leaf became the first mass-produced EV, some 10 years ago, the leading manufacturers have all embraced electrification; however, with the exception of the likes of Tesla, none have put all their eggs in one basket, and most are continuing to develop their ICE offerings. As these vehicles filter into the independent network, you will need a supplier that can offer a broad range of current and future technologies, high-quality products and expert diagnostic and technical support.

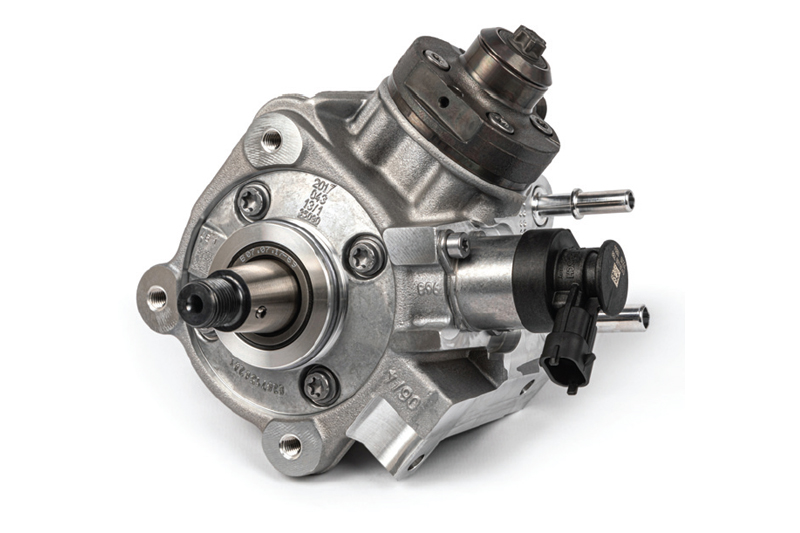

That’s why OE-approved remanufacturer, Carwood, is taking a hybrid approach of its own. We’re investing in both diesel, petrol, and hybrid and electric vehicle solutions; for example, we’re expanding our fuel systems business with a full Bosch programme for diesel and GDi, including OE new and eXchange units and repair components. Alongside our own remanufactured pumps and injectors, diagnostics, test equipment and technical support, you can access a full fuel solution from one supplier, saving time, money and hassle.

We are also continuing to add to our extensive turbo offering, with introductions geared towards the latest hybrid applications. With online cataloguing, next-day delivery and technical support, you can be confident that whatever vehicle comes through your customer’s doors, they will have the right part for the job.

In parallel, our specialist rewind business is developing a new range of remanufactured motors for hybrid and EVs. One of three main powertrain components, the latest generation of motors are much more complex, and many franchised and independent workshops are turning away the work. Planned for later this year, the new programme will provide aftermarket companies with another cost-effective, convenient and environmentally friendly service option to capitalise on.

Carwood is very much focused on the so-called old and new, refusing to switch allegiances. By bridging the gap, supporting both current and future technology, we are well-placed to grow with our customers.