Jeff Earl, Marketing Communications Manager at Schaeffler, discusses the company’s latest FAG steering and suspension offering.

At Schaeffler, we truly believe our FAG premium steering and suspension range offers a genuine quality alternative to aftermarket installers. Because of its many unique features and the reassurance of our technical support and customer service team, the range is an excellent choice for workshops.

Every single part has been designed to OE specifications, before being produced using the latest exacting material and manufacturing quality standards. All components come with a zinc-flake coating, wear and corrosion resistant clear TPU boots, and all the OE ancillaries needed to carry out a safe, long-lasting and professional repair.

Steering and suspension components are obviously safety critical, so quality should always be a major consideration for motor factors, as it’s vital that they supply their workshop customers with a product in which they have complete confidence to provide a solution that also gives the motorist peace-of-mind. In addressing these important criteria, the FAG steering range consistently delivers advanced quality standards and is backed up by Schaeffler’s REPXPERT workshop support system.

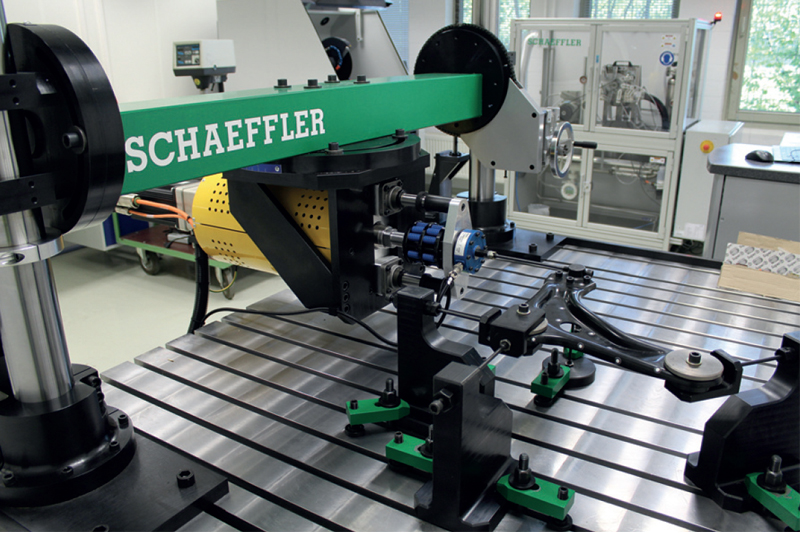

As a technical partner to leading vehicle manufacturers around the world, as well as an innovator with more than 130 years of chassis expertise, FAG has always had an uncompromising approach to quality. As a result, every single component in the range has been approved by Schaeffler’s own engineers, using the most stringent testing standards, right down to the last nut, bolt and washer. This unwavering attention to detail should inspire workshops to have complete confidence in the quality of every part.

An online appetite

When it comes to the response from the technicians responsible for fitting steering and suspension components, it was evident from Schaeffler’s first Zoom-based ‘Tea-break training’ session that the FAG steering range is one that they are keen to install. With this in mind, factors can provide a new and desirable range of products that will stimulate high demand.

Designed for all key applications in the European car parc, the market-oriented range naturally follows our philosophy of providing installers with a complete repair solution in just one box. This means that as well as being manufactured to the company’s OE quality standards, every box includes all the ancillary components needed to carry out a professional and safe repair, so there’s no need to hunt around for extras or to reuse worn parts.

The FAG chassis component range has been developed from the ground up to benefit from the company’s intelligent repair solution ethos, with Schaeffler’s product engineers demanding the highest material standards and manufacturing specifications to ensure consistent quality. Ball pins are nitride treated to maximize longevity, whilst all exterior surfaces have a zinc-flake coating technology to resist corrosion. They are further protected by clear thermoplastic polyurethane (TPU) boots with a micro-sealing lip design that adapts perfectly to the ball contour. As well as being unique to the UK market, they are also highly resistant to liquids and mechanical loading, whilst the transparent material allows the technician to see the quality and quantity of the OE specification grease inside the joint.

On the range, Schaeffler UK’s Managing Director, Nigel Morgan, had this to say: “Everything we do is geared towards helping professionals carry out the best possible repairs using the highest quality components. The FAG steering and suspension range naturally follows this ethos and allows us to supply factors with a brand that provides workshops with a viable alternative from a trusted supplier, along with the market leading support that comes with every Schaeffler product.”