As the vehicles become more technologically advanced, workshop equipment needs to follow suit. Traditional parts and tools are still a requirement, Draper Tools explains why it’s a good idea to ensure you’re well-stocked with new technology.

Whilst traditional repair jobs in the garage are by no means over, digital technology is undeniably playing a huge role in the maintenance of today’s cars, and this is only set to increase. Draper Tools claims to offer a wide range of high-tech electronic workshop equipment and service tools to help factors meet this demand. The company is offering some exciting new equipment that it hopes will appeal to customers looking to update their workshop.

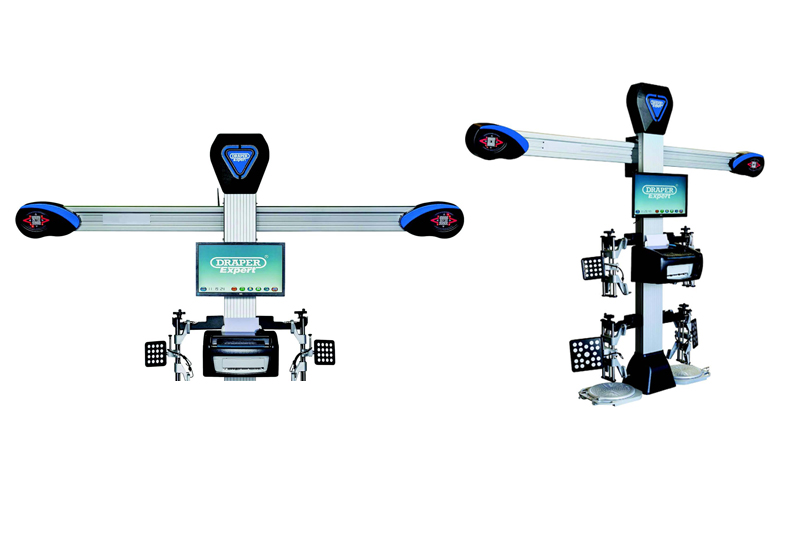

Draper Tools, which celebrates its centenary this year, has introduced new digital solutions such as the Digital 3D Four Wheel Aligner (01798), which uses high-resolution cameras to provide technicians with advanced alignment readings and chassis set-up information. It features a four-wheel system that gives increased accuracy to a multitude of suspension and steering requirements, which is essential for advanced vehicle stability systems.

The Wheel Aligner boasts a competitive price and user-friendly features. Its cloud-based technology and extensive vehicle database automatically compares the latest technical specifications with vehicle manufacturer’s recommendations. On top of this, it’s simple to operate, guiding technicians through the measuring process, which ensures that cars operate with maximum efficiency, comfort and safety. Plus, it offers free automatic system updates, free vehicle data updates and free technical assistance.

Workshop technology that makes life easier for technicians on the job is a top consideration too, with equipment such as the Draper Expert Semi-Automatic Tyre Changer (78612) also proving popular. It’s capable of removing and replacing tyres on wheels up to 26”, and is fitted with an assist arm (or ‘third arm’), which helps technicians that are faced with modern run-flat tyre technology and ultra-low-profile tyres. This piece of kit features a fully motorised turntable, pneumatically operated clamping jaws, powerful pneumatic bead breaker and tilt column to simplify the changing of low-profile and run-flat tyres quickly and easily, preventing damage to the alloy wheels.

Diagnostic tablets are another technology-led area where it’s advisable to have a strong offering for your customers. Look out for models that offer technicians value. The company highlights its Draper Expert Diagnostic & Electronic Service Tablet (12044), which has no lock out or catch up fees and comes with 12 months of free updates.

Vehicles these days are more than cars; they’re becoming smart devices, which in turn means that repair techniques are becoming more technologically advanced. Workshops face a challenge keeping up with these latest developments whilst balancing this with traditional skills and repair knowledge. Motor Factors can help their customers by having a strong, up-to-date offering in both areas, whether it’s the fundamentals like socket sets and jacks, or digital solutions for the workshop.