Effective engine management covers more than control of the ignition system and exhaust emissions. Thermal management requirements are sometimes overlooked, according to Nissens’ Marketing Manager, Jan Zieleskiewicz:

Nissens Automotive possesses decades of thermal management experience and has, therefore, developed a comprehensive engine cooling range alongside its AC portfolio, all of which are manufactured to Nissens’ ‘genuine quality’ standards, to allow you to supply independent workshops with premium grade replacement parts. These operate to the same performance levels as the original and so provides an aftermarket solution they can depend on.

So, returning to the theme of engine management, every vehicle powered by a combustion engine – and that therefore includes hybrids – needs effective thermal control of the engine, which means not only cooling to prevent overheating, but also means the quickest possible buildup in temperature to reach and then be maintained at the optimum level.

Naturally, the combustion process causes very high temperature ranges, exposing an engine’s block and its equipment to an extremely high thermal stress. Furthermore, turbocharged combustion systems also need sufficient air cooling to obtain the right charge performance. Manual gearboxes, as well as power transmission units, all need active engine management to ensure each component is operating at its design temperature to ensure the optimum performance of the whole powertrain.

To achieve these sometimes conflicting objectives increasingly requires electrical sensors, which itself reflects the growing number of electronically controlled components utilised in modern vehicle design. As a result, Nissens added engine coolant and oil temperature sensors to its range of thermal management solutions.

These introductions mirror the company’s ongoing focus on vehicle electrification and follows its launch of high voltage AC compressors, actuated turbochargers, EGR valves, fans, fan clutches, blowers and electric water pumps. Precise product identification, technical information, along with detailed drawings and complete pictures, as well as further information, such as sensor type, thread size and connection shape data, is easily accessible via Nissens’ online catalogue, which also contains imagery of each part.

Sensors “only part of the story”

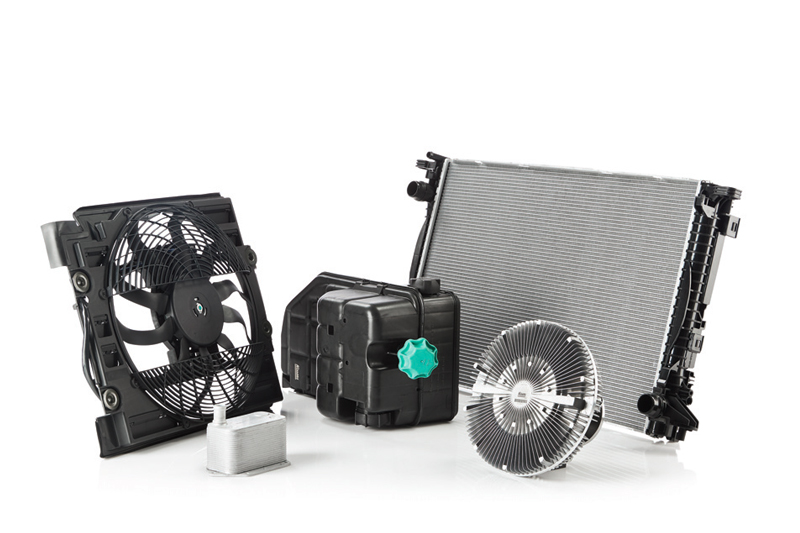

Components as diverse as radiators, oil coolers, fans, expansion tanks, water pumps and fans all play their part in the thermal control side of engine management, which is why, for the past nine decades, Nissens has been dedicated to deliver a comprehensive product range to the automotive engine cooling system.

The company’s technical knowhow, manufacturing experience and deep insight in thermal systems mean that it is flexible and able to meet the emerging market needs and can supply a wide range of premium quality engine cooling components.

In addition, the genuine Nissens quality standard ensures that the company’s broad product range delivers excellent durability and working performance, as well as trouble-free fitment. Nissens components are supplied with all the necessary installation parts whenever required by the original – for example, nuts, bolts, mounting clips and O-Rings etc – and are included in the box, which means that you can provide technicians with a Nissens ‘first fit’ solution.

Looking for efficiency?

The Nissens product portfolio of more than 4,500 parts covers everything from the fast moving to the more exotic brands from European, Asian and American VMs, with in excess of 17,700 OE numbers. These encompass radiators, intercoolers, cooling fans, water pumps, oil coolers, expansion tanks, fan clutches and, now, turbochargers.