Steve Carolan, Dayco’s UK National Sales Manager, explains how motor factors can make the most of the opportunities presented by thermal management.

As vehicle manufacturers (VMs) pursue the engine emission and fuel consumption reductions that have been imposed by worldwide legislation, every aspect of engine performance is minutely examined to ensure that all of its systems work in unison.

Central to this objective is effective thermal management, which is why VMs have developed innovative solutions or new concepts to ensure their engines not only reach their operating temperatures as quickly as possible, but are maintained at these optimal working levels.

Electric water pumps that can be activated instantaneously, alongside imaginative design solutions for mechanical pumps, therefore play an important part. These include those with vane shields, or even Dayco’s friction wheel, which can provide an instant response to coolant temperature changes.

Over the last few years, VMs have also moved to integrate the water pump into the primary drive (timing) system, rather than it being driven by the auxiliary belt. This has a direct effect on the aftermarket because, in contrast to the auxiliary belt – which rarely has a scheduled replacement interval – the timing belt does, meaning that technicians come into contact with the water pump more frequently than previously, and it is therefore far easier for them to assess its condition. As a consequence, more are found to be either in need of replacement, or are being changed as a ‘best practice’ precaution, so sales are on the rise.

In fact, over the last five years, the increase in sales of timing belt kits supplied with a water pump has increased significantly, which means that motor factors need to be aware and plan their stock accordingly.

Helpfully, power transmission manufacturers such as Dayco have proactively responded to this development by adding a water pump to their timing belt kits to provide factors and their customers with a complete aftermarket replacement solution.

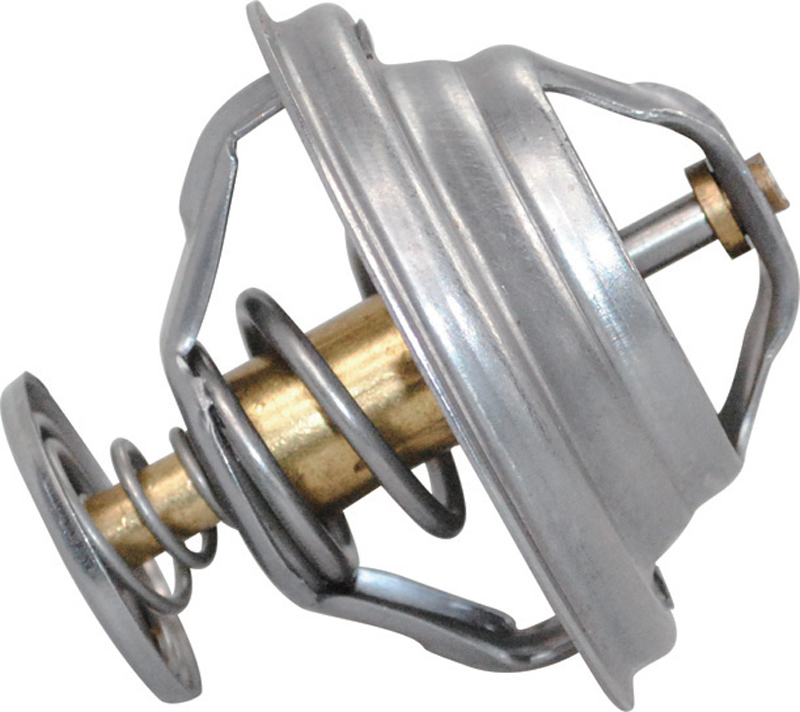

Designated by the KTBWP classification, each of Dayco’s water pump kits include the replacement pump alongside the belt, tensioner and idler combination, with 75 of these references containing the patented Dayco High Tenacity (HT) or ‘white’ belt. These sit alongside the company’s comprehensive thermostat range, which, together, provide independents with a complete, original equipment (OE) quality, thermal management solution.

Sometimes, for the best of intentions, workshops will try to save their customers money and replace only the belt and its ancillary components. However, this policy runs the risk of their customers having to face a much larger bill to virtually replicate the job if the water pump goes on to fail at a later date.

As a timing belt replacement is a relatively expensive, although extremely important scheduled service requirement, there is complete logic behind changing both the water pump and timing belt at the same time, as it is a far more cost-effective solution for motorists in the long run, and also gives the them confidence that their vehicle has benefitted from a full and thorough system overhaul.

Therefore, for the peace-of-mind of the owner, as well as the most profitable result for the workshop, Dayco recommends that technicians opt for a full timing drive system replacement, rather than just changing the water pump or timing belt in isolation.

As well as providing the replacement components that correctly reflect the developing technology of the vehicle parc, another benefit for a factor is that it gives them the ability to be able to supply a wider range of thermal management products from a single supplier.

OE derived components provide their customers with a number of tangible benefits from premium quality and fit first time installation, to increased durability and reduced warranty claims. In addition, however, when they fit an HT water pump/timing belt kit, Dayco can also provide factors, workshops and their customers with an even greater level of reassurance by offering the opportunity to extend the existing two-year warranty by a further year.

The Long Life +1 year warranty is a perfect example of how Dayco’s technology can provide workshops with a ‘real-world’ competitive advantage over those fitting other brands. It also gives the motorist a level of protection that cannot often be matched, even by the franchised dealer.

The combination of guaranteed OE quality products, which provide a wide-ranging thermal management offering, and product support such as the Long Life +1 year warranty, makes Dayco a great choice for forward-thinking motor factors.