PMF speaks to Matt King, Senior Technical Sales Representative at Clarios, the company behind the Varta brand, about Varta’s impact on the aftermarket.

Q. Talk us through your role at Clarios.

Matt King (MK): My day-to-day work is quite varied, sometimes working with our distribution partners and spending time with their staff in the branches, or at head office. Sometimes I’m visiting workshops, either independently or with the factors that supply them, and sometimes I’m delivering training or exhibiting at a trade event. Whatever the audience, I’m supporting on all battery related topics, and helping the branches and workshops understand the latest developments when it comes to modern battery replacements and the complexities that come with it.

Q. What recent aftermarket trends have affected batteries and battery technology within the automotive industry?

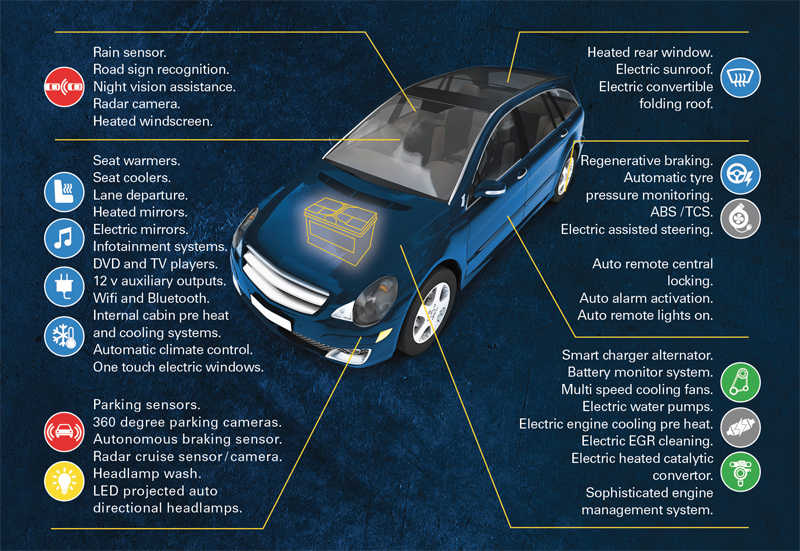

MK: What I’m seeing when talking to branch staff and technicians is, despite the fact that we have been talking about AGM and EFB batteries for a few years now, there is still some confusion when it comes to battery replacement. This isn’t surprising; we’ve had conventional lead acid batteries that have largely gone unchanged for decades, and now we have two newer lead acid types. As well as conventional, we have Absorbent Glass Mat (AGM) and Enhanced Flooded Batteries (EFB) for vehicles with start-stop systems and lots of electrical consumers.

Workshops are really starting to see lots of these types of vehicles coming in to aftermarket garages now, but they aren’t always certain which technology type might be required when it comes to battery replacement. It’s also harder to locate the battery on the vehicle, as they are sometimes in places that are difficult to reach, such as under a seat or under a cover in the boot. They can take over an hour to change, whereas traditionally, battery replacement took between five and ten minutes, and re-coding the battery to the Battery Management System is now the norm. These changes are adding complexity to battery replacement.

Q. How has Varta adapted to these changes?

MK: Varta offers a full range of conventional lead acid, EFB and AGM batteries, as well as auxiliary batteries to cater to all modern vehicles’ electrical requirements. 10% of start-stop vehicles also require a secondary battery, known as an auxiliary battery, and like all lead acid batteries, this has a lifespan and will at some stage need replacement. Varta offers a range of auxiliary types for those vehicles, and it’s not just niche vehicles either – many Volvo’s, BMW’s and Mercedes’ have a second battery.

In addition to the batteries, Varta also offers a range of support services to help with the aforementioned changes. For information on fitting instructions, battery location on the vehicle, and even fitting times per vehicle make and model, branch staff and workshops can sign up to the Varta Partner Portal. The portal tells users which battery to sell and fit to every vehicle, and also includes whether an auxiliary is required.

To access the Varta Partner Portal online, click here.

Q. How do Varta’s production processes set the company apart from other battery manufacturers?

MK: Varta is the number one battery supplier globally, with every one in three vehicles in the world being fit with a Varta battery. We have been making batteries for over 130 years. The company has 56 manufacturing, research and development facilities worldwide, and produces its batteries to the highest quality. Inside all Varta batteries, we have the patented Powerframe grid, the strongest and most efficient grid available – that’s what makes our batteries so reliable.

Q. With the aftermarket becoming increasingly environmentally conscious, has Varta taken steps to ensure that it is a responsible business?

MK: Varta is an example of the world’s best circular economy. Up to 99% of the materials in our batteries are recovered and recycled. New batteries are then remade using recycled raw materials. We recommend that all used lead acid batteries are collected and placed in recycling bins to ensure they make their way back to recycling centres.

Q. How would you say that motor factors could benefit from stocking Varta batteries?

MK: As Varta is a battery technology leader, and has a full range of batteries and support services, motor factors can be sure that they’re offering their customers the best products available, whilst also benefitting from technical advice from the company’s battery experts. In Europe today, eight out of 10 newly manufactured vehicles that have a start-stop system powered by an AGM come with a Varta battery. Supplying Varta to your customers is offering a like-for-like replacement part.