Behr Hella Service explores the latest developments in air conditioning, including refrigerant trends and A/C system design.

Alongside the natural evolutionary developments of heating, ventilation and air conditioning (HVAC) systems in general, there is a revolutionary change taking place in the refrigerant used within the air conditioning circuit of the contemporary vehicle. Originally driven by environmental concerns, the advances made are having knock-on effects, which now also increase the functionality of the system to the benefit of the occupants, in terms of their comfort and safety.

Historically, the refrigerants used in the typical air conditioning system were artificially created synthetics and not particularly environmentally friendly. Refrigerant exposed to the atmosphere, whether in the event of an accident or through leakage, had significant global warming consequences. As a result, legislators classified it with a global warming potential (GWP) rating.

After 1991, the dichlorodifluoromethane then used and designated R12, had a GWP of 10,000. The reference value used as the basis for comparison is carbon dioxide (CO2), which has a GWP of one, as measured by the global warming effect on the environment that one kilogramme of CO2 has over a 100 year period from when it is released.

The standard improved significantly with the introduction of tetrafluoroethene (R134a) in 1991 as it had a reduced GWP of 1,400 and with the implementation of tetrafluoro propene (R1234yf) in 2016, things got even better – its GWP is only four. However, the ability to use CO2 (R744) as an air conditioning refrigerant in the automotive sector – a development brought into the mainstream in 2017 – has meant that the magic GWP figure of one has now become a reality, with the environmental benefits that entails.

Although from an aftermarket perspective, R1234yf will remain the most common refrigerant for the short to medium term, motor factors need to be conscious of the introduction of R744. They need to ensure they are not only supplying their customers with the correct refrigerant, but also the appropriate replacement parts, as the use of CO2 has had significant implications on the rest of the air conditioning system, which both parties must be aware of.

The primary differences to the previous systems are connected to the extremely high operating pressure that CO2 requires to be able to work as an air conditioning refrigerant, which is approximately 140 bar (2,030 psi) on the high pressure side and 93 bar (1,350 psi) on the low pressure side. This is around 10 times higher than the typical, non-CO2 system.

As a result, the air conditioning system needs to be more effectively sealed, not solely because of the high pressure, but also because CO2 molecules are smaller than those present in the formulation of synthetic refrigerants. In addition, due to its higher energy content, R744 requires a lower mass flow rate to attain the same refrigerating capacity as the other refrigerants, which means that as well as increasing the capability of the air conditioning systems, the advantage can be used to achieve a more compact unit design and to reduce the flow cross-sections.

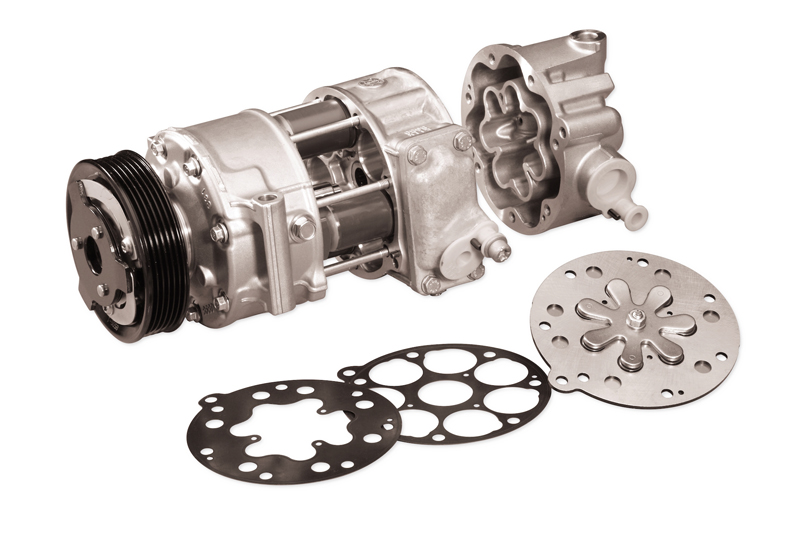

The components within the air conditioning system remain broadly similar to the previous incarnations, but with subtle adaptations to cater for the increased pressure, so it is imperative that motor factors accurately identify the replacement part required and technicians provide the correct specification when ordering the parts, as they are not interchangeable.

Apart from the use of a gas cooler in place of the now familiar condenser, perhaps the most obvious difference between the two systems comes with the refrigerant lines that are used to make its connections. In order to cope with the high temperatures, the lines on the hot gas side from the compressor to the gas cooler consist of a corrugated metallic pipe, held in shape by a steel-fibre reinforced tube, whereas the high and low pressure sides have no need for the additional reinforcement.

Both, however, incorporate special gaskets, which are designed to withstand the pressure within the circuit and to seal it against the atmosphere. They are connected with an interlocking device and the actual metal gasket that ensures an effective seal is located within it.

Technicians working on these air conditioning systems must be aware that the locking device, including the gasket, and the connecting screw, must be replaced whenever the refrigerant lines are repaired. This is necessary in order to ensure the maximum integrity of the refrigerant system.

When carrying out this work, technicians must pay close attention to cleanliness, make sure that the gasket is properly seated during installation, and that the sealing faces are oil and grease free, before installing the refrigerant lines.

Motor factors can be assured that Behr Hella Service has the necessary replacement components for these systems in its comprehensive product range.

“These air conditioning system developments provide Behr Hella Service customers with a tremendous opportunity,” explains Steve Hudson, the company’s Head of Business Development, “as it means they have the premium quality products necessary to repair these applications at their fingertips.

“In addition to these cutting-edge products, we naturally continue to increase our portfolio and offer the other parts they need on a daily basis, which is witnessed by the introduction of 55 premium products, as well as 40 mechanically/hydraulic driven cooling fans and components for the heavy-duty sector, plus an intercooler for the DAF XF-M EURO 6, in March alone.”