More and more vehicle manufacturers are incorporating double clutch technology into their vehicles, as they deliver optimum efficiency, combined with the comfortable and sporty drive their customers demand.

For motor factors, it is the clutch product of the future and a growth area that they need to be prepared for. They must also communicate that message to their customers, many of whom will have been approached about this type of work already; if not, they soon will do.

How does a double clutch work?

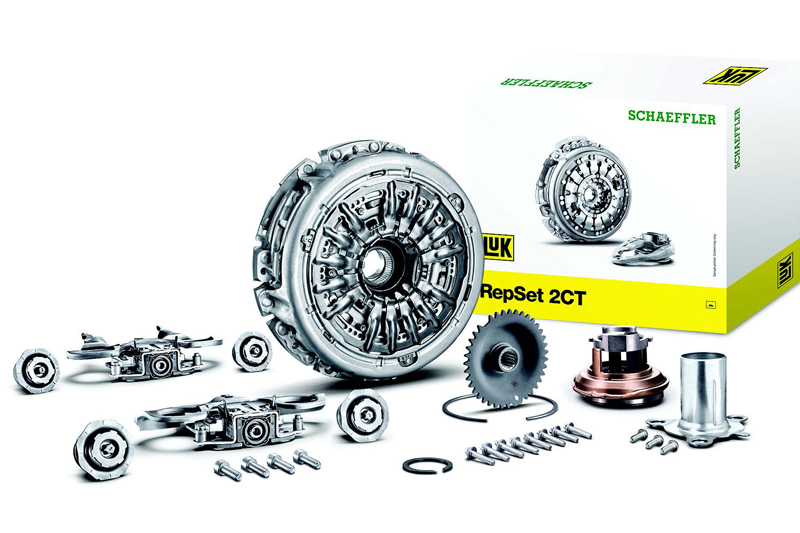

Like a standard clutch, a double clutch is a wearing part and one that will, at some point, require attention and replacing; however, unlike a standard clutch, a double clutch system is more complex. As the original equipment manufacturer (OEM), Schaeffler is ready to provide technicians with unique LuK 2CT RepSet 2CT repair solutions, corresponding special tools, IMIapproved training programmes and a range of installation guides and videos, via the REPXPERT website at www.repxpert.co.uk – or the recently launched app.

Schaeffler already boasts a range of LuK RepSet 2CT kits to service its OE dry double clutch systems and is also preparing solutions for LuK OE wet double clutch applications as well. In addition to a double clutch pack, the LuK 2CT kit contains all the necessary OE parts required to carry out a complete and professional repair.

In regards to the tooling, Schaeffler offers a special range that consists of a basic tool kit and several specific add-on modules, which allows technicians to pick and choose what is best for their workshop. It is a more economical solution for workshops that specialise in one or two marques. It is worth noting that virtually every double clutch system also features a dual mass flywheel, which can be checked and, if necessary, replaced far easier than on vehicles equipped with a single clutch.

Professional training

Proactive workshops should be preparing to stop sending these auto-shifting, yet manual clutch-equipped vehicles, to a transmission specialist, in order to access the increasing volumes of double clutch repairs and replacements that will come their way. To help them achieve this, Schaeffler has been holding IMI-approved LuK 2CT training courses at workshops and trade events.

The feedback from the training has been overwhelmingly positive, meaning technicians are ready and able to welcome the work, as well as carry out a thoroughly professional repair. Schaeffler recommends that motor factor staff advise their workshop customers about the double clutch evolution, as developing the skills of the technician will help to futureproof their business, as well as improve the relationship between distributor and workshop.