Despite the growth in electric drivetrains, the internal combustion engine is still the most common propulsion technology visiting workshops. In addition, with the pivotal role they continue to play in the powertrain of hybrid vehicles, they will remain at the centre for the independent sector for the foreseeable future.

Although many ICEs are powered by diesel, petrol is increasingly common, as it is the favoured fuel for most modern hybrids, so understanding spark plug technology and selecting the most appropriate reference for the application is as important as ever, according to DENSO, an OEM in spark plug technology.

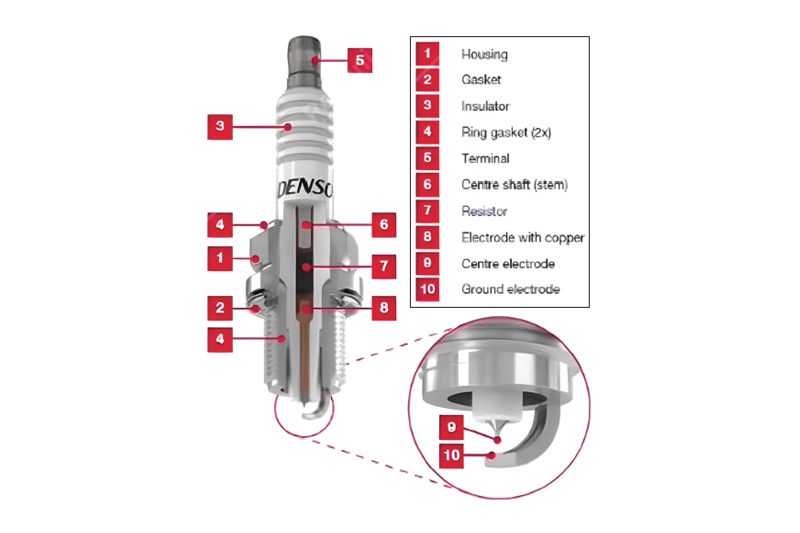

To be able to work effectively and efficiently under difficult operating conditions and to achieve the correct performance requirements, spark plugs are constructed in three main sections: the housing, insulator and electrodes, and these sections then contain individual components that are made from carefully selected materials.

The housing (1) forms an outer shell that surrounds and supports the insulator and secures the spark plug assembly to the engine. The ring washer or gasket (2) provides an insulating seal between the spark plug housing and engine to prevent any gases escaping during compression and combustion. The ground electrode (10) is mounted to the threaded lower section of the housing, which allows electric current to flow through the engine back to the battery.

The ceramic-based insulator (3) provides electrical insulation between the terminal, centre shaft, housing and centre electrode. With spark voltages on some modern ignition systems exceeding 40kV, the insulator, with a thickness of only millimetres, must provide the required insulating properties. As a result, DENSO spark plugs incorporate a ceramic material with high purity aluminium oxide to provide superior heat resistant characteristics, mechanical strength and excellent electrical insulation. The two ring gaskets (4) provide a secure fit and airtight seal between the housing and the insulator.

The high voltage is supplied through the terminal (5), either from a direct fit to the base of the ignition coil or by using a spark plug wire/cord that connects the plug terminal to the coil. Different terminal types are produced, which allows almost any high tension spark plug wire/cord or ignition coil to be connected to the spark plug terminal.

DENSO offers four different terminal types:

- Thread (with no terminal nut, used for motorcycles and older types of cars)

- Terminal nut (thread with nut that can be unscrewed)

- Crimped (thread with crimped nut for better connection between the nut and thread, but although the nut can be removed, it is more difficult)

- Solid (solid terminal for car applications, which cannot be removed)

The steel centre shaft (6) connects the terminal and the centre electrode, allowing high voltage current to flow from the terminal to the centre. The resistor (7), also referred to as a suppressor, reduces the peak current of the spark. Without a resistor, the peak current will create bursts of electromagnetic fields or radio noise, which can interfere with electrical equipment in the car. DENSO spark plug resistors are made of a special glass and copper powder mix.

The centre electrode (9) is made from materials, such as nickel alloys, that can resist high temperatures. These materials must also be extremely hard and durable to minimise the wear caused by spark erosion. The centre section of the electrode (8) often contains a copper core to improve thermal conductivity.

For improved performance and durability, centre electrodes can also be manufactured with an electrode tip made from precious metals that are even tougher than the traditional electrode materials. These harder wearing materials can operate at higher temperatures with reduced wear, but another major benefit is that they allow for the use of finer electrodes, resulting in better ignition performance.

DENSO spark plugs feature several unique patented materials:

- Standard 2.5mm diameter nickel alloy

- New and unique 1.5mm diameter nickel alloy (used in nickel TT spark plugs) that reduces spark wear by up to 40% compared to standard nickel

- Platinum, a precious metal that can withstand very high temperatures, with 1.1mm diameter electrodes

- High purity iridium alloy that is resistant to the highest temperatures and is the hardest material ever used in a spark plug, according to DENSO. These iridium tips with diameters of 0.4mm, 0.55mm or 0.7mm are laser welded to the centre electrode

DENSO reported these smaller electrodes lower the required voltage, ensure a reliable spark and reduce the quenching effect, so improving ignition performance.

The ground electrode (10) is subject to the extreme temperature changes inside the combustion chamber and although a nickel chrome alloy is used for most of these electrodes, platinum can be added to extend their life. Some spark plugs however, are equipped with a copper core ground electrode for improved thermal conductivity.

DENSO uses some features for the ground electrode to improve ignition performance:

- Patented U-groove, which increases the edge section, allowing sparks to occur easily and the flame to grow faster

- Taper cut ground electrode, shaped to reduce the quenching effect and improve flame growth

- Needle type with either 1.5mm diameter protruded nickel electrode (nickel TT) or a 0.7mm diameter welded platinum electrode (SIP and Iridium TT)

As with the centre electrode, the smaller needle type ground electrodes lower the required voltage, ensure a reliable spark, which reduces the quenching effect and improves ignition performance.