Why MOTs drive aftermarket demand

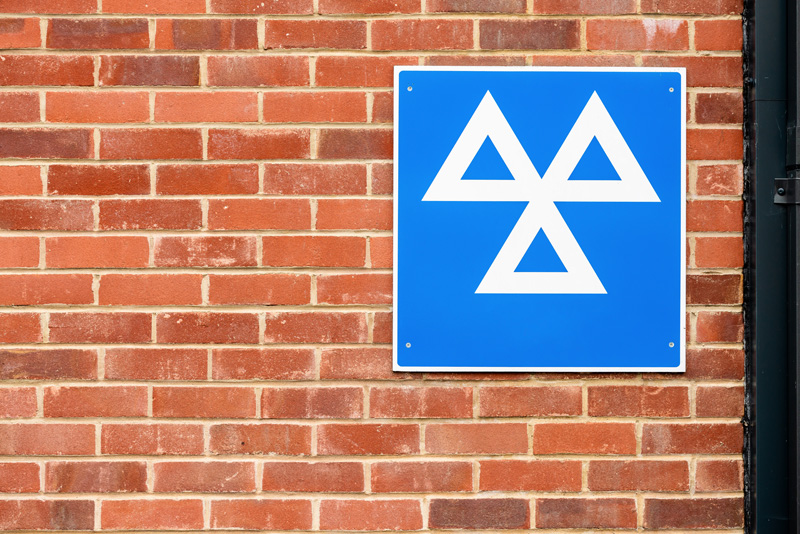

As environmental emission regulations have become increasingly rigorous, VMs have been refining the technologies to ensure the engines they design reach the required standards, but with the aftermarket, it’s primarily the annual MOT test that drives demand, according to DENSO Aftermarket Assistant Manager, Mike Sadler.

Although the engine management system (EMS) effectively monitors and, subsequently, controls aspects, such as the fuel, air and combustion process within an engine, many elements work to ensure it operates optimally.

Largely controlled through a series of sensors and actuators that communicate with the vehicle’s electronic control unit (ECU) to manage the process, these sensors monitor parameters, like engine speed, airflow, throttle position, coolant temperature and exhaust gases. The ECU matches them against a designated set of values and, if necessary, controls the actuators to ensure the correct levels are met, which, along with ignition components, ensures that fuel consumption and exhaust emissions are kept at their best.

If, however, engine faults develop that the actuators can’t adequately adjust, as well as triggering an engine warning light on the dashboard, the EMS stores them as fault codes that a technician can find using a diagnostic tool, which is often what brings the vehicle into the workshop; however, it’s the annual MOT that really drives emissions related product sales.

We recommend supplying OE-quality replacement components when faults cannot be repaired, as using lower-quality parts may lead to premature failure and the need for further replacements, ultimately increasing costs.

EGR system central to combustion

Due to their positive effect on the reduction of exhaust emissions, the EGR system is central to the modern combustion engine, as it is designed to influence the air-fuel (A/F) mixture formulation and, consequently, the combustion process. The idea is that by adding a larger proportion of inert gas to the A/F mixture, the combustion temperature is reduced.

Lower combustion temperatures result in a reduction of nitrogen oxide (NOX) in the exhaust gases.

The purpose of the EGR valve, which is often found to need replacing if emissions issues arise, is to recirculate some of the exhaust gas into the cylinder.

For efficient EGR, regulating valves are used in the intake air system, as they generate the pressure difference required between the exhaust gas side and intake side. As indicated earlier, after the A/F mixture has been burned, some of the exhaust gas is taken through the EGR valve. This regulates the subsequent mixing of the exhaust gas with the intake air.

This means that less oxygen reaches the cylinder, and less oxygen means a lower combustion temperature, which significantly reduces the quantity of NOX the engine produces. This is because the higher the temperature, the more harmful NOX is produced; therefore, the valve is a key component within the EGR system, as it regulates the quantity of exhaust gas that is returned.