Why Clarios is investing in European AGM production

Battery manufacturer, Clarios, has revealed it has invested approximately €200 million in its European plants and is expanding its production capacities for advanced adsorbent glass mat (AGM) vehicle batteries.

As of 2026, around 50% more units will be produced each year. In Europe, Middle East and Africa (EMEA), Clarios operates 13 production sites, including two recycling centres.

These investments are a part of Clarios’ strategy to invest globally in projects specifically focused on AGM production in the short-term, which allows Clarios in EMEA and its aftermarket brand, VARTA Automotive, to strengthen its hold in this region. Reportedly, the expansion is creating around 150 jobs in plants in Germany, Spain, Czech Republic and France, which, in turn, is enabling the building of ‘production clusters’.

Essential for sustainable mobility

Clarios acknowledges the automotive industry is changing, driven by the trends of electrification, digitalisation and circularity. As platforms become increasingly complex and power-hungry, Clarios believes there is a growing need for developing advanced low-voltage systems capable of providing the energy for performance and safety. It expects the global demand for advanced low-voltage systems will grow by 7% per year until 2030.

Clarios believes its AGM batteries are “essential” for sustainable mobility, citing “optimum performance” in EVs and in providing constant power for safety and comfort functions in both EVs and modern CVs. In vehicles with a combustion engine, these batteries enable fuel-saving functions, such as start-stop.

Clarios reports that its AGM batteries feature in seven out of 10 new vehicles with start-stop technology. Furthermore, Clarios adds that the xEV batteries for EVs, which were launched by VARTA Automotive last year, account for 90% of electrified vehicles on European roads and are also suitable for future models.

Focus on central Europe

The largest expansion of AGM capacity will be at the Hanover plant in Germany, which is also home to the European headquarters of Clarios. The company uses most of the investment to finance new assets, is optimising processes and shifting the entire site, including case production, to advanced battery technologies.

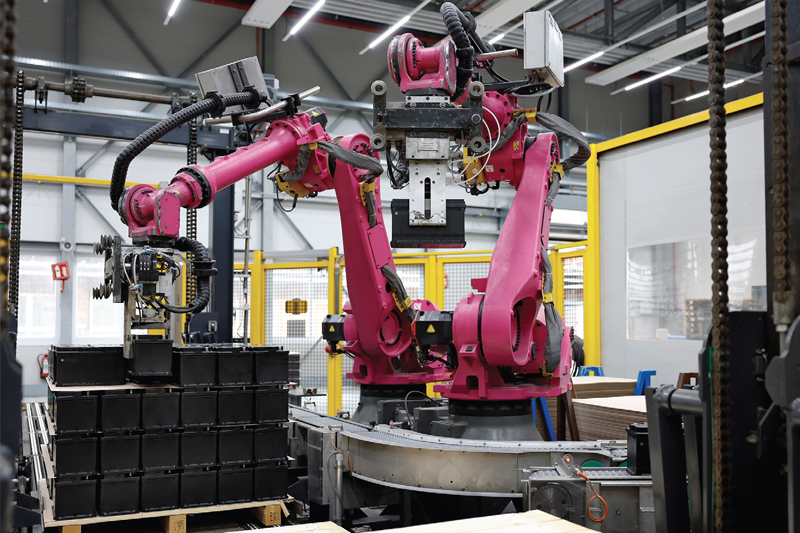

Clarios EMEA President, Dr. Werner Benade, said: “Through extensive automation, we are increasing productivity at the site and, at the same time, securing the existing jobs there.”

To create the necessary space, a significant part of the production of conventional batteries and the advanced EFB batteries for OEMs has been relocated from Hanover to Česká Lípa in the Czech Republic. Additionally, plastic housing for AGM batteries and small parts, such as plugs and handles, will also be increasingly produced in Česká Lípa.

In Zwickau, Germany, Clarios states it operates the largest production plant for AGM batteries worldwide. The annual capacity has increased, which is based on an investment volume of several million. Since the start of AGM production in 2002, more than 80 million batteries have been supplied from Zwickau.

The recycling operation in Krautscheid, Germany, supports the AGM expansion with increased recycling of lead alloys for the grids used in AGM batteries. The Krautscheid site, thus, complements the capacity expansion in the production network for Central Europe, which supplies to VMs in the region and in the aftermarket.

An additional production cluster is located on the Iberian Peninsula. In the future, conventional and EFB batteries for OEMs, which were previously manufactured in Hanover, will be produced at the Spanish sites in Burgos and in the battery case plant in Ibi. Production capacities will be expanded accordingly. To do so, equipment will be moved from Hanover and a significant investment will be made at the two Spanish sites. Clarios has already “invested heavily” in the Ibi plant over the past three years.

The production cluster on the Iberian Peninsula will also recycle lead from old batteries locally.

Dr Werner continued: “All these investments in our leading AGM technology ensure that our customers in the OEM and aftermarket business receive the best and most efficient batteries.

“We will continue to support all electric and safety-relevant functions for all vehicle types for a long time to come. We are pushing forward with our solutions for transforming the automotive industry by implementing the trends of electrification, digitalisation and circular economy.”