The importance of clean fuel

Modern engine technology demands precision — and fuel filtration is no exception. As engines become more sophisticated, their fuel systems are built with components engineered to tolerances of less than two microns and subjected to extreme pressures. This makes clean fuel essential, especially in diesel engines, where the fuel doubles as a lubricant for high-pressure pumps and injectors. Here’s Charles Figgins, product and technical information manager, for Blue Print.

Unfortunately, fuel purity can’t always be guaranteed. Contaminants from fuel station refills or corrosion inside metal tanks are common and pose serious risks. Even microscopic particles can damage injector pintles, distorting spray patterns and impacting combustion efficiency, fuel economy, idle stability and emissions.

Maintaining proper fuel flow is critical: while some contaminants may seem insignificant, poor filtration can result in restricted flow, reduced performance and long-term engine damage.

Why diesel needs more than just filtration.

While both petrol and diesel fuels require protection against abrasive contaminants, diesel engines face additional challenges. Water contamination is one of the most significant. Condensation within the tank, as well as water suspended or emulsified in diesel fuel, can lead to corrosion in sensitive fuel system components.

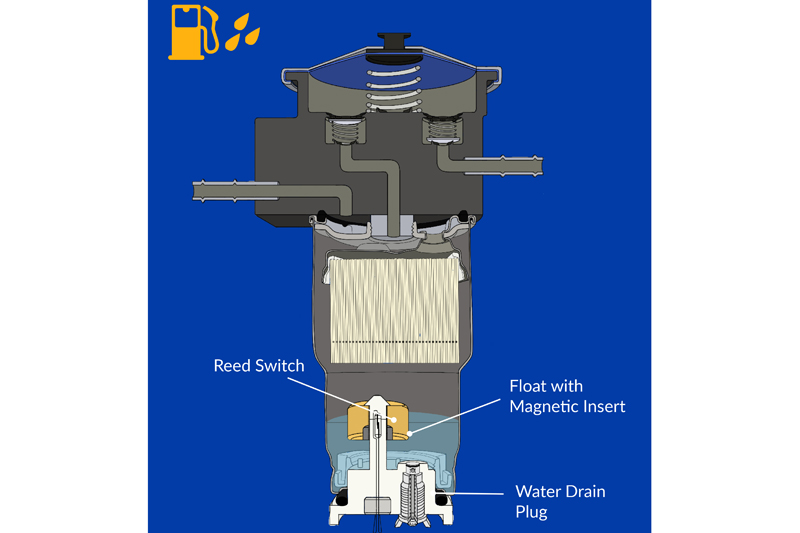

At Blue Print, our diesel fuel filters are engineered to address this issue directly. They utilise a hydrophobic coalescing material that allows fuel to pass through while trapping water. The separated water collects in the base of the filter canister and can be drained during regular maintenance — a vital step in protecting fuel system longevity.

The hidden risk: Microbial contamination.

Diesel is not only unstable, but it’s also organic — and this makes it an ideal breeding ground for certain fungi, such as Cladosporium resinae. Spores naturally present in the air can contaminate fuel, particularly in systems where diesel and water meet under warm conditions. Since many modern diesel systems continuously circulate and warm the fuel, the tank becomes an ideal environment for microbial growth.

The byproducts of fungal activity can clog fuel lines and degrade system performance. This is another reason why regular filter maintenance — and the use of high-quality filters that remove water effectively — is essential.

Blue Print: OE quality promise.

These petrol and diesel fuel filters are manufactured to meet or exceed OE specifications. This ensures proper fuel flow, maximum engine protection and long-term reliability. To reinforce this commitment to quality, we offer a three-year manufacturer guarantee on all replacement parts.