Delphi Technologies explains how it has made the selling and maintenance of its products as straightforward as possible, and how this will help factors to grow their business and develop lasting relationships with their customers.

The health of vehicle’s steering and suspension system determines its chassis dynamics, and is vital to how it performs. Although it may often go unnoticed, general wear and tear, and the fitting of non-OE parts as original components are replaced, can have a negative impact on the way a car drives. More importantly, it can affect durability and lead to reduced maintenance gaps, increased time off the road and rising costs of keeping older cars roadworthy.

Manufacturers invest millions into developing steering and suspension systems, carefully honing the setup to ensure that they’re more than the sum of their parts. Because of this, there are significant benefits to selling components that you know have been developed specifically to fit – and work – together.

“Steering and suspension systems are vastly complex and give cars their familiar traits, mannerisms and, of course, reliability; safety is ultimately the most important factor so to compromise in any of these areas is ill-advised,” Julian Goulding, UK & Eire Marketing Manager, Delphi Technologies, explains. “Lower quality parts don’t just wear out faster themselves, they can lead to accelerated wear of components around them, resulting in a false-economy. The adage ‘buy cheap, buy twice’ is often used, but it should really be ‘buy cheap, buy everything else’!”

Testing times

For Delphi Technologies, creating high- quality parts starts with meticulous testing and product validation processes, something lower-quality alternatives might not offer. The OE equivalent is analysed and reviewed, before 3D scanning and modelling systems collect data to the smallest details possible, and Delphi’s reengineering process can begin.

“The tests we conduct are designed to replicate the exact stresses they would be exposed to in real-world conditions,” says Goulding. “For example, a link stabilizer undergoes push-pull fatigue tests to replicate the forces the rod will experience on the road. Our test equipment completes thousands of cycles and tests the component until failure occurs.”

When testing a wishbone, Delphi Technologies tests all three axes at the same time to replicate side-to-side movement, forward force from acceleration and deceleration, and up-down movement.

“We could test the impact of these forces separately, but it would not accurately recreate real world conditions,” Goulding continues. “Therefore, our wishbones are comparable to an OE equivalent through their ability to withstand all three forces, and perform as the original part, something lower-quality alternatives may not be able to do.”

An expanded offering

This appreciation of a car’s chassis dynamics, says Goulding, has also led Delphi Technologies to expand its aftermarket steering portfolio to offer a full- service solution.

Steering components from Delphi Technologies contain all of the fitting accessories required by technicians. This ensures that there is no confusion over what may or may not be needed for each maintenance job, and reduces the chance of technicians walking away with incorrect parts.

“We want to make the lives of parts managers, factors and mechanics less stressful, and help to streamline the vehicle repair and maintenance process,” explains Goulding. “Of course, beyond the provision of physical parts, Delphi Technologies is also able to offer customers its wealth of experience to call upon, which hopefully helps educate the end-user and makes decision-making easier. Our technical hotline and support is dedicated to providing pragmatic answers to even the most demanding questions.”

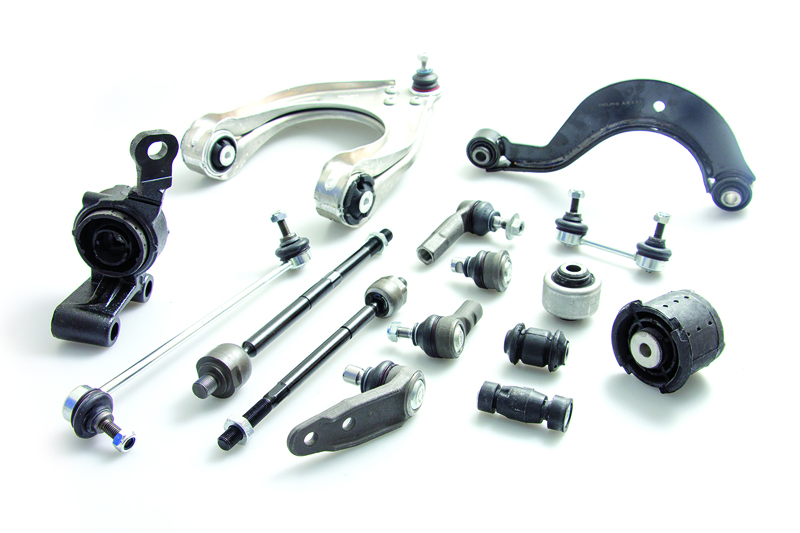

The company has introduced over 500 new steering parts to the aftermarket; spanning control arms, ball joints, link stabilisers and rod assemblies for Europe’s most popular models. Each aftermarket component is said to be manufactured to OE standards of performance and durability, and undergoes rigorous testing that covers material and dimensions checks, crack detection and fatigue analysis, and comes with a three-year, 36,000-mile warranty.

Promoting best practice

“The full-service solution is about more than just providing OE quality parts to the aftermarket, it’s about helping our customers to grow their businesses and help promote best practice,” concludes Goulding. “We want to help factors to not only understand how to install a part, but to increase awareness of any known difficulties and to provide the right accessories that are required to complete each job. Being able to provide technical insight will help factors to grow their business and develop lasting – and trusted – relationships with end users. So, as the aftermarket continues to proliferate, any additional support and simplification of these tasks is more than welcome.” concludes Goulding.