PMF gets the lowdown on Shaftec’s dedicated packaging area.

What is the first thing you think of when you cast your mind to the automotive aftermarket? Perhaps the latest technological advancements or the legislation that affects our industry might come to mind, but what about packaging? Whilst this subject may not set most of our worlds on fire, there’s actually a whole lot more that goes into the box that contains the component you just bought than you think. This is especially true when it protects something as valuable and delicate as a remanufactured EPS rack, for example.

The average remanufactured electric powered steering rack commonly costs hundreds of pounds, and when you factor in the surcharge on top of that, that’s quite an investment. This investment needs to be protected – quite literally.

It would therefore be completely counterproductive to package such parts in boxes made of flimsy, weak material. The boxed product not only has to find its way to the motor factor, but from there to the garage, and it may have to be stored in a warehouse before it gets to its final destination. That’s a lot of travelling, manhandling, and moving from one vehicle to another. And then at the end of its life, to protect the surcharge, it has to be returned in its original box or the integrity of the part could be seriously compromised.

Shaftec invests a substantial amount each year in R&D, and this investment includes looking closely at the design and manufacture of its boxes. The company works closely with its packaging suppliers, which utilise the latest technologies, material and processes at their global manufacturing facilities to ensure the optimal design is used for each product, and the most robust material make-up is utilised.

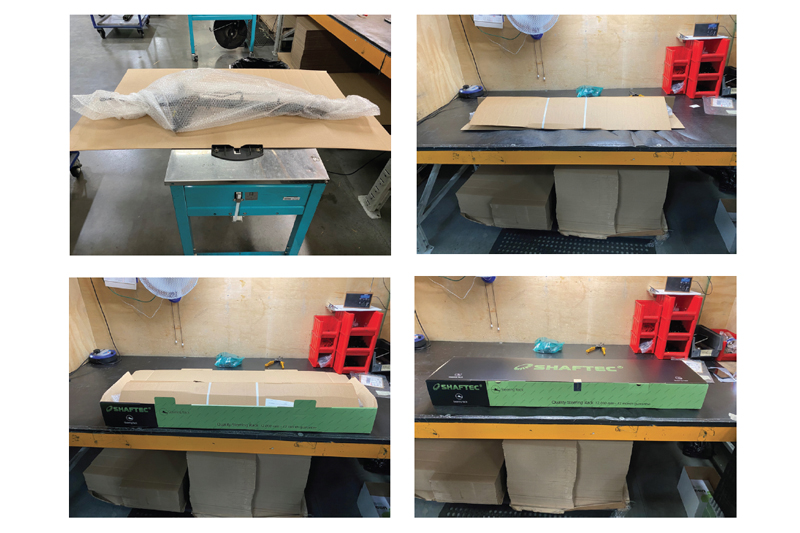

Once the EPS rack has undergone all of the relevant procedures, the product is transported to a dedicated packaging area at Shaftec’s 42,000ftÇ remanufacturing facility in Birmingham. These procedures include remanufacturing, being fitted with new ancillary parts, testing, and having any existing codes wiped to make it compatible with the next vehicle onto which it will be fitted. Added insurance comes in the form of tamper seals, which are placed on all electrical connectors so the customer knows that it has not been fitted previously since remanufacture, as this can cause catastrophic programming errors. And everything – from core acceptance, shot blasting and cleaning, through to piecemeal remanufacture and individual part testing – is carried out at the facility in Birmingham. Everything happens under one roof, allowing Shaftec to have much greater process and quality control.

When the EPS racks reach the dedicated packaging area, the delicate components are placed by hand carefully into boxes. The boxes for EPS racks contain a specially designed ‘cradle’, which holds the part in place, eliminating any movement during travel or handling to protect the fragile elements of the rack. The boxes are sealed with a hologram sticker.

Joe Toakley, Area Manager for the South at Shaftec, commented, “You’d be really surprised at how much work and effort goes into something which the end user doesn’t pay much attention to. Boxes don’t come cheap either, and when you are talking of packaging in huge quantities, this cost is significant.”

The packaging area also acts as a final quality control area where a last detailed check is carried out as the product enters the box. Any specific instructions or technical bulletins are also added at this point to ensure that nothing is forgotten and that when the part reaches its final destination, it can be quickly, easily and safely fitted to its intended vehicle.

It’s really important that the boxes are kept, as any old units considered for remanufacture must be returned in their original packaging to protect the surcharge and avoid rejection. This not only protects the actual fragile component itself, but it also allows for traceability. To top it off, at the end of its lifecycle, each box is fully recycled and forms the basis of the next.

So, there you have it, a look into Shaftec’s packaging processes from the perspective of the particularly delicate EPS rack.

Facts by number:

- 8: People that work in the packaging department

- 2,000: Boxes packaged each day

- 60,000m, or 60km: Metres of tape used annually.