Replacing receiver drier to protect AC system

The receiver drier is an important component of the AC system, according to Auto Air Gloucester Business Development Manager, Rachel Watts. This is because the part is used on vehicles that have a thermal expansion valve and captures moisture and debris from the refrigerant. It protects the compressor and ensures the AC works efficiently – Rachel dives into the details.

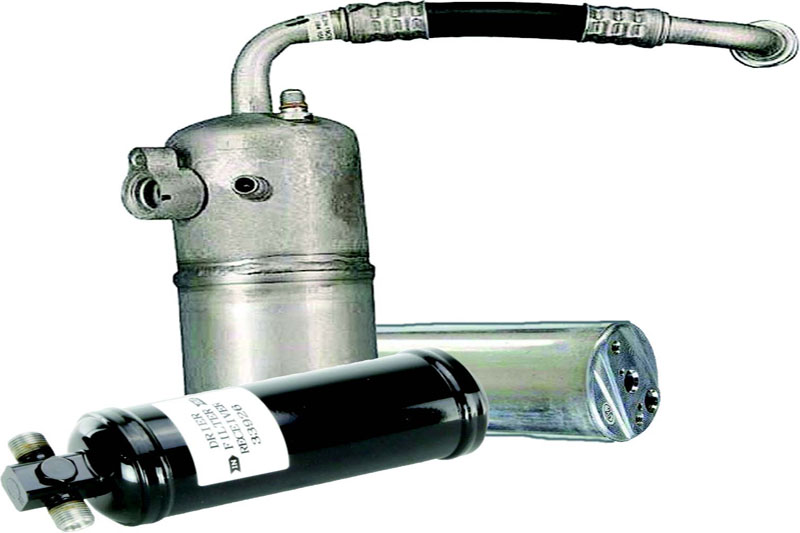

It can be found on the high side of the system, the side where the red hose of the charging station is attached. It’s located between the condenser outlet and expansion valve inlet. Usually bolted to the condenser, or it can form part of the subcooled condenser itself.

The drier acts as the filter. Its purpose is to retain moisture and contaminants in the system. Unwanted moisture will compromise the correct lubrication. Moisture can react with the refrigerant, leading to the formation of acids and other harmful substances. This can degrade the quality of the refrigerant and lead to reduced system efficiency. Unfiltered particles, freely allowed to circulate the system, can not only clog up the veins inside the condenser and evaporator, can block the expansion valve but, more costly, can cause the compressor to seize. By replacing the receiver drier, the technician helps prevent internal corrosion and extend the lifespan of the components.

The receiver drier contains a material called ‘desiccant’, similar to the small packets you might find in a shoebox or electronic device packaging. Desiccant has the ability to absorb moisture and water vapour from its surroundings. Over time, the desiccant can become saturated with moisture from the air. If not replaced, it can lead to blockages, incorrect pressure around the system and limit performance of components.

It is recommended that the receiver drier is replaced every time the system is opened for repair or at least every 24 months or 20,000 miles with an AC system service. The receiver drier cannot be flushed; it must be bypassed when a system flush is in progress and replaced, normally as the last part fitted, before vacuuming the system and regassing.

What can affect the operation of the drier?

Too much oil in the AC system will lessen the ability of the receiver drier to filter correctly. This is due to the desiccant beads and filter layer inside the drier becoming saturated. Excess UV dye can also have the same effect and destroy the drier.

Opening the AC system to the elements to change a component without changing the drier will have a detrimental effect. The desiccant inside will absorb moisture from the atmosphere. Once the system is closed, the moisture will remain trapped inside, eventually reacting with the refrigerant and oil to form a corrosive acid which will start to corrode the system from the inside out.

Flushing fluid left in the system will contaminate the drier and destroy the desiccant. To ensure this is not affected, always replace the drier when the system has been worked on.

The receiver drier is one of the cheapest components on the system, yet it is one component that rarely gets changed. After all, a technician wouldn’t carry out an engine oil change without changing the oil filter, nor should they leave an old drier on an AC system!

In summary, replacing the receiver drier in the AC system is a critical step in maintaining system performance, preventing damage and ensuring the longevity of the AC components. It’s a relatively small investment that can have a big impact on the overall reliability and efficiency of an AC system.