Remanufacturing in an ecological and economic way

AS-PL has made remanufacturing a strategic focus of its operations. This approach reflects the company’s commitment to ecological sustainability, strong supplier relationships and economic efficiency. AS-PL Marketing Manager, Jakub Rewiński, explores the key motivations behind this focus on remanufacturing.

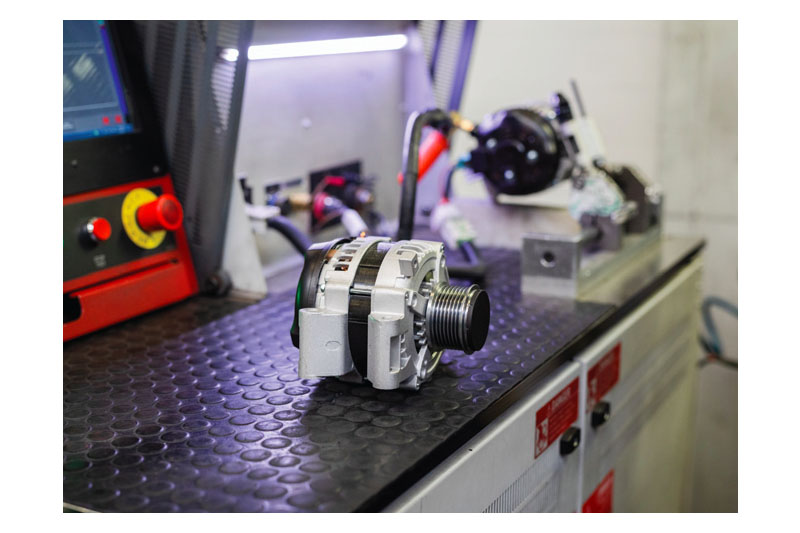

At our core, AS-PL’s remanufacturing philosophy is about maximising value while minimising waste. By giving alternators and starter motors a second life, we align ourselves with growing global demands for sustainability. The remanufacturing process, carried out at our production plant in Poland, involves reusing as many components as possible from existing parts, which significantly reduces the environmental impact of producing new components.

Instead of contributing to landfill waste, we ensure that more than 80% of the original parts in our Premium Line products are reused. The process also conserves resources, such as energy, water and valuable raw materials, emphasising our ecological responsibility.

Remanufacturing allows us to produce parts with performance on par with OEM equivalents, meeting the high expectations of our global customer base. This creates an appealing balance: providing environmentally friendly solutions without compromising on quality.

Relationship with core suppliers

The success of our remanufacturing efforts depends heavily on partnerships with core suppliers. These suppliers provide the essential used alternators and starters that form the foundation of the remanufacturing process.

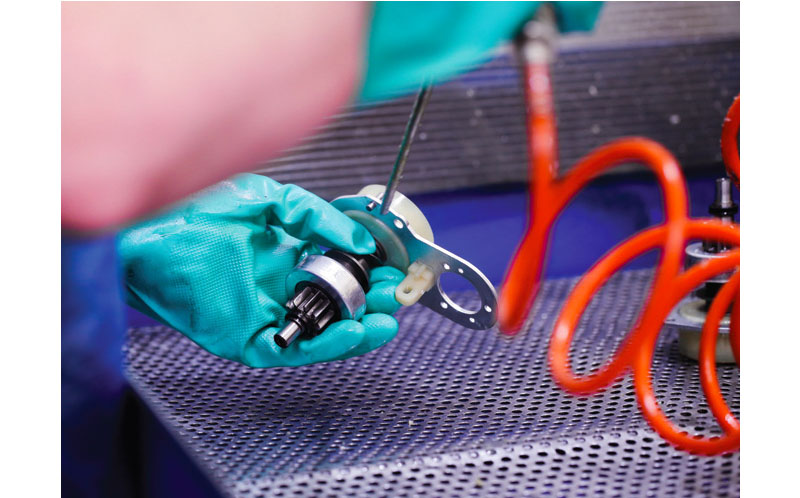

We work closely with specialised companies to source high-quality cores. Rigorous inspection and testing processes are applied to these cores upon arrival to determine their suitability for remanufacturing. Only cores that meet our standards proceed to the disassembly and refurbishment stages.

This collaboration with suppliers ensures a steady and reliable flow of materials, enabling us to maintain production schedules and deliver consistently high-quality remanufactured products. Such partnerships are built on trust and shared goals, creating a mutually beneficial ecosystem.

Cost and business benefits

The remanufacturing process offers a host of economic advantages for us here at ASPL, our suppliers and customers:

Cost-effective production: Reusing components reduces the need for raw materials and energy-intensive manufacturing processes. The products are a cost-effective alternative to buying new parts.

Improved efficiency: Initial testing of cores ensures that damaged or unusable components are eliminated early, reducing unnecessary strain on machinery and labour. This streamlined process boosts productivity and resource allocation.

Reliable products: Each remanufactured part undergoes rigorous testing, including final validation, ensuring that customers receive reliable, high-performing products. This strengthens our reputation for quality and may reduce warranty claims.

Global market reach: With operations spanning multiple countries and a vast product catalogue of more than 27,000 different products with a total of almost 720,000 reference numbers, we can cater to diverse markets.

Sustainability as a differentiator: Customers increasingly prioritise ecological solutions. Our commitment to remanufacturing aligns with this trend.

Our pursuit of remanufacturing is rooted in a vision of sustainability and operational excellence. By leveraging strategic relationships with core suppliers and optimising our processes, we reduce waste, save resources and deliver costeffective, reliable solutions to our dedicated customers.