In an increasingly environmentally conscious society, the role that Exhaust Gas Temperature Sensors play in keeping our vehicles healthy and in line with emissions standards cannot be underestimated.

In a global attempt to reduce our carbon footprint by decreasing our greenhouse gases, air pollution and fossil fuel usage, we are constantly pushing our vehicles to new heights with increased fuel economy standards and lower tailpipe emissions. These global emissions standards are continually changing and becoming more stringent each year. This, in turn, has created the need for smarter and more sophisticated exhaust after-treatment systems. At the centre of these aftertreatment systems are an array of sensors designed to monitor and control the different aspects of the vehicle’s performance and operating condition.

Included in this range of new sensors is the Exhaust Gas Temperature Sensor (EGTS), a commonly over-looked and ignored component. These sensors play a very important role in the overall health and performance of the vehicle and its exhaust system.

Generally, when we think of an EGTS, we tend to think that it’s only used on diesel powered vehicles. For the most part, this is true. High-temperature EGTSs were introduced on diesel vehicles in 2007, and it is estimated that there are currently more than 260,000,000 Sensors in Operation (SIO) around the globe today. On most vehicles, there are between three and six EGTS’s per vehicle. On newer vehicles using Gasoline Direct Injection (GDI), we will begin to see EGTSs being used on these more advanced exhaust aftertreatment systems.

The primary role of the EGTS is to read the temperature of the exhaust in multiple locations throughout the exhaust stream and send that temperature information to the engine control module (ECM). The ECM will then take this information and use it to control the exhaust after-treatment system to reduce harmful emissions and maximize vehicle performance and efficiency.

With multiple vehicle processes affected by the EGTS, it is crucial that they are performing within their limits. The systems affected include the Diesel Particulate Filter (DPF), Diesel Oxidation Catalyst (DOC) and Selective Catalyst Reduction (SCR) systems. The potential consequences for failing to replace an EGTS in a timely manner may include:

- A clogged DPF

- Improper regeneration of the DPF

- Replacement of the DPF

- Over-fuelling

- Increased exhaust temperatures

- Failure of internal engine components

- The appearance of the ‘Check engine’ light

- The vehicle is put into an idle only state, more commonly known as limp mode

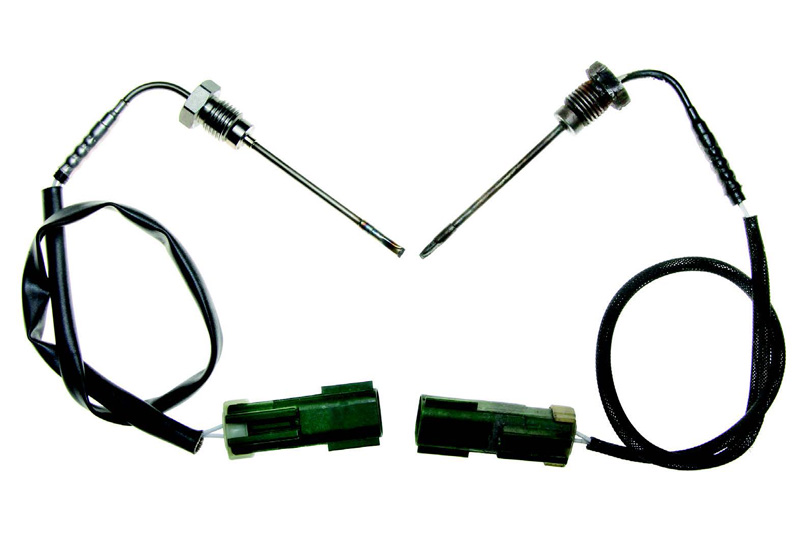

Not all EGTSs are created equal; there are many different types and styles of an EGTS. Some of these differences include: Closed and Open lower shields, Inconel and Stainless-Steel materials, Insertion depths and Fitment angles, Connectors, PTC and NTC Resistance types, and many temperature rating differences. The correct EGTS OEM base style sensor replacement is essential.

Walker Products offers a full line of aftermarket Exhaust Gas Temperature Sensors (EGTS), with over 300 SKUs, all being Euro 6 compliant. This provides the automotive aftermarket with the competitive program needed to service this technology trend, and combats premature failure caused by excess pollutants in the exhaust system as the vehicle ages.