Remanufacturing tends to be written about for the benefit of technicians. In the same way that it’s important for technicians to understand the nature of the parts that come into their workshops, it is essential for factors to know the full story behind the remanufactured components that they are selling. In response, Joe Toakley, Shaftec’s Area Sales Manager, discusses the physical process of remanufacturing a brake caliper.

With factors at the front line of the sales process, they are bound to find themselves being asked questions about what actually happens with remanufactured goods. These questions can include the following: What parts of the component are remanufactured, and what are new? What quality standards does the part have to meet? What tests does it go through before it ends up back in the supply chain?

Joe comments, “First of all, we need to be crystal clear about the benefits of remanufacturing. Remanufacturing is not a poorer substitute for new; it’s a process that results in the composition of components that are as good as new, tested as new, and perform in that way for the lifetime of the part. We need to dispel the myth that a remanufactured part is somehow inferior. It’s not. The only things on a brake caliper that are remanufactured are the casting, and sometimes the levers.

“Everything else is brand new, and the core is only remanufactured if it passes our stringent quality tests – namely that there are no cracks or weak points in the casting. Following the remanufacturing process, each caliper is tested beyond the OE specification. It is important to understand that, at Shaftec, we do not carry out batch testing. Every single component is tested individually – and this is the same for all of our remanufactured products, not just calipers.

“We believe in controlling as much of the process as we can. In line with this, everything – the sorting of the core, the remanufacture of the original casting, through to the reassembly using OE quality replacement parts and product testing, including pressure testing past normal working conditions – is all done under one roof. This gives us full accountability for our processes and ensures the highest level of quality control.”

Remanufacturing is an excellent compromise in terms of the environment, reducing emissions and energy use, and reusing existing materials. Remanufactured parts generally carry the same warranties as OEM parts, and VMs are becoming increasingly aware of the opportunities provided by remanufacturing to extend service life agreements and provide cost-effective solutions for older vehicles.

“Obtaining core in a fit state to remanufacture can be difficult,” Joe continued. “We are working with safety critical parts which need to be disassembled, reprocessed, rebuilt and tested. Damaged core isn’t suitable, and so we invest heavily in the quality of the return and the source of collection. The importance of core quality varies from product to product. When remanufacturing calipers, as long as the casting isn’t corroded or cracked, we can generally remanufacture them, as everything else is replaced using new, high quality hardware and perishable parts, and new motors in the case of Electric Parking Brake calipers (EPB).

“Prediction is a big part of the job of a remanufacturer, and forecasting reverse material flow can be problematic. We use bespoke formulas in order to forecast demand and production routines, and we have a team that concentrates solely on this, as well as sourcing core. Getting this right is a key ingredient for our processes to flow and to keep our availability as high as possible.

“To compensate for this, and to be as prepared as possible, we hold 50,000 caliper core units on-site that are awaiting remanufacturing, and we actively source rare and required core to keep our availability high.”

The process

1. The core enters. It’s checked against the reference using the bar code label on the box to ensure that it’s the correct part number. It is also checked for its suitability for remanufacture. If it passes, it goes into core reserves, ready to be remanufactured.

Joe commented, “Having the core returned in the Shaftec box is really important – firstly, our boxes are well made and robust, and will protect the core unit during transit. The label serves as a reference to what should be in that box. Without this, it takes much longer. The processes have to be stringent right from the word go.”

2. The caliper is degreased and thoroughly cleaned. Although Shaftec still performs some cleaning by hand, the company now predominantly uses a Technowash machine, which has significantly sped up the cleaning process.

3.The caliper is disassembled by hand to protect the delicate parts of the component.

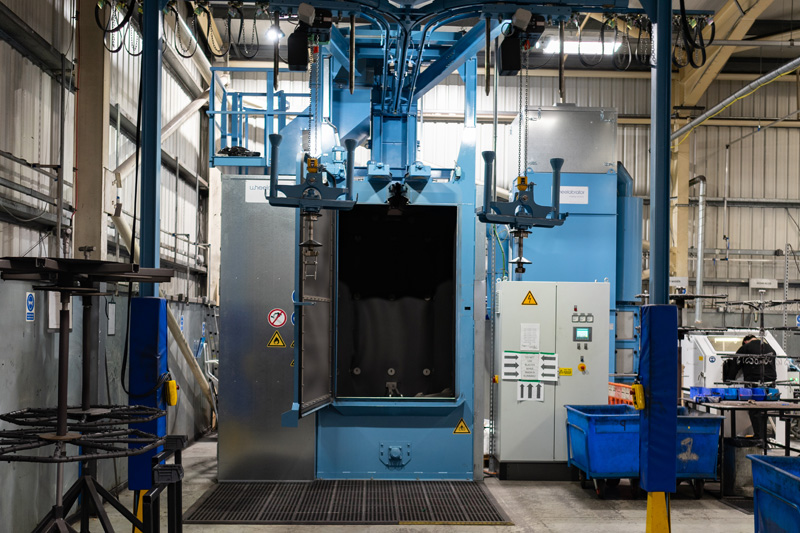

4. The caliper is shot blasted to remove any lingering debris. Historically, this was done by hand, however Shaftec’s new shot blasting rig has significantly increased production times. All calipers are individually inspected afterwards and finished off by hand if/where necessary.

5. The caliper is then inspected again before being painted.

6. The caliper is then assembled by hand. All accessories, such as the pistons and seals, are brand new. In fact, the seals are often over-engineered due to the improvements made since the original caliper was released. The only original piece is the casting, and if acceptable, the levers.

7. Every single caliper is then pressure tested individually.

8. The caliper is bagged in a sealed bag and placed on the shelf ready for dispatch.