Primalec’s Director, Richard Doran, discusses why new generation refrigerants need next generation lubricants.

R1234yf, the new automotive HFO refrigerant, has been with us since the start of 2011, when all newly Type Approved cars had to use an A/C refrigerant with a GWP below 150.

Since January 2017, all newly built vehicles have had to use R1234yf because there is no legally viable alternative. This new gas has allowed vehicle manufacturers to continue using most of the existing A/C components without major re-design, but R1234yf is less stable and more expensive than R134a, requires special compressor lubricants, and requires more careful servicing than its predecessors.

Added to that, A/C electric compressors, which need special lubricants with the correct dielectric properties, are increasingly common as more hybrids and plug-in electric vehicles join the road.

What is the A/C lubricant for?

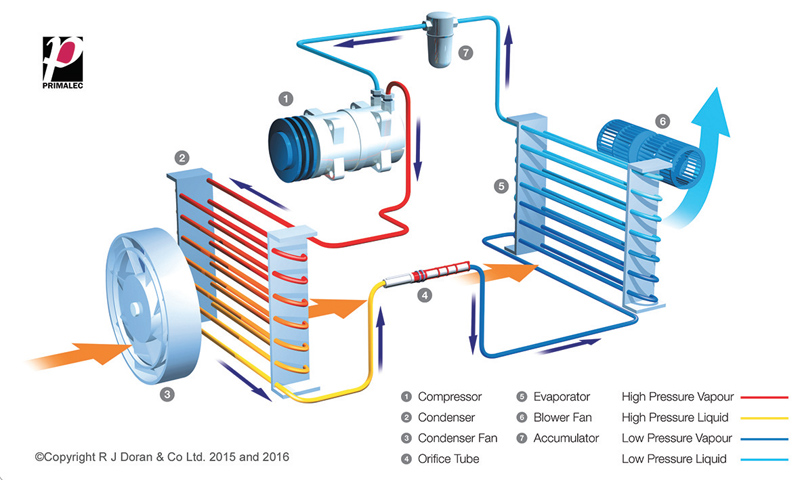

Its main job is, of course, to lubricate the moving parts of the refrigerant compressor, dissipate heat, seal the compression chambers and valves, and keep the seals and flexible pipes throughout the system in good condition, minimising leakage through elastomer degradation.

The oil shares its home with the refrigerant, so the two must be compatible and mix well together, as well as with all the different materials used in a mobile A/C system. Good miscibility lets the circulating refrigerant carry oil safely round the system to the o-rings, seals and flexible pipework, and back to lubricate the compressor.

Electric compressors add a further dimension in that refrigerant and oil come into contact with live electrical parts, so they need a lubricant with the correct dielectric profile. That is why it is so important to use the right oil for the job.

To make it easier and more profitable for motor factors, Primalec has teamed up with the world’s leading specialists in synthetic lubricant chemistry to provide a complete yet compact range of mobile A/C oils that can be trusted.

OEM-quality solutions?

Primalec’s Snow Leopard technical lubricants are made for the alternating hot and cold environments of A/C and refrigeration systems.

Formulated from select synthesised oils, refined with special additives to meet and exceed the needs of the compressor, Snow Leopard oils have the power and performance to lubricate and protect refrigerant compressors, and to optimise the performance of any A/C and refrigerant system.

HFO-PAG46e and HFO-PAG100e are the right oils to use in R1234yf systems when, as is most often the case, a PAG based lubricant is specified by VMs.

The Snow Leopard branded low moisture HFO-PAGs are now fully compatible with the electric compressors found in hybrids and plug-in EVs. They also give better lubricity and performance in all R134a systems than any ordinary R134a PAG oil. Their low hygroscopicity and exceptional viscosity index enhances compressor life by ensuring efficient running, even at high temperatures.

What this all means is that Snow Leopard HFO-PAGs can be considered as a genuine ‘one-type-fits-all’ solution, so when you choose these top-level lubricants, you escape the risk of using the wrong oil.

MRL85 is a polyolester (POE) based lubricant that has been engineered with an additive package that is better suited to R1234yf than standard POE oils. Some VMs specify a POE oil for their R134a hybrid and electric vehicles, and one or two have done so for R1234yf vehicles.

Being compatible with R1234yf, R134a and with electric compressors, MRL85 is an excellent choice for mobile A/C compressors when the vehicle manufacturer has specified a POE.