Ivor Searle examines engine remanufacturing

Ivor Searle Commercial Director, David Eszenyi, offers a comprehensive breakdown of the process of engine remanufacturing, the difference between reman and recondition, and why it has been a staple of the business since its inception more than seven decades ago.

The main advantage of sourcing remanufactured engines, turbos and gearboxes is the lower price point, with replacement major units from Ivor Searle costing around 40% less than a brand new OEM product. This helps to minimise the cost for end-users for what is typically a distress purchase and provides workshops with a competitive edge to support them in securing repair work.

Serving over 1,500 factor automotive distribution outlets across the UK and EU, our products are available off-the-shelf for next-day delivery on stocked items. Alongside a dedicated sales and customer service team, we have introduced a full e-commerce website, which enables you to gain quotes quickly and easily and place orders online. Featuring a VRN lookup facility, as well as search by vehicle make, model or engine code, the website also includes a host of information, including technical details and major unit installation instructions.

Quality remanufactured products also offer the benefit of full warranty protection; for example, our engines, cylinder heads and gearboxes are provided with a transferable 12-month unlimited mileage parts and labour warranty, while a two-year warranty covers all turbochargers. Expert support is also provided by our dedicated aftersales team based at our Soham headquarters.

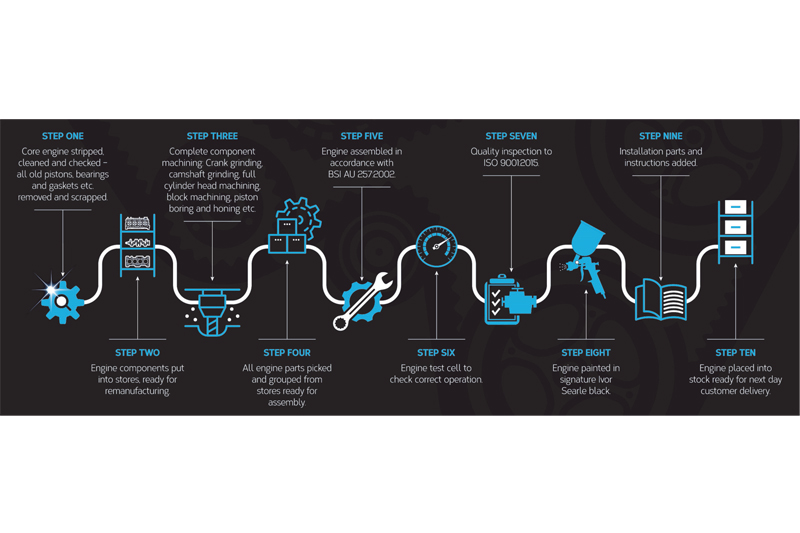

Engine remanufacturing process

Remanufacturing and reconditioning are sometimes used as equivalent terms where engines are concerned – but they are completely different. A reconditioned engine is a unit that has been fully stripped or partly disassembled, cleaned and may have had some damaged components replaced prior to being rebuilt.

In contrast, a remanufactured engine has been returned to the VM’s original factory specification. Furthermore, a remanufactured engine is required to meet a specific standard for it to be described as such under BSI AU 257:2002. This is a British Standard Automobile Series Code of Practice that applies to the remanufacturing of ICEs. The standard fully details the procedures and operations for the remanufacturing of both spark (petrol) and compression ignition (diesel) engines.

These processes include the detailed inspection and checking of components against manufacturer tolerances. Key parts, including pistons and ring sets, big and small end bearings and bushes, as well as gaskets, seals, timing chains and drive belts, are all required to be renewed, while items, such as tensioners and dampers, are also required to be inspected and replaced if necessary.

Further important operations, such as intensive cleaning, crack testing machined components and the deburring of reworked oil pathways, are also undertaken to ensure the original specification of the engine is achieved with full reliability. In addition to having all key clearances, tolerances and end floats checked after assembly, the standard also requires complete engines to be checked for oil pressure and compression.

Sustainability

Remanufactured units offer a sustainable solution compared to purchasing a brand new OEM product too, as considerably less energy and materials are used in the engine remanufacturing process; for example, our remanufactured engines conserve approximately 55kg in core metal, and around 85% of the engine’s original components are returned to OEM specification.

Ivor Searle: a background

Ivor Searle is an independent producer of remanufactured automotive major units. Established for more than 75 years, the family-owned business offers an all makes library of petrol and diesel engines, cylinder heads, gearboxes and turbochargers for cars and LCVs.

The company also provides a fast-turnaround DPF cleaning service that delivers “new levels of performance” by removing all soot and ash deposits. Covering around 90% of the UK’s vehicle parc, Ivor Searle’s products and services cater for all makes and models of car and LCVs. Based in Soham, Cambridgeshire, Ivor Searle employs over 100 people in three production facilities totalling over 70,000sqft.