How Nissens’ TM range helps ensure thermal comfort

Motorists should experience optimal thermal comfort not only during the initial days of spring and the hot summer months but throughout the entire year, according to Nissens Automotive. Here’s its marketing manager, Jan Zieleskiewicz, highlights the company’s thermal management (TM) offering in his latest column:

One of the critical elements of driver safety and comfort is the air conditioning (AC) system, and in vehicles with a permanent or plug-in electric drive, it is an important part of the vehicle’s overall thermal management (TM), which performs an essential role to enhance mobility.

TM ensures comfort in the cabin, regardless of the season, by heating or cooling the interior, but it also affects the proper function of the electric power drive, control electronics, and optimal battery operating conditions. So, regardless of the type of drive, it’s important to ensure the proper operation of the vehicle’s AC system through regular and professional service and the use of appropriate quality replacement parts.

To make the most of the opportunities that come with the climate season, you need to partner with knowledgeable suppliers, such as Nissens, to understand requirements and those of your workshop customers.

“Trust the experts”

To stay ahead of the competition and meet the demands of the independent service and repair sector, it is crucial to trust the experts and when choosing climate system service solutions, there are several factors to consider:

While the range, coverage, and availability of reliable quality parts are obvious, it is also essential to ease the strain on the technicians undertaking the work. So, assembly related features that make the replacement process safer and faster, and technical support from the manufacturer to help avoid common problems are priceless. All of this, along with a comprehensive parts programme, is made available through Nissens.

Nissens provides complete system component solutions and promotes sound education to prevent common service errors. Its TM parts offering is a comprehensive programme of nine key AC product lines, encompassing more than 3,680 items that provide excellent car parc coverage for all segments. As vehicle fleets develop and change, so does the range, which continuously expands to best match the most popular applications and address the recent technology evolutions.

Each spring, Nissens adds more than 250 new products to the programme, and the company continues its rapid growth of TM system parts for electric-driven car models. Among its most recent innovations are refrigerant pressure sensors and the high-voltage electric AC compressors for the most popular vehicle models, which have further expanded the climate parts range.

All Nissens’ components are manufactured to the ‘genuine Nissens quality standard’, which ensures performance, durability and easy installation, helped with additional items included in the (First Fit) set; for example, suitable O-rings, mounting screws, or the appropriate oil in the compressor are inside the product box. In addition, safe packaging and transport protection ensure that sensitive components arrive safely from the warehouse to the workshop.

Nissens also provides a wide range of technical support targeting industry specialists on various levels, and technicians can benefit from the use of its recognised quality training and technical support material. The portal, for example, includes a library of technical tips and service procedures, as well as tools, such as the oil and gas finder, with hundreds of vehicle makes and models, including the refrigerant and lubricant prescriptions for the newest and the most popular hybrid and electric-drive vehicle AC systems. The educational material in the programme also addresses the popular heat pump systems, widely applied in new energy vehicles.

Discover the difference

Almost all Nissens’ parts are designed with additional features, which improve their durability and secure optimal performance, and these include its condensers.

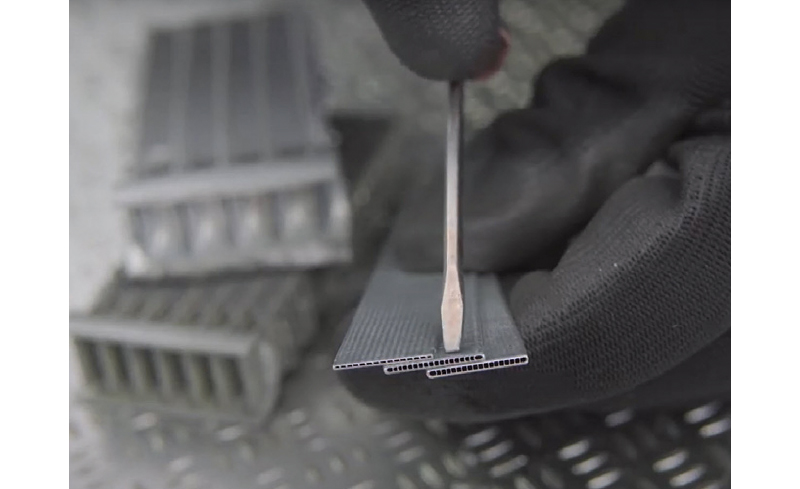

As the main heat exchanger, it plays a critical role in the efficiency of the AC system and the smooth operation of the compressor. Its frontal location in the vehicle exposes it to humidity, road-spread salt, and foreign objects thrown from the road, like stones, as well as insects and dirt. All these can quickly weaken the thin aluminium construction, leading to deterioration of its fins, thus significantly decreasing performance and ultimately leading to leaks and complete system and other component failure.

As a result, Nissens’ condensers are engineered to secure the product’s longevity. The solid, optimally designed size and number of tubes and fins, create a sturdy and durable, yet high performance, condenser construction. Before mass production of any new model, it is thoroughly tested in the company’s test centre, which utilises various validation methods, including a complete thermal performance test carried out in a wind tunnel. Thanks to the optimised aluminium brazing process, contamination of the heat exchanger surface has significantly been reduced, ensuring excellent airflow and, thus, optimal heat exchange.

However, the most crucial feature of a Nissens condenser is its anti-corrosive protection. The specially developed coating method enhances durability against chemical reactions and corrosion caused by moisture and salt across its entire surface. As a result, an advanced test series has proven that the lifespan of these coated condensers is significantly longer than that of non-coated OE and other aftermarket products.

Nissens’ condensers stand out, not only for their durability and performance, but also for their hassle-free and quick installation. This is attributed to their finish and fit, along with the inclusion of O-rings that streamline the refrigerant-tight assembly process. It is also worth noting that all Nissens’ condensers are pressurised with a neutral gas and, besides being solidly packaged for their transport, they feature tightly applied caps to protect the couplings from moisture and dirt ingression.