First Line explains how the push to reduce emissions has led to increased sales of turbocharger hoses, and how the company can cater to this rise in demand.

Legislative pressure on vehicle manufacturers to reduce exhaust emissions has led to the growing trend for forced induction engines, which in turn has led to an increase in the sale of replacement turbochargers. However, within the turbo system there are also several hoses that are vital to maintain the correct performance of the turbo unit, and subsequently, the engine’s emissions.

As turbo hoses are constantly exposed to changes in temperature and pressure, they are subject to abnormal levels of stress, which means that if they are not replaced when they show signs of wear, they will inevitably fail. So, when changing the turbo, technicians should automatically check the condition of not only the turbo hoses, but the engine’s other hoses as well.

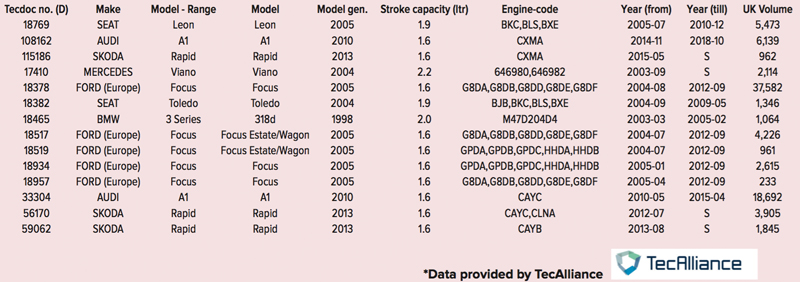

First Line’s range of turbo hoses offers more than 700 part numbers, to provide extensive coverage of the UK car parc. Amongst the most popular applications are the VAG A3, Leon, Golf V 1.9 TDI (part number FTH1078), Ford Focus 1.6 TDCI 2004> (FTH1295) and BMW E46 320D 1998-2005 (FTH1190). When it comes to recent new-to-range additions, the Audi A1 1.6 TDI 2010> and Skoda Rapid 1.6 TDI 2012> (FTH1543) are included, as well as the Mercedes Viano 2.2 and Vito 2.1 2003>16 (FTH1601).

In common with many aftermarket components, turbo hose identification can be quite a challenge, as technicians sometimes find it difficult to explain to a supplier which one is required. To help overcome this problem, First Line has created technical layout drawings for every application, so that customers can pinpoint exactly what they need. These can be accessed through the company’s WebCat and also be viewed in MAM AutoCat and TecDoc. Therefore, no matter what the method of identification used, technicians can quickly and easily find the correct turbo hose, reducing the need to source from the franchised dealer.

In keeping with the company’s practice, First Line turbo hoses are manufactured to the same specifications as the OE part. As the hoses operate at increased air pressures, reinforcement fibres are added to the walls of the hoses during their construction. These fibres help maintain strength and shape under these high- pressure conditions and are often polyester or aramid, dependent on the original specification. All these products are covered by a two-year/24,000-mile warranty.

Fixtures and fittings

Secure fitment is essential, so the company also offers 20 hose clips, available in both ‘standard’ 1000 series and ‘heavy duty’ 1100 series specification, to help technicians ensure they achieve the most effective seal.

Crankcase breather hoses

Crankcase ventilation is central to modern engine design. It helps to avoid the build-up of excess pressure and vents the by-products of engine combustion through the inlet manifold via a positive crankcase ventilation (PCV) valve. This regulates the evacuation of the gases and ensures the engine is running at optimum efficiency, thus reducing emissions.

However, the hoses from the crankcase to the PCV valve can get clogged with oil deposits and also turn brittle and split due to the constant heat cycles they have to endure – a process that is often accelerated by cold weather. Symptoms include poor idling, lack of power or responsiveness, oil fumes and oil leaks.

First Line offers a short six-part range of crankcase breather hoses to fit all BMW applications, which also benefit from the company’s two-year/24,000-mile warranty.