Hella’s Product and Brand Manager, Matthew Smart, explains the opportunities that an ageing car parc presents the aftermarket.

The coronavirus pandemic has accelerated the increase in the age of the average vehicle in the UK, as people have been both reluctant and restricted in their ability to purchase a new vehicle.

Being both unable, due to the prolonged first national lockdown, and unwilling to part with large sums of money in the face of employment uncertainty, UK motorists have held on to their existing vehicles as they wait to see what happens during 2021 and beyond.

However, as is often the way, what’s bad for VMs is good for the aftermarket; what tends to accompany an ageing car parc is the need to keep it running reliably and, in the case of increasing emission targets, ensure it’s able to conform with, and pass, higher MOT standards.

What particularly differentiates the ageing of the vehicle parc this time around is that there is a far greater requirement to keep vehicles running as efficiently as possible because of the increasing responsibilities that we have collectively towards the environment by reducing greenhouse emissions.

Government legislation has meant that there are higher standards that need to be met for a vehicle to pass its exhaust emissions test during the MOT, but motorists are also keen for their vehicle to provide them with the best return in terms of fuel economy.

Motor factors have a huge part to play in ensuring these standards are met because they can often influence the purchasing decisions of their workshop customers, so the onus is on them to ensure they supply replacement engine management parts of matching specifications to the OE components.

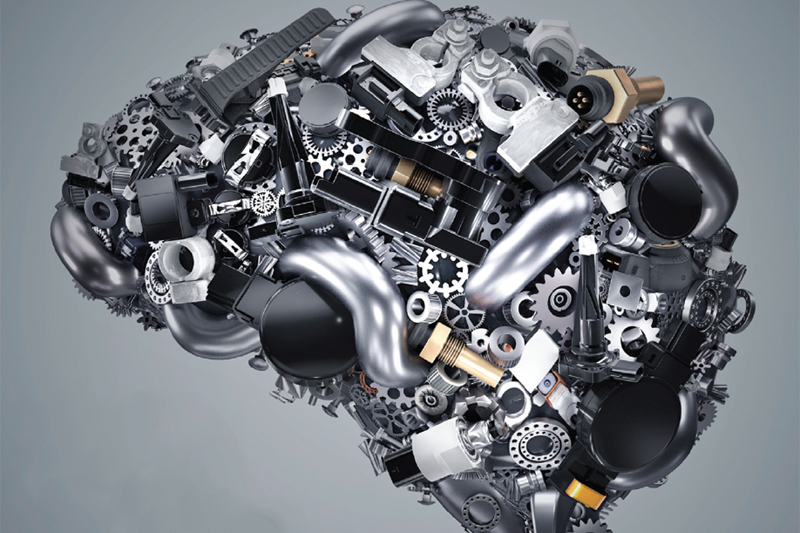

Naturally, the correct diagnosis of the reason why an engine management component needs to be replaced is vital at workshop level, but when it comes to supplying the replacement, suitability and conformity with OE performance standards should be the first concern.

Factors will clearly be familiar with the items that most regularly need to be replaced, which include air mass sensors and oxygen sensors, as well as exhaust gas pressure and temperature sensors, all of which play a key role individually, but also work together to ensure the engine is operating at its maximum efficiency and that emissions are kept to a minimum.

Taking in a wider perspective, the requirement for replacement air quality sensors is an opportunity that could easily be overlooked by factors. The purpose of an air quality sensor is to detect pollutants such as carbon monoxide and unburned hydrocarbons in the atmosphere, and better protect the vehicle’s occupants during their journey. It is mounted directly in the intake duct to the heating, ventilation and air conditioning (HVAC) system and, via changes in its conductivity, it communicates with the vehicle’s HVAC system via the electronic control units to regulate parameters such as temperature and blower fan speed, as well as to close the recirculation flap to prevent harmful gases entering the cabin.

Should an air quality sensor fail, the current industry perception is that replacements are only available from VM dealers. This, however, is not the case; Hella manufactures air quality sensors, and these feature in its existing aftermarket programme.

As this component is likely to become increasingly popular, we will be extending the range throughout the course of 2021, so we encourage factors to ask their workshop customers whether this is also an item they need whenever they receive an order for other HVAC-related parts.