Ecobat’s Marketing Manager, Laura Jones, highlights why Ecobat is the best option for factors looking for a battery supplier.

As an established business that has been trading in the UK for close to 70 years, Ecobat Battery Technologies’ ethos is to supply its valued wholesale customers with the high quality batteries they require, when they need them.

However, in addition to the products, it is also about providing an unrivalled level of customer service and support, which is only possible with the experience that comes from longstanding business relationships and a knowledgeable team with core battery expertise that is willing to go the extra mile.

By applying this ethos and working with factors with the same foresight that are willing to partner with us, we are able to not only grow their battery-related income, but build increased loyalty between them and their workshop customers, which provides even greater long term benefits across their entire businesses.

Naturally, it all starts with providing them with the products they need to support their workshop customers, and with Exide, Varta, Lucas and Numax, they have every option covered.

Interestingly, besides Ecobat being Europe’s largest specialist battery distributor, the all-encompassing Ecobat group is the world’s largest producer of lead and lead alloys, supplying battery manufacturers all over the world, including the brands it also distributes. As a result, annually, more than 50 million batteries are produced containing its lead and alloys.

In addition to the products, however, marketing support and design has long been an area that Ecobat has excelled in, allowing individual factors to tailor offers and promotions to aid their specific needs and ensure their workshop customers are equally well provided for.

Catering for the needs of workshop customers is also sometimes part of the brief, so joining forces with factors to raise awareness of the increasing number of start-stop equipped vehicles in the market, and running training events for technicians, for example, is another level of support that can be given.

These vehicles, all of which are fitted with either an absorbed glass mat (AGM) or enhanced flooded battery (EFB), are a growing part of the industry. However, there is still a surprisingly large number of workshops that are either unaware of the fact that these vehicles must use a specific type of battery technology or have – possibly due to fear of the unknown – yet to grasp the issue and are therefore also losing out on the potential it offers. Training events therefore help to overcome these problems.

However, it’s not possible to reach everyone via one-to-one training, so we have developed an online training and assessment programme to equip technicians to undertake this work with confidence, which will naturally bolster business at factor level.

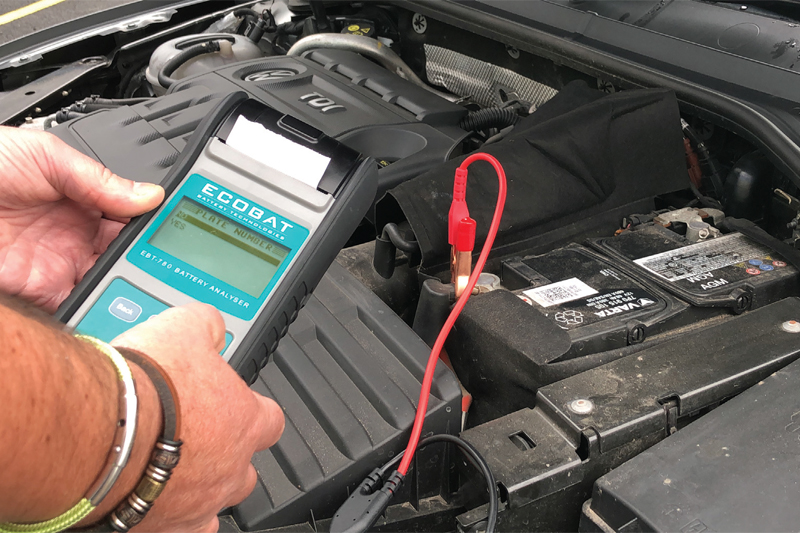

The package consists of a comprehensive training video which provides viewers with a step-by-step guide that takes them through the battery assessment, removal, replacement and validation processes.

Following the video, technicians undertake an online assessment that covers not just the removal and installation process, but information concerning the battery and the start-stop system, to discover whether they have achieved the necessary score to have passed. Successful applicants then download their certificate, which, once displayed in the workshop, provides motorists with a greater level of reassurance.

Environmental focus

Battery collection and recycling has never been more important as environmental concerns are high on the agenda globally. Through its battery collection services and facilities in Germany, France, Italy, Norway, Poland, as well as in the UK, the Ecobat group collects end-of-life batteries from all over Europe.

The processes followed ensure that more than 97% of the material is recovered from the battery during its recycling, which typically generates three main elements: lead, plastic and sulphuric acid.

The lead recovered through the smelting process is refined to produce various bespoke lead alloys, primarily for the battery industry. In Europe, up to 75% of the lead material consumed is derived from secondary recycling rather than primary production.

The recovered sulphuric acid can be processed to produce sodium or calcium sulphate, which can be used in a variety of applications, such as detergent, glass and textile manufacturing, and a wide range of industrial uses, from the construction industry to the food industry.

Plastics recovered from the recycling operations are further sorted, the most valuable being polypropylene from the battery case. This is processed and extruded to form plastic pellets. New battery cases and other automotive products are then produced from these pellets.

The final element of Ecobat’s comprehensive support package is to provide a fully compliant battery scrap collection service. All collections are then recycled through the group’s smelting facilities, which positions the company as a true ‘closed loop’ green supplier.