Discover Belt in Oil revenue opportunities

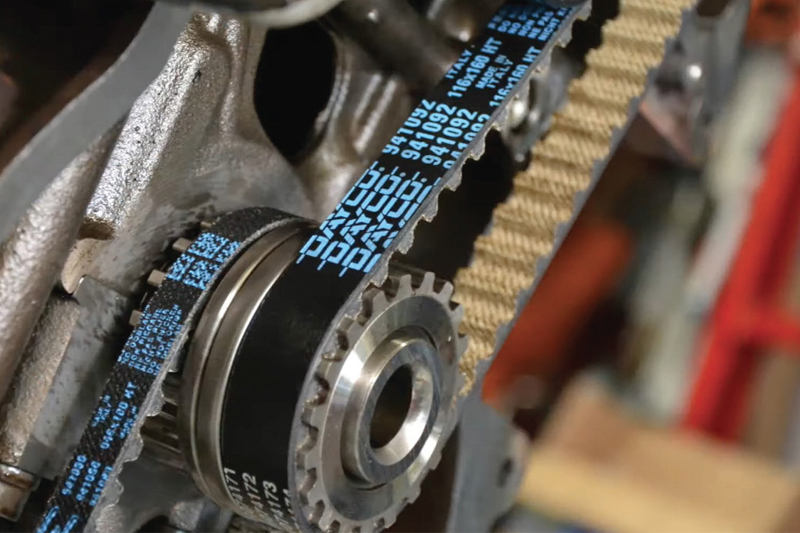

More vehicles now feature small-capacity engines designed to provide sufficient power while reducing emissions and improving fuel efficiency. To achieve these characteristics, many utilise a Belt in Oil (BIO) solution to drive the timing system, as the weight and friction reduction benefits play a significant role in achieving them. Dayco National Sales Manager, Steve Carolan, explores this practice further.

Dayco supplies OE components to VMs across Europe and pioneers BIO technology. Initially, it introduced BIO with the world’s first application in the Ford ‘Lynx’ engine, followed by the Ford 1.0L EcoBoost, PSA 1.2L PureTech, and Ford 2.0L EcoBlue engines.

All these units are now found in a wide variety of vehicle applications, making them frequent visitors to independent workshops; therefore, replacement BIO kits are a staple product for those servicing those workshops.

Although BIO technology is a fantastic solution that helps these small and efficient engines to deliver incredible levels of power, alongside exceptionally low emissions and excellent fuel economy, to maintain this level of performance and to continue to operate as the manufacturer designed, they need to be serviced regularly and the VMs’ scheduled replacement interval strictly followed.

This presents a significant revenue opportunity for the independent service and repair sector. To support technicians in delivering excellent service, Dayco offers OE replacement BIO kits for these engines as part of its extensive aftermarket line-up.

Tech tip

Although you don’t need to understand the minutiae of each installation process, it is worth stating that to further assist your workshop customers, and subsequently help to reduce unwanted returns/warranty claims, Dayco has produced another of its popular Technical Focus articles, this time on the Ford 2L EcoBlue engine used in many of the company’s vehicles, but perhaps most notably, in the Transit from 2016.

Reflecting the mileage these vehicles tend to cover and the sometimes unsympathetic conditions they are put through, it’s the Transit that is statistically more likely to require a scheduled timing system replacement. So, irrespective of which component requested, whenever you receive an enquiry from your workshop customers for a Transit part, it is best practice to mention that it is imperative that technicians check the condition of both the oil and the belt, every time one of these vehicles enters the workshop.

Following these checks, if any evidence of diesel or debris is found in the oil, and if there is any visible damage whatsoever to the back of the belt, then belt replacement is necessary because the failure of the belt will have catastrophic consequences to the engine.

No matter what the condition, however, Ford’s scheduled belt replacement interval must be taken as an absolute maximum, and that the oil pump belt is always also changed along with the timing belt. Dayco carries the timing belt kit (KBIO17), oil pump belt (941121) and auxiliary belts (6PK1410S and 3PK715) in its aftermarket range.

Although BIO systems are becoming the favoured primary drive solutions with several manufacturers, and so belt replacement increasingly common, there is an aspect of the EcoBlue application that it is worth you pointing out to a workshop undertaking the work – and that’s the timing belt cover. This is a relatively thin metal sheet, that will be damaged during its removal and is, therefore, not reusable. So, a replacement, along with the appropriate sealant, must also be sourced before the work is started, which is another astute revenue opportunity.