While there is no denying EV sales are growing, Dayco National Sales Manager, Steve Carolan, is urging industry professionals to not take their eye off the internal combustion engine (ICE):

It’s quite right that both workshops and motor factors keep their eyes on the future, so they are ready to adapt to the demands of their customers, but with the trade’s preoccupation for all things electric, it’s easy to overlook the fact that the vast majority of the vehicles that will enter the independent workshop for the next decade will have an ICE, whether petrol or diesel.

This assumption is drawn by looking at the complexion of the UK passenger car parc from publicly available data, which shows that over the last 12 years, it has grown from around 27 million to more than 32 million, while over the same period the average age of these vehicles has increased from 7.3 to 8.6 years. So, it’s reasonable to suggest that vehicles sold in 2021, the last full year that we have the figures, are likely to still be on the road in 2030.

Clearly, the increase in the sales of alternative fuel vehicles (AFVs) is on the rise, but of the 1,350,403 new car registrations in 2021 (a figure that, for simplicity, excludes the 296,778 mild hybrids, which would, incidentally, also utilise a combustion engine), 897,876 were either petrol or diesel – that’s almost 66.5%. Even with the addition of the 452,527 AFVs that make up the reminder of the year’s total, they still only represented 3% of the 32 million cars in the vehicle parc. In fact, the projections indicate that it is not until the mid 2030s that AFVs will achieve parity with ICE, and that by 2040, ICE will still be 40% of the total, which is likely to be approximately 13 million cars and similar to the current passenger car parc of Benelux!

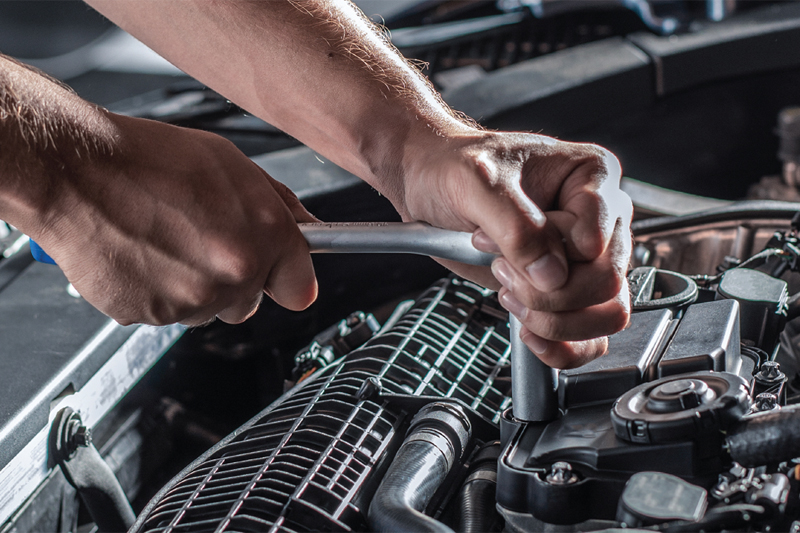

So, what do these figures mean for independent workshops and their motor factor supply partners? Well, it would be complacent to just say it’s ‘business as usual’, because as I mentioned earlier, it makes complete business sense to keep an eye on the developments in the market and take advantage of the opportunities they present; however, foregoing training and learning more about the best practice service and repair requirements of ICE powered vehicles, which are still becoming ever more complicated, in favour of AFV technology, doesn’t seem a wise decision, while ICE is, and still is likely to be for the next decade, the main revenue source for the typical workshop.

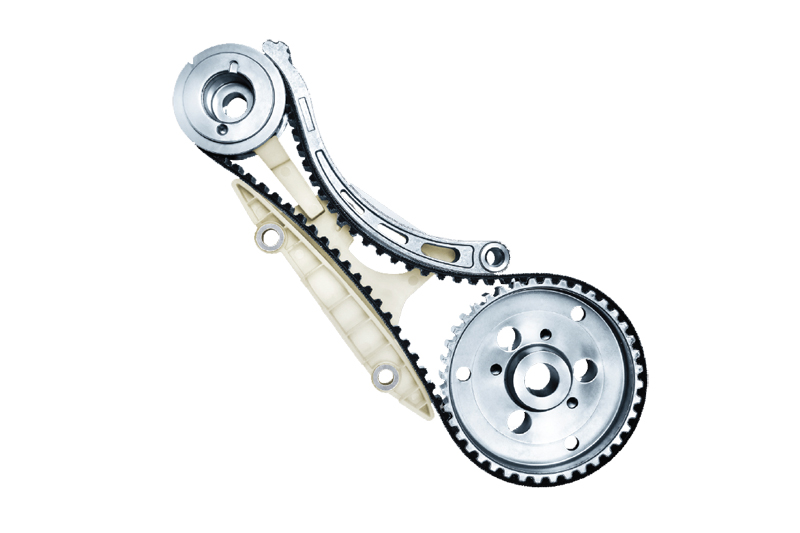

Addressing the topic of developing ICE technology, if you look just at a single product sector, power transmission and timing drive systems specifically, there is still a lot that many technicians can learn and revenue that workshops can benefit from.

Belt in oil (BIO) systems are a perfect example, as the concept will be around for the long term, which is demonstrated by the fact that the 2.0l TDCi engine used in models, such as the Ford Transit, is planned to be in production until 2030, so the newest vehicles are unlikely to enter the aftermarket until 2033.

Therefore, workshops servicing and repairing vehicles with BIO systems must have technicians that are fully aware of the potential problems that can arise with them, what issues they need to look out for and are proficient and knowledgeable in the specifics of their correct replacement, and that requires an investment in training. It will, however, also unlock a reliable revenue stream for the long-term benefit of the business, and I might add, the motor factor supplying the replacement kit!