Dayco insists BIO technology benefits aftermarket

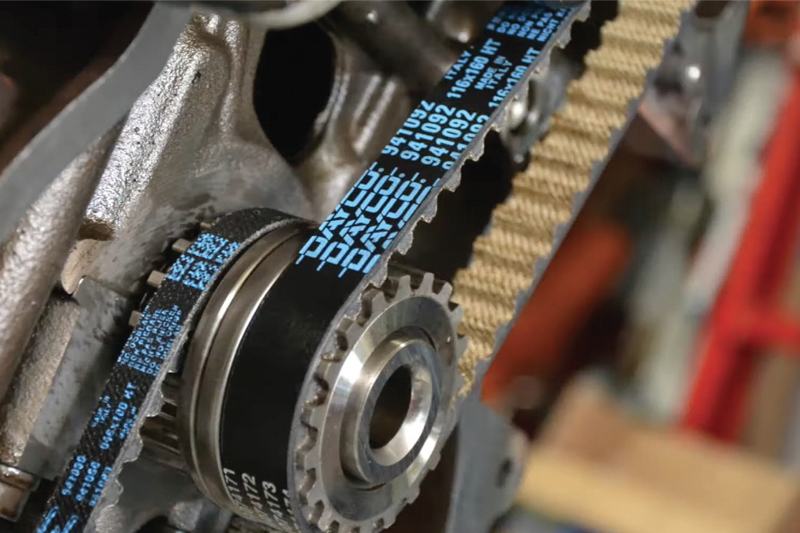

Primarily due to the emission reductions and fuel-saving advantages they facilitate, belt-in-oil (BIO) timing drive systems remain a preferred solution among VMs, as stated by Dayco, and which it views as positive news for the service and repair sector.

The reason behind this encouragement from Dayco, is because these BIO systems will increasingly necessitate replacement over the long-term.

Although some might question the validity of the concept, preferring the traditional chain drive solution, the fact that many VMs have long since moved to belt driven timing systems and a growing number are adopting the BIO route, this means that the replacement process, driven both by the scheduled service interval and by a repair requirement, will be a more frequent workshop activity, and it’s you that will be supplying the new parts that they’ll be fitting.

To help ensure the ongoing reliability of these engines, Dayco, the company that pioneered the BIO innovation on behalf of VMs, such as Ford, PSA and VW, has for some time been highlighting the importance to workshops nationally of carrying out regular maintenance in line with the VMs’ scheduled service intervals. This is because, apart from the catastrophic consequences that would result from belt failure, belt degradation can also have serious implications to several other components, such as the oil pump and brake system vacuum pump.

Dayco National Sales Manager, Steve Carolan, said: “The BIO innovation is a fantastic solution that helps these small and efficient engines to deliver incredible levels of power, alongside exceptionally low emissions and excellent fuel economy, primarily because it reduces friction in the drive system by up to 30%.

“However, to maintain this level of performance and to continue to operate as the manufacturer designed, they need to be serviced regularly and the condition of the belt assessed.

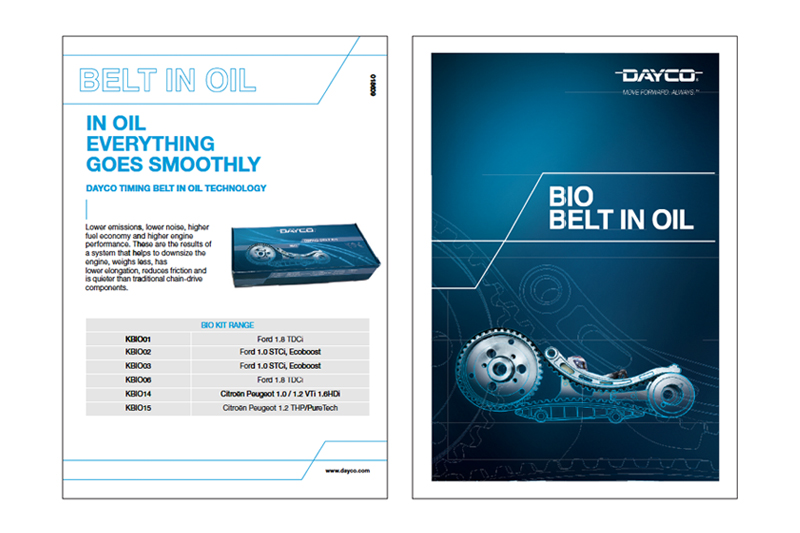

“Naturally, should the belt need to be replaced, as the OE supplier for many BIO applications, we have replacement kits in the Dayco aftermarket range, and this provides factors with a genuine revenue opportunity because over the last year, our sales of BIO kits have doubled, which proves there is a growing demand for the parts and means factors can directly benefit from the BIO revolution.”

Continuing to advance

Following evolutionary developments at OE level, Dayco has superseded its original replacement kits for the 1.2 petrol engine used in many PSA applications, such as the C-Elysee, C3, DS3 and Expert, and the 1.2 diesel engine for models including C3, C3 Picasso, C4 Cactus, 208, 2008, 308 and 3008, previously KBIO07 and KBIO08, with KBIO14 and KBIO15 respectively.

Alongside the positive revenue generation benefits that the growth in BIO applications provides you, Dayco remains active with its customers in the workshop, delivering technical messages, ongoing training and general support, all of which helps to promote sales and reduce the risk of returns and unnecessary warranty claims.

Steve continued: “Part of this process is to react effectively when problems appear, quickly diagnose why they are occurring and then highlight the issues to workshops and technicians, so they are able to follow the correct fitting procedure to replace them successfully, which will increase customer satisfaction and avoid unnecessary warranty claims back to the factor.

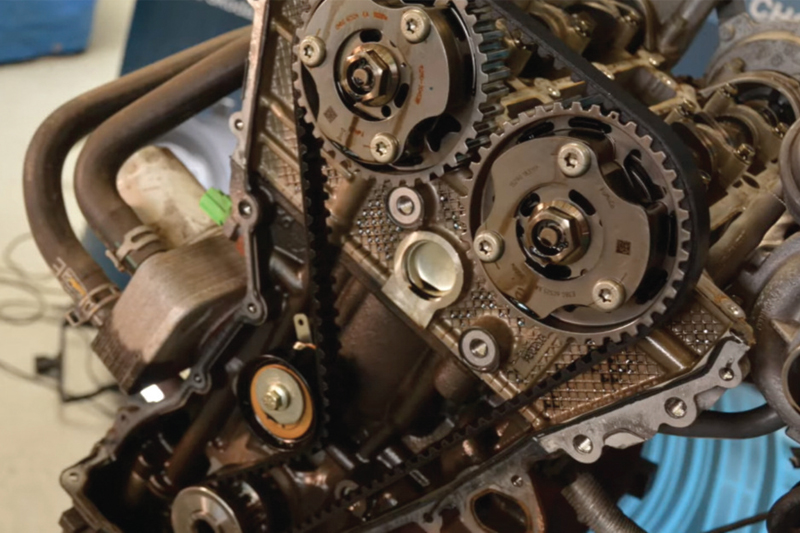

“A perfect example is the two-stage tensioning process that must be carried out when replacing the timing belt on the 1.6 and 2.0 HDI engines that are widely used by Fiat, Ford, PSA and Vauxhall, in many of their popular models in both passenger car and LCV applications. Although the consequences of not following the procedure may not be immediate, because both units are of an interference design, the effect of a subsequent belt failure is likely to be catastrophic to the engine.

“Another topical example concerns oval crankshaft sprockets, which also require specific belt tensioning requirements that if not followed, can end up stripping teeth from the timing belt for example.

“What these examples demonstrate is that even a scheduled service requirement on comparatively common engines requires technicians to follow a specific procedure, not apply a general rule. However, by highlighting these and similar problems at the wholesaler level also allows factors to gently remind their customers of these requirements when the replacement kit is ordered, further reducing the risk of a fitting issue and, therefore, saving both time and aggravation from all sides.”

Look out for part two, which will see Dayco consider the ‘Realities of the EV revolution’