bilstein group Engineering runs through the production processes that the company undertakes to produce febi’s wheel bearing hubs.

On the importance of wheel bearing hubs on febi’s operation, the company’s UK Marketing Manager Traci Varley had this to say: “Since the early pioneering days of the motor car, we have been manufacturing many parts for the motor industry. Wheel hub and bearing assemblies are purposefully built at our production facility, bilstein group Engineering.

“The wheel hub’s fundamental role is to provide the central mounting point for the attachment of the road wheel, brake disc, and wheel bearing, making it a core component of the wheel hub assembly. febi offers a wide range, with more than 600 wheel bearing kits for popular vehicle applications on European roads, all manufactured to OE-matching quality.”

In-house production

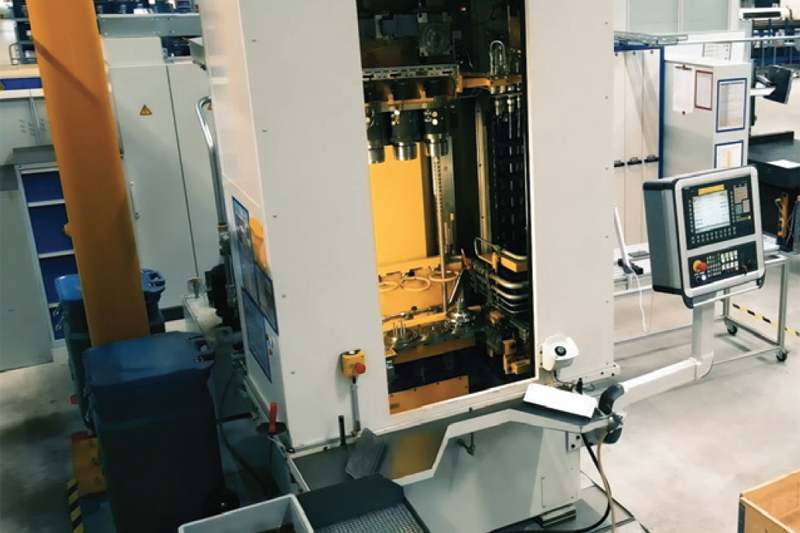

bilstein group Engineering uses its expertise and top quality facility for manufacturing and assembling three different types of wheel bearing hubs: bearings with hub, hubs with steel stud, and hubs with ABS ring.

To guarantee the wheel bearing hubs the company creates are identical to OE, bilstein group Engineering follows a strict creation process. Below, we look at the process in more detail.

Testing, testing, testing

As with any safety-critical component, material checking and functional testing are of the utmost importance. This key process is not any different for the components that make up a wheel hub assembly. All materials used in wheel bearings, hubs, and wheel fastenings are checked for hardness, strength and mechanical properties, and size and functionality accuracy.

Manufacturer’s guarantee

Traci added, “As a parts specialist with manufacturing competence embedded in our history, febi only offers products with the highest degree of installation safety and durability.

“To underline our high product quality standards to our customers worldwide, we provide a three-year manufacturer guarantee for all of our replacement parts. This is a real benefit for everyone that trusts in febi products, and provides an added value for factors, workshops and motorists.

“You can find our full range of wheel bearing kits here.”

The process

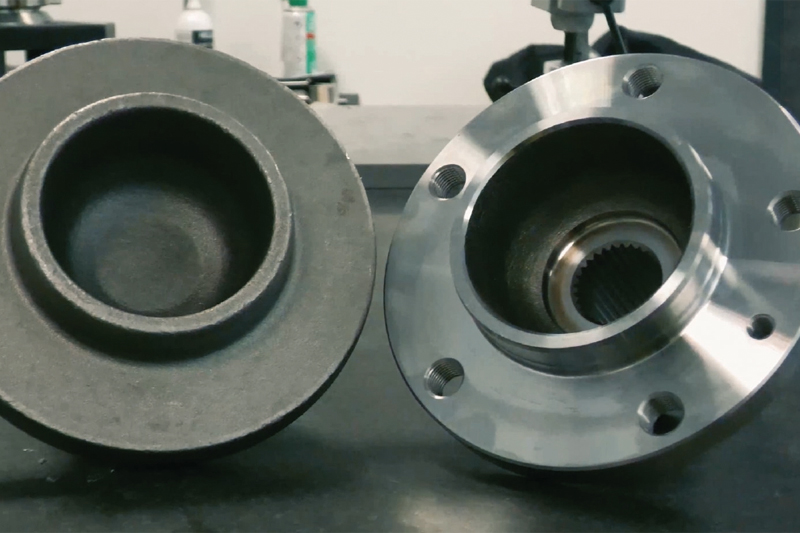

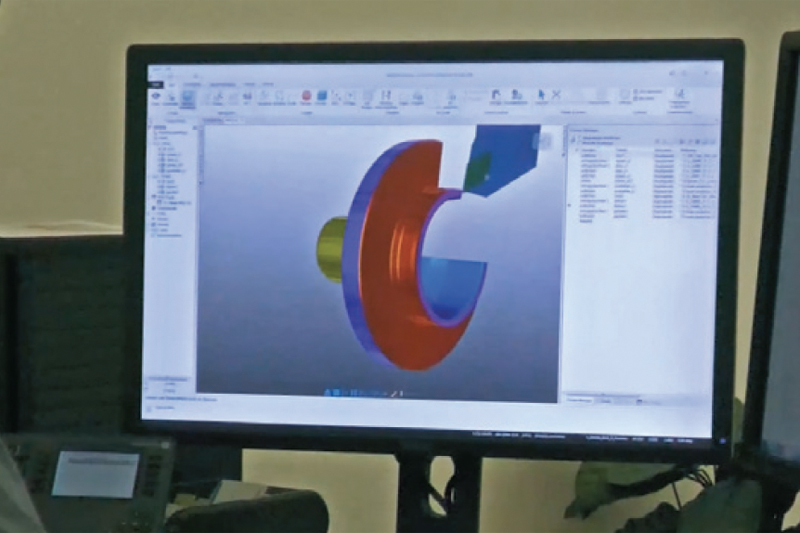

The process begins with a 3D scan of the wheel hub blank.

The blank and the drawings are created from the finished contour in preparation for mechanical processing. After this, a quality assurance check in accordance with the OE part is carried out.

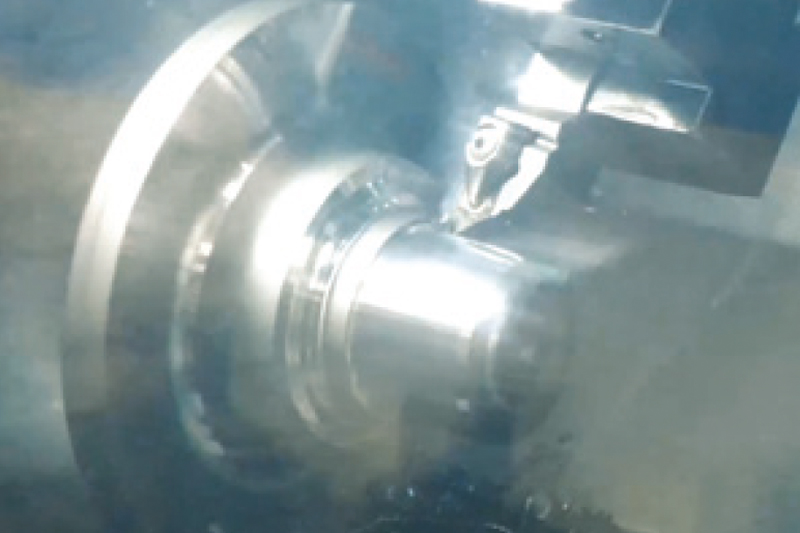

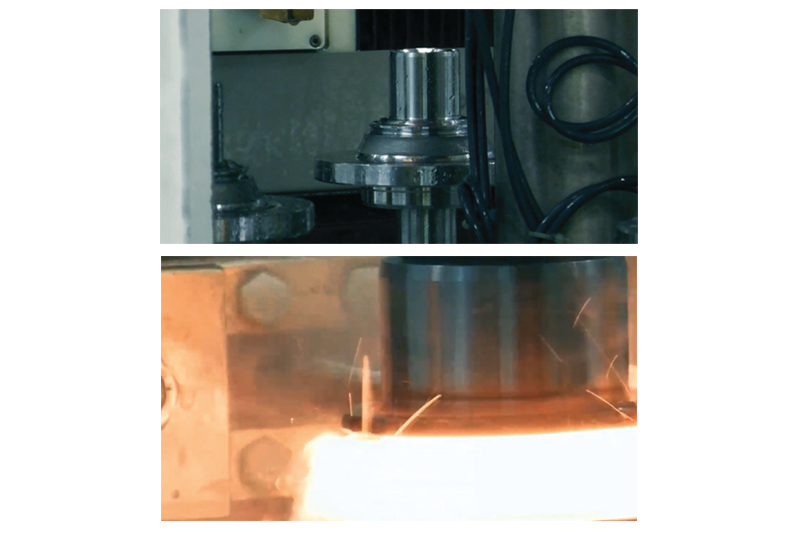

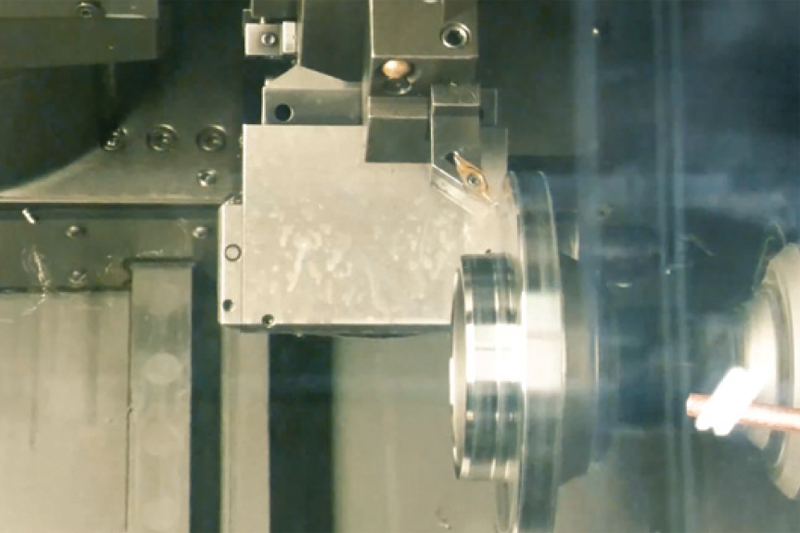

The blank is finish turned on the CNC lathe and the finished product begins to emerge.

The wheel hub is then hardened. According to the company, many of its competitors omit this important step during the production process, which comes at the expense of durability, quality and safety.

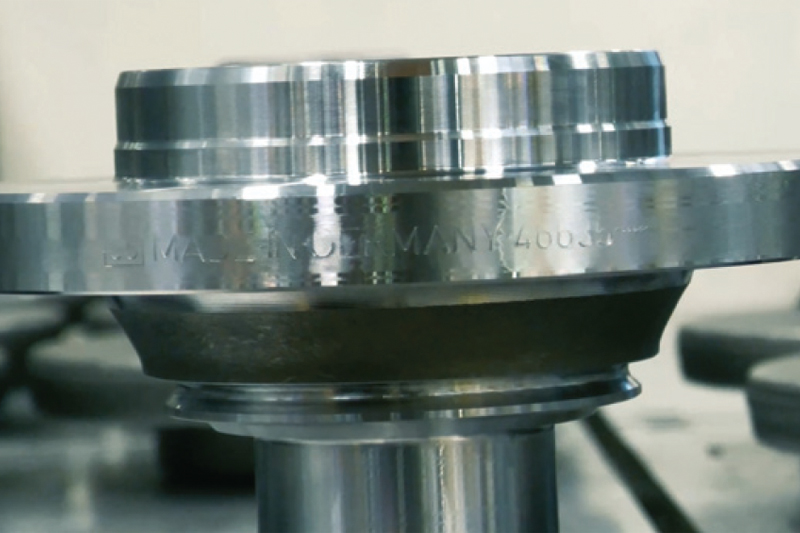

The toothing is abutted. This is a key process for assuring perfect fitment. It also ensures that there will be no movement when engaging the driveshaft into the wheel hub.

After the hardening and toothing process, the wheel hub is finalised to ensure 100% accuracy.

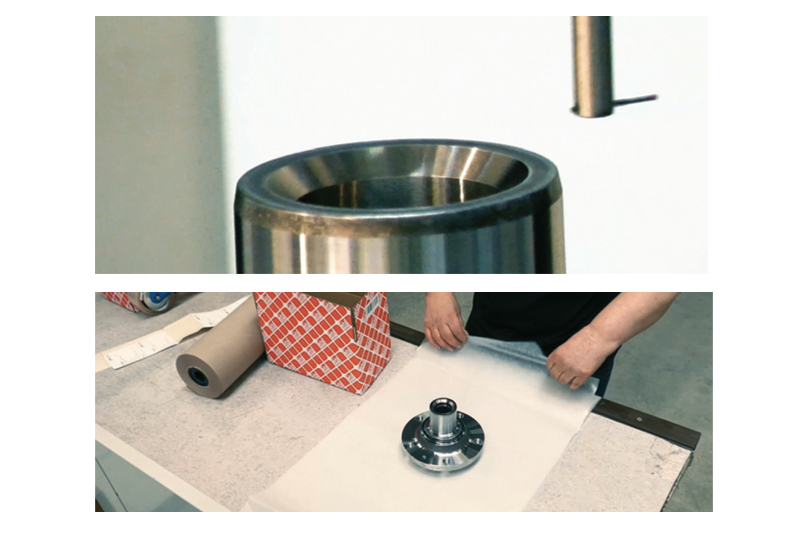

The quality and accuracy of fitment is rechecked and assured by a variety of stringent measurement procedures.

Lastly, final visual inspections are completed and each wheel hub is packed and kitted by hand.

febi’s wheel hub promise

Highest quality – all febi products are said to be designed, specified and manufactured to be direct OE replacements, with its wheel hubs no exception to this

Right range – with over 600 parts in range, the company offers an appropriate and competitive range of wheel hubs

In-house production – at bilstein group Engineering, the company uses its expertise in the production of a select number of wheel hubs. febi is recognised for having the correct know-how and manufacturing competence bearing kits

Associated products – febi provides a substantial range of wheel bearings, wheel speed/ABS sensors and wheel fastenings to complement its wheel hub offer

More profit – by offering a competitive price, febi assures a higher profit to its customers

Fit and forget – factors can have peace of mind with febi’s wheel hubs. The company insists that the parts – backed by its manufacturer guarantee – offer a precise part selection, easy fitment, and safety and durability.