How Allied Nippon’s EV+ range can benefit customers

Following the launch of EV+ brake pads and the Society of Motor Manufacturers and Traders’ (SMMT) announcement that one million EVs are now registered in the UK, Allied Nippon underlines how it hopes its new range will benefit customers.

Allied Nippon has made a bold leap into the future with the introduction of its EV+ range. Specifically engineered for EVs, the brake pad manufacturer believes this new range is set to impact the way you approach braking for the evergrowing fleet of EVs on the roads.

With the latest SMMT figures confirming over one million EVs are now in operation across the country, and the EV share of vehicle parc steadily increasing, Allied Nippon’s move to launch a dedicated EV+ range could hardly have come at a better time, according to EV+ Project Lead and Allied Nippon Development Manager, Matt Ellis.

He continued: “The EV market demands specialised solutions, considering the unique challenges posed by the increased weight and speed of these vehicles. EVs are known for their rapid acceleration and substantial weight due to large battery packs, necessitating a need for a dedicated brake pad specification.

“Allied Nippon was early to develop the EV+ range; prototypes were initially shown at Automechanika Frankfurt back in September 2022, but our strategy was to wait for the market to be ready for the product range. With the UK EV parc now topping seven figures, the time has come for EV+.”

The advantages of EV+

The EV+ range is not a rebrand of an existing product, a confident Matt said, but a “ground-up development” tailored to meet the distinctive needs of EVs. The primary objectives were clear: enhanced stopping power and ultra-low noise. Matt believes Allied Nippon has achieved this through its development processes, by combining a new friction compound with a scorching treatment and its BRAKEBOOST Instant Friction layer.

The weight and speed of EVs require a capable braking system. Consequently, Allied Nippon’s development team has introduced a new friction compound in EV+ brake pads, heat-treated through scorching for enhanced stability. This, coupled with the BRAKEBOOST Instant Friction layer, ensures “superior stopping power”, addressing the challenges posed by heavy EVs.

Furthermore, recognising the smooth driving characteristics of EVs, Allied Nippon has placed a strong emphasis on noise reduction. With EVs being quieter than their ICE counterparts, EV+ brake pads achieved an AA-rating during testing, with a peak output of just 88dB.

Considering a sound below 70dB is essentially inaudible to those inside the vehicle, this peak output shows the success of Allied Nippon creating a hushed braking solution.

Upselling opportunities

Matt underlined the upselling opportunity that EV+ provides: “EV+ presents a chance to not only meet the evolving needs of EVs but also to elevate the customer experience and drive additional revenue. By effectively communicating the benefits of enhanced stopping power and ultra-low noise, EV+ premium brake pads offer a genuine opportunity for aftermarket businesses to increase their EV revenues.

“As a specialised EV product, EV+ is competitively priced whilst remaining aligned with Allied Nippon’s ethos of offering world class quality. The unique selling points of EV+ position it as more than just a braking solution; it becomes a value-added proposition for customers seeking the right service parts for their EVs.”

Elevating profits through premium performance

As EVs continue to make their indelible mark on the automotive aftermarket, Allied Nippon’s EV+ brake pads are primed to play their part.

Matt concluded: “The upselling potential embedded in EV+ goes beyond offering a product; it’s about providing a greater experience for EV owners and, in turn, maximising revenue in the era of electric mobility. Don’t just meet the demand; exceed expectations and drive revenue growth with Allied Nippon’s EV+.”

Range focus

EV+ will be available to stock at the end of March, with the initial range catering 37 popular part numbers, including the Nissan Leaf, Renault Zoe, Tesla Model 3, and Jaguar I-PACE. Additionally, where the model is an exclusive EV application with no ICE variant, EV+ will be the only Allied Nippon reference available moving forward.

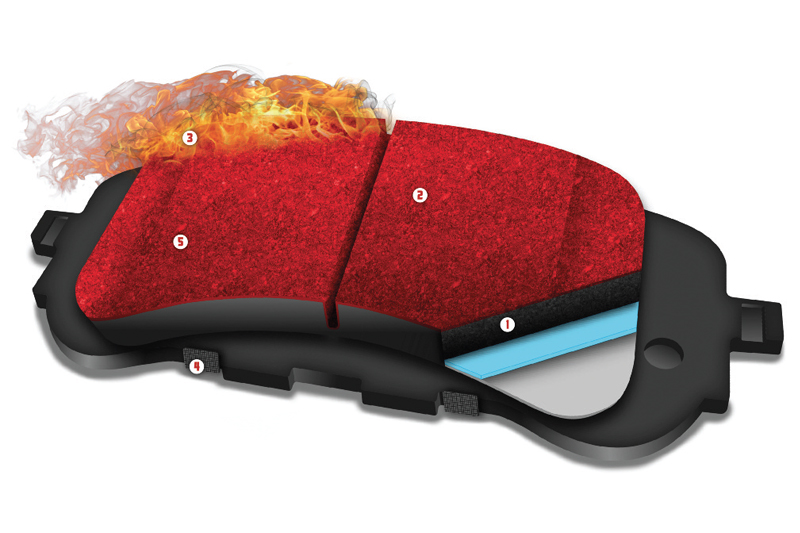

The EV+ range boasts a host of features designed to optimise performance and increase profitability for you and garages:

1) Friction material: Specially selected for low noise and stable stopping power.

2) BRAKEBOOST Instant Friction: A resin-based compound for instant friction during bedding-in.

3) Scorching: A heat treatment process for improved friction stability, especially at high temperatures.

4) Multi-material backing shims: Reduce vibration and eliminate unwanted noise.

5) OE matching chamfers: Ensures effective contact between pad and disc, reducing noise during operation.

6) Identification and branding: Clearly marked with part numbers, batch codes, and ECE R90 reference for certification.

7) Environmentally sensitive: Certified copper-free and ‘N’ rated by AASA, safeguarding against marine habitat contamination.