In light of the safety-critical nature of steering and suspension components, Aisin discusses why these parts are essential.

Aisin Europe Aftermarket has made the decision to offer a new steering and suspension product range. The company has developed a full catalogue in order to cover more than 85% of the Asian and European car parc. The range is said to be comprehensive, covering all of the principal vehicle functions – driving, turning and braking – and includes clutch, brake, drivetrain, chassis, engine and cooling systems, vehicle body parts, and steering and suspension parts.

Why a steering and suspension range?

After brake pads and brake discs, steering and suspension parts are the second most critical component on vehicles that contribute to a driver’s safety. For this reason, regular MOT vehicle inspections include a specific focus on steering and suspension systems. A failed inspection means that motor vehicle owners will need to replace or repair these components in order for the car to pass its inspection.

As extreme weather becomes more prevalent, there is greater potential for damage to occur to the steering and suspension system. The use of salt and gravel, coupled with increased potholes and cracks in the road, for example, can significantly decrease the lifetime of vehicle components.

Reduced funding for infrastructure across the world means that the quality of road conditions will only continue to degrade, and, as a result, demand for suspension and steering components will increase. This, coupled with the fact that vehicle owners are keeping their cars for longer than ever, means that it is increasingly important to have a reliable supplier of high-quality parts.

When speaking about suspension components, the shock absorber tends to come to mind first, but this intricate network of interdependent components starts with the tyre. A poor or failing component of this type has the ability to speed up the wear and tear of the chassis parts, and therefore make the car unsafe to drive.

As the steering and suspension system is the second most frequent item to fail in annual technical vehicle inspections, it is important to ensure that only the highest quality parts are fitted.

Aisin claims to provide premium quality products with a varied range of hard parts and rubber-to-metal parts. Depending on the material used, the company’s aftermarket parts are produced using either high-grade steel or aluminum.

All steel parts receive a cataphoresis coating, which provides a 10-year guarantee against corrosion. The current trend in practice is for vehicle manufacturers to use more aluminum to reduce vehicle weight in the chassis, which can cause a 4% improvement in fuel consumption and CO2 output. This is also the case for steering and suspension components, and Aisin adheres to this trend in the production of its steering and suspension components.

Aisin has developed the following Original Equipment (OE) quality components:

- Ball joint: used in tie rods, control arms (supporting vehicle’s weight) and stabiliser links

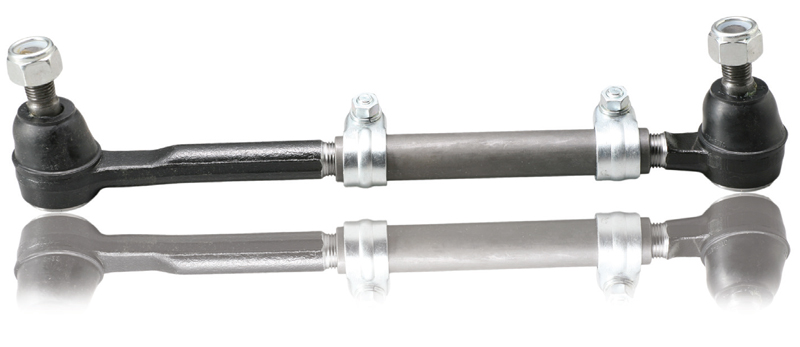

- Centre rod assembly: part of the linkages transferring steering motion to the wheels

- Control arm/trailing arm bushings: connects suspension components to the chassis

- Idler arm: providing pivotal support for the steering linkage, bolted to vehicle frame

- Pitman arm: connected to the steering box, converting angular to linear motion

- Rod assembly: steering linkages

- Rod/strut, stabiliser: also known as anti-roll or -sway bar to reduce vehicle roll

- Stabiliser mounting: mounting of the stabiliser or anti-away bar to the control arm

- Steering arm: connecting steering box to the wheels giving directional control

- Tie rod axle joint: connecting steering linkages to the wheel

- Tie rod end: connecting steering linkages to the wheel

- Track control arm: hinged suspension link that connects suspension to wheel