Modern, highly stressed suspension spring designs, combined with potholes, speed bumps and salt on the roads in winter, mean that coil springs, especially those of lower quality, are increasingly prone to breakage. Peter Dancer, UK Business Development Manager at Kilen Springs, tells us more.

With breakage being the main reason for spring replacement, spring producers strive to maximise fatigue strength. A springs’ fatigue strength is essentially the maximum stress it can withstand without breaking. So, what affects fatigue strength?

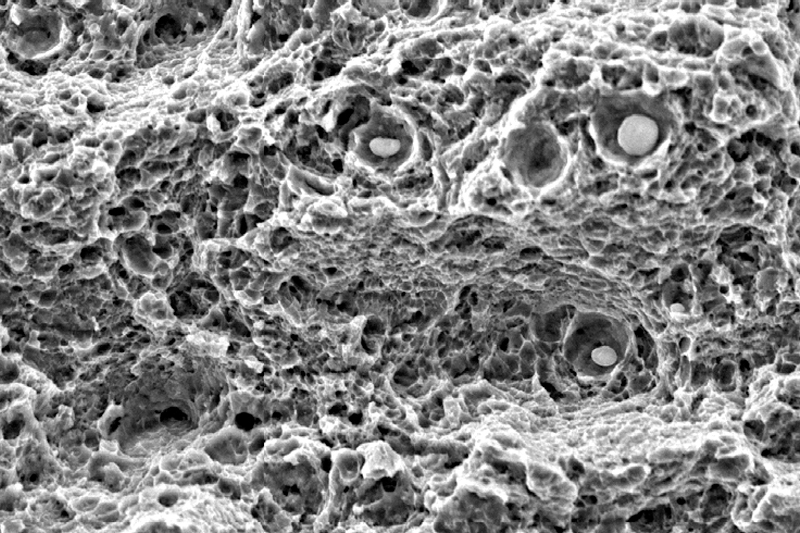

Poor quality spring wire, containing non- metallic inclusions (Fig. 1), influences fatigue strength and will lead to premature breakage. Therefore, the risk of breakage is significantly greater for ‘budget’ springs that use lower-quality steel.

Heat treatment is a critical part of spring manufacturing and, if not performed to OE standards, can leave a spring too brittle. The more brittle the steel, the more sensitive it is to defects such as corrosion, which results in lower fatigue strength and an increased risk of premature breakage.

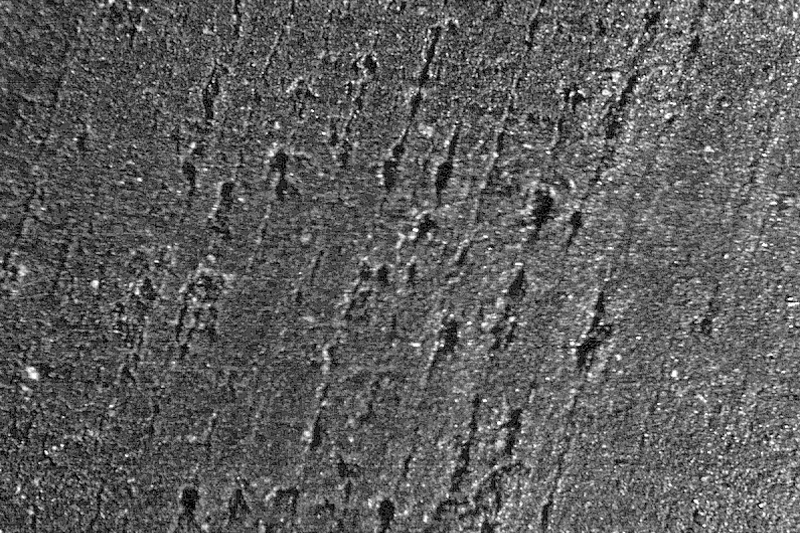

Surface defects also lower fatigue strength and lead to early breakage. Lower quality spring steel can have many microscopic cracks in the material surface, increasing the risk of breakage (Fig. 2). Use of OE quality spring wire, combined with shot peening and pre-setting will improve fatigue strength.

Shot peening is a treatment where the complete surface of the spring is bombarded with millions of tiny steel shots. This closes any potential micro fissures, and introduces a positive residual stress in the material, whilst also preparing the steel for surface treatment.

The pre-setting operation is a manufacturing stage where the spring is compressed to implement a positive residual stress. All OE quality springs, where the design requires it, will be pre-set.

Coil springs are under continuous attack from the road below. The sudden impact of a pothole is a well-documented cause of suspension damage. Road debris is also a significant danger. This exposes the bare steel which, if untreated, will quickly rust.

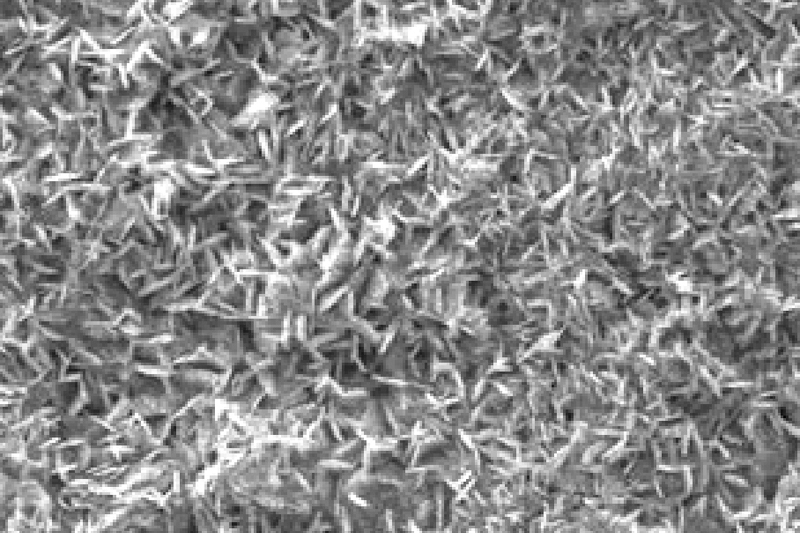

To reduce the risk of premature failure, a spring should employ a surface treatment which provides protection between the steel and the paint layer. The technique is normally a special zinc phosphate method. The substance contains zinc ions, a less noble metal than iron, which gives the required galvanic protection. An OE quality spring will be zinc phosphate (Fig. 3), will be protected with a powder coat paint system – of 50 micron thickness – to ensure suitable protection against corrosion, and will have a good cosmetic finish.

As grit salt is spread on the roads during cold weather, it mixes with surface water to form an abrasive paste, grinding the protective paint off of the spring and dramatically accelerating the corrosion process. Cold temperatures affect the toughness of the steel, meaning that the steel becomes more brittle and is more liable to cracking. Minute cracks can form on a rusty, damaged spring surface and, given repeated compression cycles, will increase in size over time. One of these cracks will eventually propagate, and it is not uncommon for coil springs to fail catastrophically on a cold winter’s morning; the shock impact of hitting a speed bump or descending a kerb can be enough to cause a crack to propagate across the full diameter of the spring wire, often quite audibly.

How to win this winter

In today’s market, factors know how crucial availability and range is, especially during peak season. Factors should aim to have at least the top 750 part numbers on the shelf at all times, covering just over 90% of demand. Kilen supports its stockists with a range re-profiling service to ensure that their stock profile is continually updated with the very latest references, meaning that the most popular springs are on the shelf and ready to go.