How is Carwood helping factors stay ahead?

Carwood believes forward-thinking suppliers – those that offer more than just parts – are the ones that you should be looking to partner with in an ever changing marketplace. PMF recently put some questions to Carwood Deputy Managing Director, Simon Quantrell, to learn how the company is evolving its offering in order to give its factor customers a competitive edge.

Q. How has Carwood adapted its product offering to meet the evolving needs of motor factors, especially with the growing demand for parts related to electrification and modern diesel systems?

A. The rise of hybrid and EVs, along with more advanced internal combustion systems – such as Euro 6 and beyond – means that motor factors must stock a broader range of increasingly sophisticated parts. As a powertrain-agnostic supplier, covering diesel, gasoline direct injection, electric or a combination of the two – Carwood is positioned to help factors navigate this rapidly changing landscape.

For conventional powered vehicles, we are continuing to develop new remanufacturing programmes, within two to three years of vehicle launch. This includes the Citroën Berlingo, Peugeot 208, 308 and 2008; BMW 1, 2, 3, 4 and 5 Series; Jaguar E Pace, F Pace, XE and XF, and the Land Rover Discovery Sport and Range Rover.

Where a repair solution is not yet available, we stock a wide range of new OE units from the likes of Bosch, Delphi, DENSO, BorgWarner and Mitsubishi, to ensure we can support the vehicle from day one. Coupled with cost-effective and sustainable, reman and repair solutions, this means we’re able to service a vehicle throughout its entire lifetime.

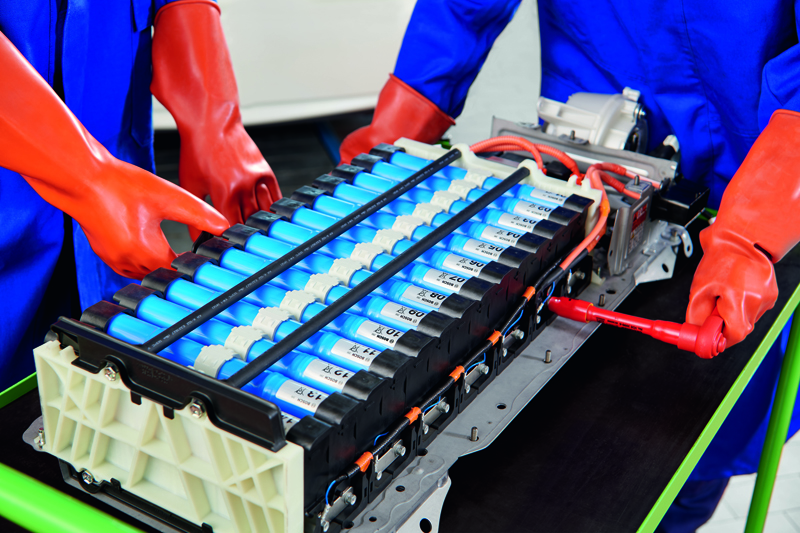

As the industry continues to shift towards hybrid and EVs, however, so too will our portfolio. Our latest launch – highvoltage battery repair for hybrid and EVs – is yet another example of how we’re continuing to stay relevant and help factors tap into the EV opportunity.

Q. How important is remanufacturing to Carwood? How would Carwood summarise the market recognition of remanufacturing?

A. No pun intended, but remanufacturing is ‘core’ to our business. And with growing market and regulatory emphasis on sustainability, combined with increasingly cost and environmentally conscious customers, it will become increasingly so for both factors and the wider automotive industry.

Whilst the benefits of remanufacturing are relatively well understood within the aftermarket, unfortunately, some still associate remanufacturing with secondhand and believe it’s lesser quality. Nothing could be further from the truth.

Because, whilst technically it is secondhand, the simple fact is we return a used part back to its original specification – sometimes better – so at the end of the process, there is an as-good-as-new product. Yet because we reuse the core, it saves valuable material, energy and waste to landfill – and you and your customers money.

Q. How is Carwood working to strengthen supply chain reliability and availability of key product lines for factors?

A. Driven by technology and regulatory change, OEMs are phasing out parts faster than ever before; electronic components that were once on a 10-year lifecycle, may now only be supported for a handful of years. This creates real challenges for the aftermarket, but also opportunities for innovative remanufacturers, like Carwood.

To help maintain part availability and fill any gaps, our in-house purchasing team routinely monitors product lifecycles. If there’s a risk of shortages, we forward-buy and hold stock to safeguard against potential disruptions.

For hard-to-find or obsolete parts, our engineers can also recreate parts, that meet or exceed the original specifications – even if the original drawings are no longer available. Together with our proactive range management, this ensures ‘cradle-to-grave’ support for a wide range of vehicles.

Our biggest challenge – a good one to have – has been keeping up with demand. To do so, we are continuing to expand production and warehousing capabilities across all our sites. We’ve just commissioned two of the latest Carbon Zapp test benches, taking our total production test capability to over 30 benches. Also, at our turbo facility in Nottinghamshire, we’ve invested in new strip and clean machinery, in order to speed up the build process and improve the finish of the housing. We’ve also added a mezzanine floor, providing additional warehousing space.

Q. Margins and value-added support are essential for factors – what commercial or logistical support does Carwood offer to help factors sell more effectively and profitably?

A. We recognise that every step of the supply chain is under pressure – and motor factors are no different.

Although reman is already a costeffective, proven-quality alternative to new, we’re always looking at ways we can improve on both; for example, we’ve recently reduced the price of two of the market’s fastest moving injectors, whilst also removing the surcharge, helping you to boost profitability and gain a competitive edge.

On another, fitted to the ever-popular VAG 1.6 TDI engine, we’re now using a brand-new OE solenoid in every unit. So, you still get the same reliable, highly accurate engine, fuel and emissions performance as the OE – but for longer.

We also know your time is precious, which is why we’re shifting to digital solutions that will help streamline the ordering process, enhance stock visibility and improve operational efficiencies. Whether it’s our own online cataloguing, ordering and returns platform – visit here – or making our parts available on TecDoc and TecCom, it’s all part of our mission to make Carwood even easier to do business with and your business more profitable.

Coupled with optimal stock holding, flexible warehousing and next-day delivery for factors, we can ensure fast and reliable access to the parts you need, when you need them.

Q. Training is often geared toward technicians – but how does Carwood support the product knowledge and sales confidence of factor staff?

A. Agreed, but in order to stay competitive, motor factors will need access to training and knowledge too.

For part identification, cross references, live stock and pricing, our platform and the likes of TecDoc, MAM, provide quick, reliable answers whilst your customer is on the phone. Of course, you can talk to us too; our customer service team is on hand to answer any questions you may have.

To help staff answer technical queries confidently, either access our technical hotline or visit the resource library on our new website. We also provide branded materials, such as brochures, sales sheets, application guides, to support the sales conversation and help staff articulate a clear value proposition.

Of course, platforms like PMF, are another great way for us to share knowledge, be it a thought leadership piece on the key trends shaping our industry or advice on up-selling our parts.

Q. What does the future look like for Carwood – and how will the company continue to grow its relevance and offering to the factor network?

A. In one word: positive. To ensure it stays that way, we will continue to expand our product range. This will include regular new reman launches for fuel injection systems, turbochargers, rotating electrics, DPFs and hybrid and EVs, and wider access to OE parts through our relationships with the leading OEMs.

To help you find and order these and other parts, quickly and accurately, we will continue to strengthen our digital platforms. And we will add yet more production and warehousing capacity, backed by next-day delivery across the UK, to help us get it to you just as fast.

Of course, all of this would be pointless without our factor customers. Which is why we will continue to offer even better service, more competitive pricing, stock packages and joint promotional activity. All with the aim of increasing our joint turnover, profitability and customer satisfaction.