Turbochargers set for strong growth

Notwithstanding EV momentum, turbocharged engines continue to dominate workshops, according to Nissens Automotive. With double-digit market growth forecast, the aftermarket stands to gain from rising demand, advanced technologies and expanding replacement opportunities – here’s Head of Marketing, Group Content Director, Jan Zieleskiewicz.

Despite the rise in EVs, turbocharged ICEs remain the backbone of the service and repair sector. Industry forecasts even point to more than 10% growth in the turbocharger market by 2030. The reasons are clear: stricter emissions standards, widespread engine downsizing and the increasing complexity of turbo technologies.

For us, this is positive news. Winning business away from franchised dealers not only creates additional revenue streams, but it also means our existing customers can purchase more from a single source – improving efficiency across the board.

Research, development an testing.

Our approach to aftermarket turbos is rooted in investment, detail and experience. We put significant resources into research and development, back it up with meticulous testing, and confirm results through extensive field examinations. By drawing on our own expertise and working with external institutes, we’re confident that our products don’t just match OE standards – they often exceed them.

Premium materials are central to this. Many of our turbo models are designed to cope with modern, high-performance engines; for example, turbos built for engines operating under extreme combustion temperatures – a consequence of tighter emissions rules and lean combustion strategies – incorporate heatresistant alloys, such as D5S and 1.4848. In the heavy-duty segment, several of our truck turbos feature titanium compressor wheels for added durability, while our highend passenger car models integrate advanced electronic actuators.

Designed for success

Our mission has always been to fuel the commercial prosperity of our customers. This has driven us to develop one of the widest ranges in the market: close to 450 part numbers covering all segments and technologies, from free-flow and wastegate units to advanced variable turbos with sophisticated electronic actuators.

Alongside this, we’ve expanded into electrical and smart parts, strengthening our capabilities in microengineering, electronic design, testing and manufacturing. For you, that means not just product range but also confidence in supply. Today, we guarantee turbo availability, complemented by five additional product lines within the efficiency category.

To support this, we’ve created a detailed video guide to our turbo range: here. Aimed directly at you, the distributor, it provides a clear overview for those factors seeking a reliable partner in this fast-growing product category.

Right first time installation

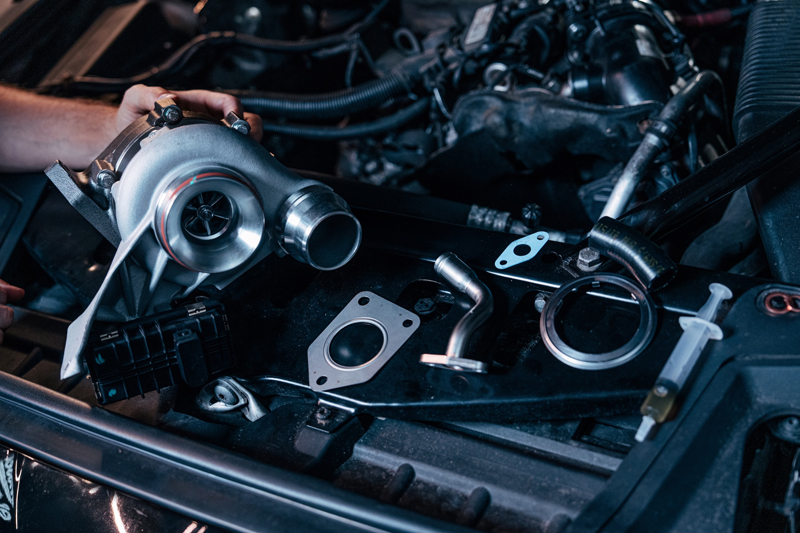

Workshops know that technical support and ease of installation make all the difference. That’s why we’ve invested heavily in simplifying the process, giving technicians the confidence to complete repairs properly the first time.

Our support package includes a dedicated turbo hotline, e-learning modules, live training sessions and a wide library of technical resources. Every turbo we supply is a brand-new unit, manufactured from quality materials – which eliminates the need to return old units or pay a surcharge. Each is packaged to withstand handling and transit, protecting stock as well as reputation.

We’ve also built the ‘first fit’ concept into every box, ensuring that essential parts, such as gaskets, stretch bolts and even a syringe for pre-lubricating the turbo shaft are included. Where necessary, oil feed lines are part of the programme too. Together, these measures simplify installation, cut down on rework, and give workshops the tools for a successful repair right from the start.

Technical Advice

Our technical support doesn’t stop at installation. We see it as a responsibility to share insight into common issues and their underlying causes, helping technicians complete thorough and lasting repairs.

Take the widely used 1.6L PSA DV6 diesel engine. When serviced correctly, it’s a solid and reliable unit – but if oil changes are missed or filters skipped, lubrication related failures become a real risk. That’s why we offer detailed advice on both the symptoms and root causes, ensuring technicians have the knowledge to protect customers from repeat failures.

To back this up, we’ve developed four tailored replacement turbo kits for the DV6 – two ‘basic’ and two ‘plus’ versions – covering both DPF and non-DPF variants. The basic kits include key components, such as oil pickup, feed and return lines, plus banjo bolts and flanges. The plus kits go further, adding oil filters with gaskets, as well as vacuum pump and oil cooler gaskets. Combined with our replacement turbos, they provide a complete and dependable repair solution.

Market Feedback

The response across Europe has been overwhelmingly positive. Distributors value the range, workshops appreciate the ease of installation, and both recognise the competitive pricing. Above all, the feedback reflects reliability – a key factor in building trust in any aftermarket programme.

As turbocharged engines continue to dominate, demand in the aftermarket will only grow. We’re ready for that challenge, with the products, insight and support needed to help the trade succeed in a changing market.