Febi’s solution to common Ford Mondeo fault

Charles Figgins, bilstein group’s product and technical information manager, highlights “one of the most commonly affected components” on a fourth generation Ford Mondeo (2007-2014) and febi’s solution.

The Mondeo was a strong player in the family and fleet car market, lauded for its refined ride, ample load capacity and all-round practicality. Its popularity among private users, company car fleets – and even emergency services – cemented its reputation as a dependable workhorse. Underneath its practical shell lies an independent multilink rear suspension system, a design shared with its siblings, the Ford Galaxy and S-Max, as well as several Volvo models.

This advanced rear suspension came in several versions – standard, sports and heavy-duty – with or without self-levelling dampers or electronic control; however, most of the underlying hardware remained largely consistent across variants.

As with all suspension systems, this network of bushes, joints and bearings is critical for maintaining stability, comfort and drivability. Over time, wear and tear on these components can lead to compromised ride quality, vague steering and reduced braking performance due to uneven tyre contact with the road.

Common wear point: Rear trailing arm bushes

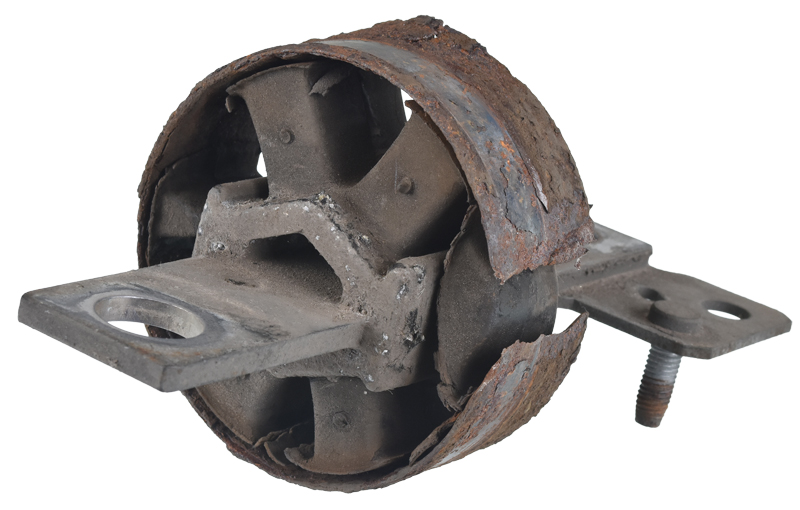

One of the most commonly affected components on the Mondeo’s rear suspension is the rear trailing arm bush. These bushes are vital to maintaining suspension alignment. Once degraded – often seen in torn rubber or corroded outer casings – the back of the vehicle may adopt a slumped appearance, indicating a loss of suspension geometry and effective control.

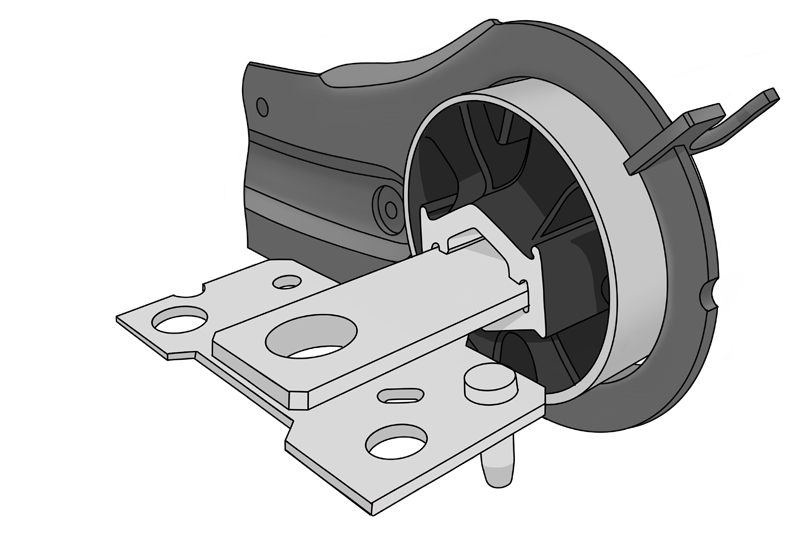

Fortunately, these bushes can be replaced individually without the need to swap out the entire trailing arm, offering a cost effective repair solution. With the right press tool, the old bush can be removed and a new one installed. Technicians should take care to align the new bush correctly according to the indexing marks.

Solution

At febi, we offer replacement bushes engineered from vulcanised natural rubber with an outer metal casing designed for easy installation. These parts offer longlasting durability and the mechanical properties needed to cope with daily driving stress. The bushes also include a slight leading edge on the bush casing to assist in accurate fitment.

Beyond replacement bushes, we recognise the challenges faced by workshop technicians, particularly the difficulty of reusing original bolts and fixings. Exposure to the elements means these parts often corrode, seize or weaken, and are no longer suitable for reuse. This is where our repair solutions come into play.

For example, our axle beam mounting kit (43403) provides bushes for both sides of the vehicle along with new, high-tensile bolts. The ProKit (46000) cross strut kit goes further, supplying not only the bushes and bolts but also suspension links.

Each bolt included in the repair kits features high tensile strength for critical load-bearing applications, anti-corrosion coating for longevity, leading threads for easier installation and thread-lock treatment to resist loosening over time.

These kits are designed to meet or exceed OE specifications.