ELTA reveals new bulb testing facilities

ELTA Automotive has revealed details of its light measurement and photometry test facilities, which the company believes is only one of a handful in Europe.

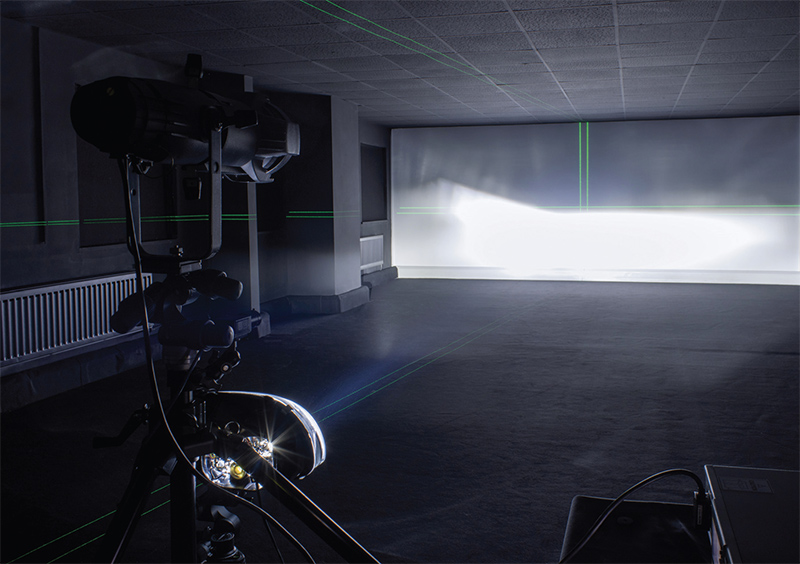

Developed in collaboration with, according to the company, expert manufacturing partners and having a no-expense-shared approach, this facility is designed to advance quality assurance and testing capabilities.

At the heart of the new site is a five megapixel imaging photometer with a matched lens and Sony’s Pregius CMOS sensors. ELTA is confident this equipment will enable it to accurately measure light output and beam patterns in compliance with ECE Regulation 112, ensuring the highest standards for its products.

ECE R112 is a standard established by the United Nations Economic Commission for Europe to ensure the performance, safety and design consistency of headlamps producing an asymmetrical passing beam (low beam) or driving beam (high beam).

The regulation sets strict photometric requirements, including light intensity, beam distribution and uniformity, to ensure adequate road illumination while minimising glare for oncoming traffic. Compliance with ECE R112 is critical in meeting safety and legal requirements in regulated markets.

ELTA Automotive Marketing Manager, Tim Brotherton, said: “All ELTA bulbs are manufactured to meet regulation R37 standards and achieve e-mark status. Key aspects of R37 compliance, such as geometry, photometry and performance metrics, like wattage, luminous flux and kelvin temperature, are rigorously tested by our manufacturing partners throughout manufacture and beyond. At our new facility, we can now test bulb performance in headlamps to ensure compliance with Regulation 112, verifying optimal light output and precise beam patterns.”

The extensive space dedicated to the facility highlights ELTA’s commitment to the cause. Purpose-built for the new equipment, the area is powered by a dedicated programmable AC power source to maintain a controlled environment and consistent testing conditions.

ELTA hopes this investment reinforces its reputation as a “trusted aftermarket partner”, a belief stemming from its ability to “meet and exceed the standards of both OE and competitor products”.

Tim added: “At ELTA, we’re immensely proud to support the aftermarket, providing a real alternative to OE products that empowers distributors to remain competitive and win business from main dealers. We believe choice is essential; one price point cannot meet the diverse needs of the market.”

Road safety at the heart of this investment

The new test facility has been developed with road safety in mind; the equipment means light should be where it’s needed – on the road! – while glare should be a thing of the past too. The precision should help protect other road users from being dazzled, making it safe for everyone.

Tim said: “Our advanced testing processes ensure ELTA bulbs deliver clear visibility for drivers while safeguarding the safety of others.”

Inspiring confidence

Throughout 2025, ELTA plans to invite customers, industry figures and the trade press – Professional Motor Factor included! – to check out the new testing facility, offering a firsthand look at the company’s technical capabilities. ELTA hopes these visits will serve to reinforce the importance of championing the automotive aftermarket while building trust and confidence in its products and services.

Tim concluded: “Our new light testing facility isn’t just about advancing our capabilities, it’s about inspiring our customers and distributors. We want to demonstrate that exceptional quality, performance and safety are achievable without compromising on affordability or the freedom of choice that defines the aftermarket.”