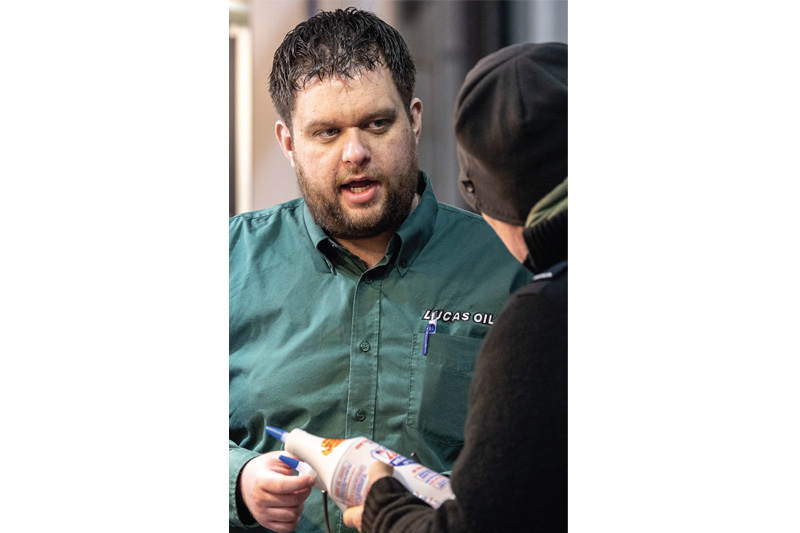

We sat down with Lucas Oil Sales and Operations Director, Dan Morgan, to discuss all things additives, the impact of the Lucas Oil Academy, ‘repair over replace’ and continuing challenges with E10.

Q. Thank you for contributing to the additives focus – quite simply, what do additives mean to Lucas Oil?

A. “We are primarily an additives company, so if I answer that “additives mean quite a lot”, it would be correct in terms of total operations, total volume and total revenue. Our engineers have developed automotive products that can be used in cars, motorcycles, trucks and buses. Most are engine oil systems specific, while others are for fuel systems or cooling systems. We have designed additives that can be used as problem solvers, as general maintenance solutions and as part of preventive maintenance programmes. And our additive technology has evolved. We also have products that can be used in more than one system. Lucas Oil has always been a family-run business, and I think it’s fair to say that our additives range has helped us to become one of the world’s largest manufacturers of oils, additives and workshop lubricants.”

Q. Extending the life of a component – repair rather than replace – is a strategy of Lucas Oil’s – how is it achieving this?

A. “More recently, we are achieving this through the activities of our Lucas Oil Academy (LOA), which is broadcasting the message that “oil alone isn’t enough”. Quite simply, this means that while oils help reduce engine friction and prevent engine wear, additives take matters a few steps further. For example, Heavy Duty Oil Stabilizer prevents thermal breakdown, increases the life expectancy of an engine and prevents damage from dry starts by increasing lubricity. That’s a few achievements that we can demonstrate right there.

“We are also delivering the message that component removal and replacement is not necessarily the only answer. For example, a squealing steering rack or one that seems to be experiencing ‘hard spots’ might not have to be removed and then replaced. It might be that a greener and more sustainable solution is to treat the existing rack with our Power Steering Stop Leak. It reduces slack, squeals and hard spots in worn rack and pinions with results that are immediate and long lasting.”

Q. How is Lucas Oil communicating this message to motor factors?

A. “We have always provided motor factors with technical support and a technical hotline, while the LOA was working with colleges to deliver the message to young mechanics. We are now working directly with motor factors to take the message to their garage and retail customers. We’re helping to change attitudes; for example, Lucas Oil disagrees with engine flushing practices. We believe abrasive, solvent based engine flushes do more harm than good in the long run. Flushing leaves behind residue agents that contribute to the early breakdown of the new oil.

“Our answer is Complete Engine Treatment. This helps to clean engines from the inside. It’s an additive. It acts alongside the existing oil. It is not an engine flush. Moreover, the additive technology is such that it can be used within fuel systems too, to achieve similar cleaning goals.”

Q. Why should factors be sharing these points with their workshop customers?

A. “We spoke earlier about extending the life of components and about providing more sustainable solutions. Garages are always looking for opportunities to “save the customer money”. Utilising additives can help achieve these goals and create a more efficient workspace at the same time. This means that sometimes they can save time on some jobs by offering customers a faster, more efficient and more cost-effective solution. Additives also free up a mechanic’s time for bigger – and potentially more profitable – jobs.

“Customers want solutions that work and don’t cost the earth. Additives provide alternative ways to do this; for instance, it might be by using a problem-solving additive like Engine Oil Stop Leak. An additive like Upper Cylinder Lubricant can help steer a possible engine emissions test failure to an MOT pass certificate.

“Each will help the consumer save money in the long run, while providing workshops with opportunities to upsell and increase profit margins.”

Q. What other trends has Lucas Oil observed in the market?

A. “The average age of cars is increasing; therefore, there is a need for preventive maintenance programmes. These are essential to “keep that engine alive” as we say. We are seeing a rising number of complaints from vehicle owners with models that are labelled as ‘compatible’ with E10 fuels. The problem is that water is drawn into the fuel system by the excess ethanol in the fuel. This eventually leads to phase-separation. That’s the formation of two distinct layers inside the fuel tank, one of which is water-rich. This causes ignition problems and other issues, such as internal corrosion.

“A preventative maintenance additive, such as Safeguard Ethanol Fuel Conditioner, will protect a wide number of models from the dangers of internal damage caused by E10 fuels.”