Melett has continued to increase its stockholding of turbocharger components, as it looks to support customers against the backdrop of a volatile raw materials market.

Melett’s goal is to provide consistent availability of products to meet the demands of the aftermarket. As global supply chain issues look set to continue to be challenging over the coming year, the company has been working to support its worldwide customers.

Raw material prices have conventionally been determined by the Global Price Index (GPI), with stockists adding their margin before selling to the manufacturing sector. If the GPI increases by 3% for example, stockists reserve the right to charge more for the raw materials, therefore increasing the cost for manufacturers.

Melett produces hundreds of thousands of turbocharger parts annually, using a variety of raw materials. Aluminium is used in the manufacture of compressor wheels and compressor housings, and cast iron is used in the manufacture of bearing housings, for example.

Nickel is the main element of the Inconel material used in the manufacture of turbine wheels as it can withstand the tough operating conditions and extreme temperatures of a modern turbocharger and, therefore, a significant part of the cost of the turbine wheel is based on the current market cost of nickel.

The price of cast iron, aluminium, nickel and copper have all risen by more than 50% in the past year alone. This volatility in the raw materials market, combined with rising costs of energy and transportation, continues to push up prices of automotive components globally.

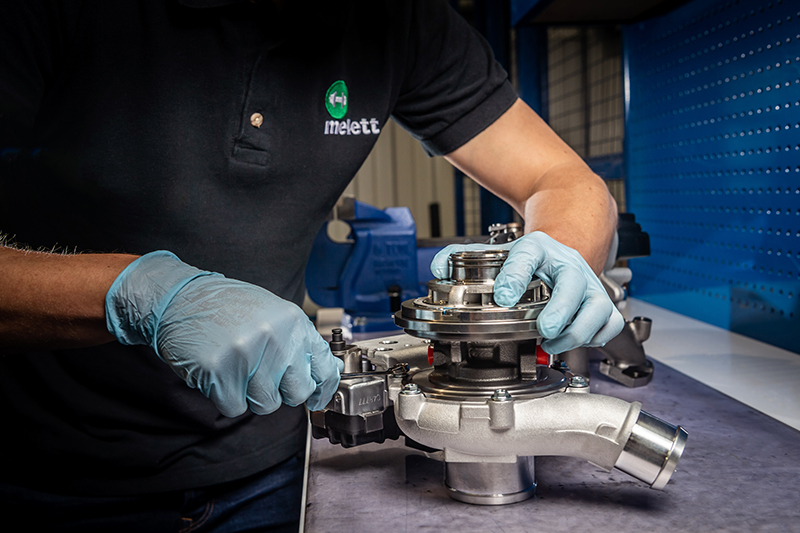

It is important that the correct material grade is used in the manufacture of turbocharger parts. Premature turbocharger failure is a common problem associated with the use of lower quality repair parts, which can be as a result of using lower grade raw materials. Melett understands the importance of using the correct materials and is committed to supporting the turbocharger repair market with the highest quality parts and service.

Andrew Frodsham, Melett Group Supply Chain Director, said: “There’s no escaping the fact that in most industries around the world prices are rising, and it’s not confined to a specific area or market sector.

“Over many years Melett has created a lean and effective supply chain. We have increased and enhanced our manufacturing capabilities, as well as expanding our domestic and international infrastructure to hold a greater range, and higher stocks of component parts, CHRAs and complete turbochargers.

“Given the current unpredictable world we live in, we will continue to build on the efficiencies we have created throughout our complex supply chain, working as best we can to mitigate against instability and ensure that disruption to our customers is minimal.

“The automotive sector and turbocharger repair market must resist the temptation to opt for lower priced, lower quality products, as this only serves to drive down standards in our market and damage the reputation of our industry.”