PMF talks to Shaftec about how following its ‘Reman Checklist’ can ensure that the best return on surcharge is achieved, with the company emphasising which defects make a component difficult or impossible to remanufacture. Being aware of this makes it easier for motor factors to advise their garage customers on correct component removal.

On surcharge, Tom Curtis, Shaftec Director, said, “Obtaining core in a fit state to remanufacture can render the surcharge obsolete, which is something we never want to do as it doesn’t benefit anyone in the chain. But a bit of knowledge and understanding when removing the part goes a long way towards ensuring that everyone gets the best out of the remanufacturing process.”

Shaftec works with safety critical parts which need to be disassembled, reprocessed, remanufactured and tested. Damaged core isn’t suitable, and so the company has invested heavily in the quality of the return and the source of collection. The importance of core quality varies from product to product. When remanufacturing driveshafts, the pots and CV joints are always replaced, so as long as they not broken or bent, they can be used. Similarly with calipers, as long as the casting isn’t badly corroded or cracked, they can generally be remanufactured as everything else is replaced.

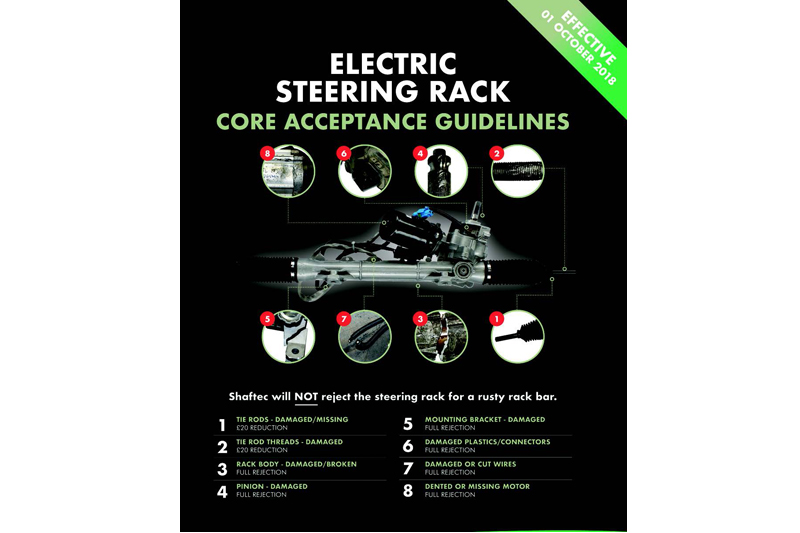

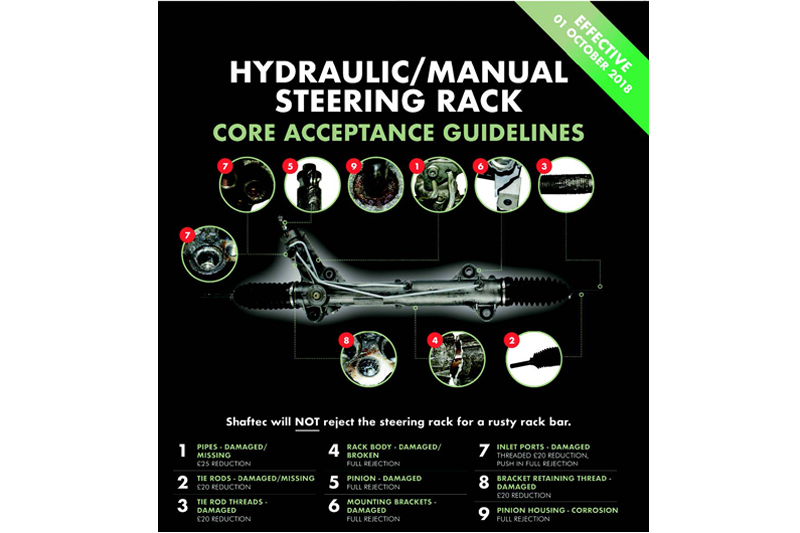

However, due to the complexity of both the product itself and the remanufacturing processes, for steering racks and pumps, Shaftec’s core return criteria is a lot more stringent. For example, when accepting core units, amongst other parts, the rack body, pinion, mounting brackets, inlet ports and bar must be completely undamaged.

“Let’s get one thing clear, we do not want to reject anything,” Tom continued. “We have a team in-house specifically tasked with sourcing core constantly, so we need as much of it as we can get, but if a returned unit is not in a condition where we can remanufacture to the required quality, then we unfortunately have to throw it away.

“We pride ourselves on working with the customer; we really want to make their lives as easy as possible. In line with this, we’ve significantly loosened the belt on our criteria over the years. The biggest change being that in October 2018, we lifted the criteria on corroded rack bars. Previously, if the rack bar beneath the gaiter was corroded or pitted due to water ingress – which would invariably mean that it had been contaminated through to the rack internals – it was rejected. We are now taking this particular criteria ‘on the nose’, and instead of passing the rejection backto the customer, we scrap them yet still honour the surcharge credit, even though the unit is useless to us.”

Joe Toakley, Area Sales Manager at Shaftec, added, “The best thing a motor factor can do when selling a rack is to have the conversation about making sure the old unit comes back in as good a condition as possible. All too often, we see rejections due to unit damage that could have only occurred once off the vehicle. Pinion damage is a perfect example, as is cutting pipes – which damages ports at the same time – and cutting electrical cables on electric racks.

Joe concluded, “The old units should be treated as new. After all, this piece of core is destined for a full remanufacture. The cost of some surcharges are greater than the cost of the unit itself and this should scream out the importance of good housekeeping.”